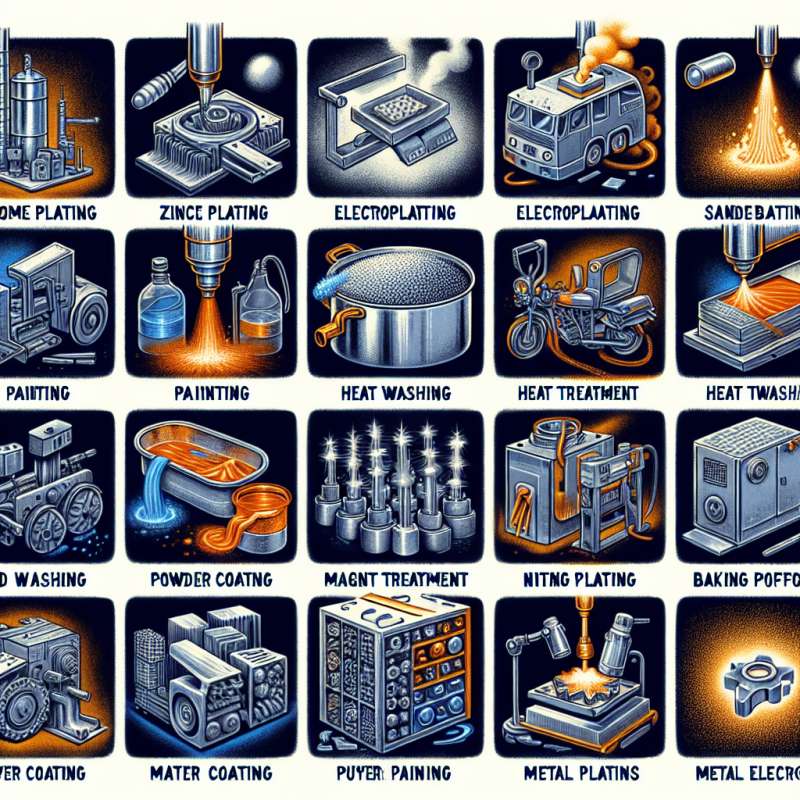

近年來,金屬製品表面處理在製造業中扮演著重要的角色。其中,洗螺絲代工、熱處理後拋光等技術不僅能提升產品的外觀質感,也能增加其耐用性和防銹性。

隨著科技的進步和市場需求的不斷變化,金屬製品表面處理領域也在不斷創新。未來,我們可以預見到更多的自動化和智能化技術應用於表面處理工藝中,以提高生產效率和品質一致性。同時,環保意識的提高也將推動更環保的表面處理方法的應用,例如脫脂和洗油除銹防銹技術的發展。

除此之外,隨著全球供應鏈的日益密切,金屬製品表面處理的國際合作也將成為一個重要趨勢。洗螺絲代工和熱處理後拋光等服務的跨國合作將為企業帶來更廣闊的市場和更多的合作機會。

總的來說,金屬製品表面處理行業將朝著更智能化、環保化和國際化的方向發展,為製造業的發展注入新的動力。

Keywords: Surface treatment, Screw washing subcontracting, Polishing after heat treatment

Title: Future Trends in Surface Treatment of Metal Products

Article: In recent years, surface treatment of metal products has played an important role in the manufacturing industry. Technologies such as screw washing subcontracting and polishing after heat treatment not only enhance the appearance and texture of products, but also increase their durability and rust resistance.

With the advancement of technology and the changing market demands, the field of surface treatment of metal products is constantly innovating. In the future, we can expect to see more automation and intelligent technologies applied in surface treatment processes to improve production efficiency and quality consistency. Additionally, the increasing environmental awareness will drive the application of more eco-friendly surface treatment methods, such as the development of degreasing and rust prevention technologies.

Furthermore, with the increasingly interconnected global supply chains, international cooperation in surface treatment of metal products will also become an important trend. Cross-border cooperation in services such as screw washing subcontracting and polishing after heat treatment will bring broader market opportunities and more collaboration prospects for businesses.

Overall, the surface treatment industry of metal products will evolve towards a more intelligent, environmentally friendly, and international direction, injecting new momentum into the development of the manufacturing industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)