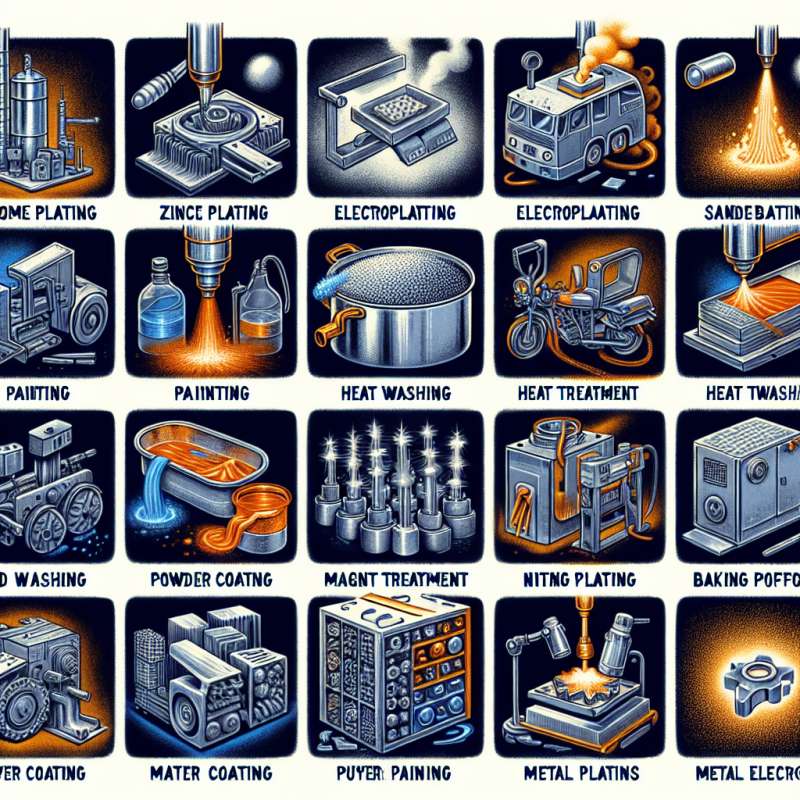

金屬製品在製造過程中常需要進行表面處理,以增加其耐腐蝕性和美觀度。表面處理的方法有很多種,包括鍍鉻、鍍鋅、噴漆、電鍍等。其中,鍍鉻是一種常用的方法,可以在金屬表面形成一層光亮的保護層,提高其耐腐蝕性和硬度。這對於汽車零件、家具五金等產品來說非常重要。

金屬表面處理還包括其他方法,如磷化、金屬電泳和金屬鍍層等。這些方法可以根據產品的具體要求進行選擇,以達到最佳的效果。例如,磷化可以在金屬表面形成一層磷化膜,提高其耐磨損性和附著力;金屬電泳則可以在金屬表面形成一層均勻的塗層,提高其耐腐蝕性和外觀。

總的來說,金屬表面處理對於提高產品的質量和使用壽命非常重要。選擇合適的表面處理方法可以讓產品擁有更好的性能和外觀,從而提高其市場競爭力。

關鍵字: surface treatment, metal, chromium plating

Title: The Importance of Surface Treatment for Metals

Article: Metal products often require surface treatment during the manufacturing process to increase their corrosion resistance and aesthetics. There are many methods of surface treatment, including chromium plating, zinc plating, painting, and electroplating. Among them, chromium plating is a commonly used method that can form a bright protective layer on the metal surface, enhancing its corrosion resistance and hardness. This is crucial for products such as automotive parts and furniture hardware.

Metal surface treatment also includes other methods such as phosphating, metal electrophoresis, and metal coating. These methods can be chosen according to the specific requirements of the product to achieve the best results. For example, phosphating can form a phosphating film on the metal surface, improving its wear resistance and adhesion; metal electrophoresis can form a uniform coating on the metal surface, enhancing its corrosion resistance and appearance.

In summary, metal surface treatment is crucial for improving the quality and lifespan of products. Choosing the appropriate surface treatment method can enhance the performance and appearance of the product, thereby increasing its market competitiveness.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)