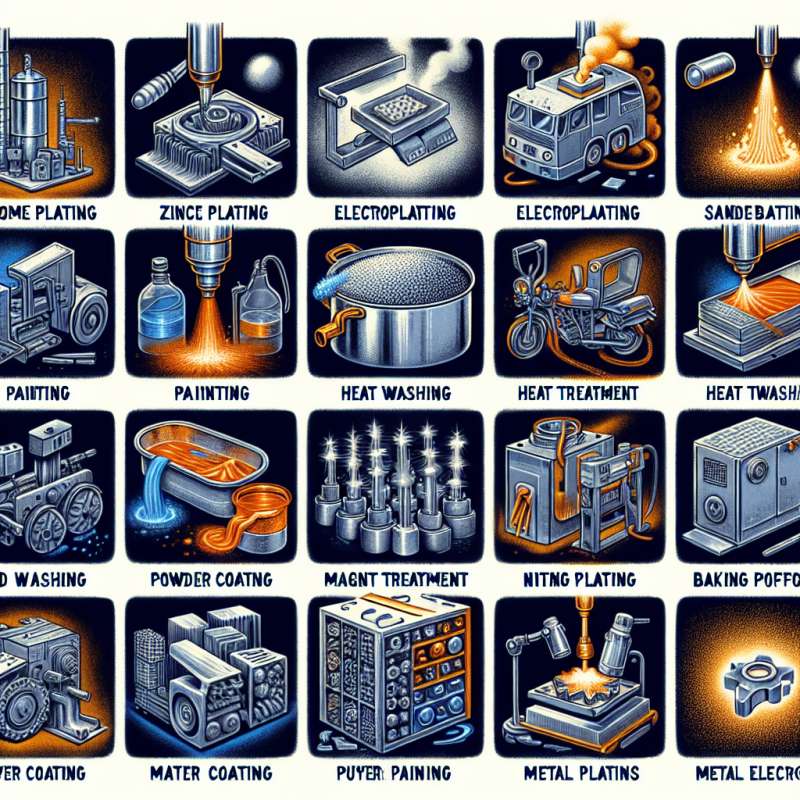

金屬製品在製造過程中常需要進行表面處理,以增加其耐腐蝕性、美觀性和耐磨性。其中,鍍鉻和鍍鋅是常見的表面處理方法,能有效防止金屬氧化和腐蝕。鍍鉻可以提高金屬的硬度和耐磨性,廣泛應用於汽車零件和家具配件等產品上。而鍍鋅則可以在金屬表面形成一層保護層,延長金屬製品的使用壽命。

除了鍍鉻和鍍鋅外,噴漆也是常見的表面處理方法之一。噴漆可以為金屬製品提供各種顏色和質感,使其更具美觀性和個性化。噴漆廣泛應用於汽車、家具和電器等產品的表面處理中。

金屬表面處理還包括其他方法,如電鍍、熱處理和陽極氧化等。這些方法可以改善金屬的表面性能,增加其耐磨性和耐腐蝕性。在製造過程中,選擇合適的表面處理技術對產品的質量和性能至關重要。

Translation:

Keywords: Metal, Surface treatment, Chrome plating, Galvanizing, Spray painting

Title: Application of Metal Surface Treatment Techniques

Article: Metal products often require surface treatment during the manufacturing process to increase their corrosion resistance, aesthetics, and wear resistance. Among them, chrome plating and galvanizing are common surface treatment methods that can effectively prevent metal oxidation and corrosion. Chrome plating can improve the hardness and wear resistance of metal, and is widely used in products such as automotive parts and furniture accessories. Galvanizing forms a protective layer on the metal surface, extending the lifespan of metal products.

In addition to chrome plating and galvanizing, spray painting is also a common surface treatment method. Spray painting can provide metal products with various colors and textures, making them more aesthetically pleasing and personalized. Spray painting is widely used in the surface treatment of products such as automobiles, furniture, and appliances.

Metal surface treatment also includes other methods such as electroplating, heat treatment, and anodizing. These methods can improve the surface performance of metal, increasing its wear resistance and corrosion resistance. Choosing the appropriate surface treatment technique is crucial for the quality and performance of products during the manufacturing process.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)