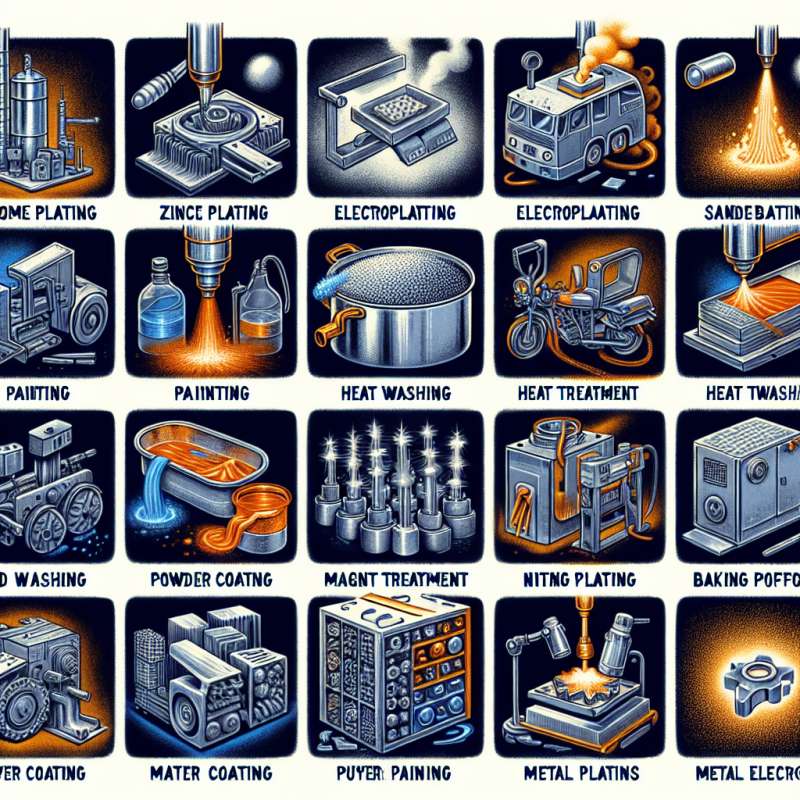

近年來,金屬製品表面處理在製造業中扮演著重要的角色,尤其是在外銷產品中更是不可或缺的一環。拋光研磨是一種常見的金屬製品表面處理技術,能夠提升產品的外觀質感和光澤度,使其更具吸引力。連續沖壓則是一種高效率的製造方法,能夠大量生產金屬容器等產品,符合外銷市場的需求。

未來金屬製品表面處理的趨勢將朝向更環保和高效率的方向發展。油壓技術的應用將逐漸取代傳統的機械加工方法,降低能源消耗和減少廢棄物產生。同時,金屬容器製造將更加注重產品的品質和功能性,以滿足不同市場的需求。

關鍵字: Export, Polishing and Grinding, Continuous Stamping, Stainless Steel Cutlery, Metal Utensils, Hydraulic Press, Metal Product Surface Treatment, Metal Container Manufacturing

Title: Future Trends in Metal Product Surface Treatment

Article: In recent years, metal product surface treatment has played an important role in the manufacturing industry, especially in the export of products. Polishing and grinding are common techniques used in metal product surface treatment, enhancing the appearance and gloss of products, making them more attractive. Continuous stamping is an efficient manufacturing method that can mass-produce metal containers and other products, meeting the demands of the export market.

The future trend of metal product surface treatment will focus on environmental friendliness and efficiency. The application of hydraulic press technology will gradually replace traditional mechanical processing methods, reducing energy consumption and waste generation. At the same time, metal container manufacturing will pay more attention to product quality and functionality to meet the needs of different markets.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)