近年來,金屬製品表面處理在製造業中扮演著重要的角色。隨著科技的進步和市場需求的不斷變化,金屬製品表面處理的技術也在不斷演進。其中,代工是一個重要的趨勢,許多製造商將金屬製品表面處理的工作外包給專業的代工廠商,以提高效率和降低成本。

除了代工之外,拋光也是金屬製品表面處理中常見的技術之一。通過拋光,可以使金屬表面更加光滑和亮麗,提升產品的質感和外觀。螺絲也是金屬製品中不可或缺的零件,其表面處理對於產品的組裝和使用起著至關重要的作用。

未來,金屬製品表面處理的趨勢將朝著更加環保和高效的方向發展。隨著人們對環境保護意識的提高,製造業將更加注重環保技術的應用,例如水性塗料和無鉻化處理技術。同時,隨著自動化技術的普及,金屬製品表面處理的自動化程度將逐漸提高,提高生產效率和品質。

Keywords: Parts, Metal product surface treatment, OEM

Title: Future Trends in Metal Product Surface Treatment

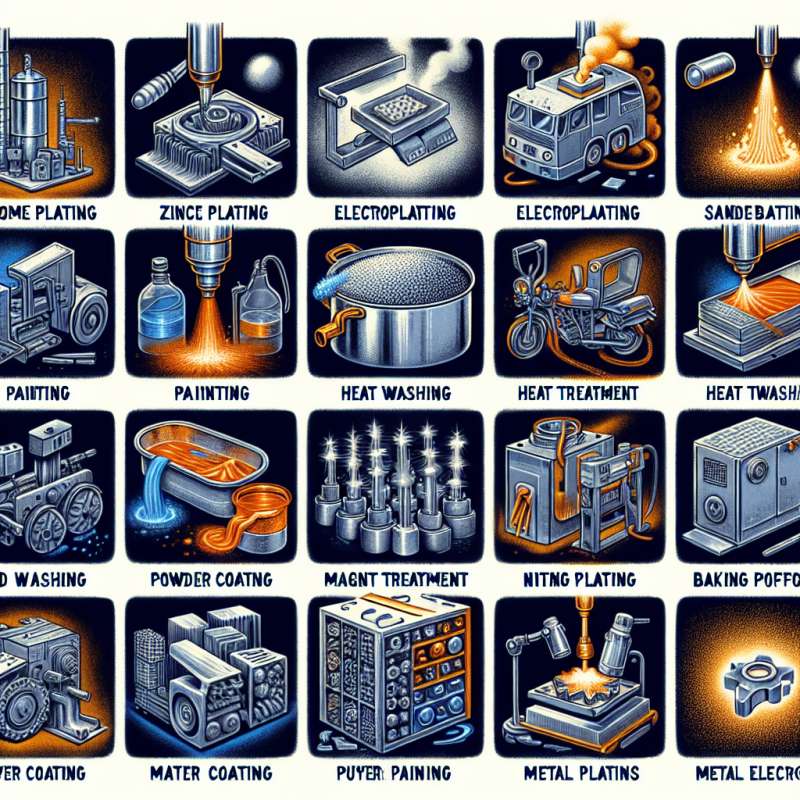

Article: In recent years, metal product surface treatment has played an important role in the manufacturing industry. With the advancement of technology and the constantly changing market demand, the technology of metal product surface treatment is also evolving. OEM is an important trend, where many manufacturers outsource the surface treatment of metal products to professional OEM factories to improve efficiency and reduce costs.

In addition to OEM, polishing is also a common technique in metal product surface treatment. Through polishing, the metal surface can be made smoother and more shiny, enhancing the texture and appearance of the product. Screws are also essential parts in metal products, and their surface treatment plays a crucial role in product assembly and use.

In the future, the trend of metal product surface treatment will move towards more environmentally friendly and efficient direction. With the increasing awareness of environmental protection, the manufacturing industry will pay more attention to the application of environmentally friendly technologies, such as water-based coatings and chromium-free treatment technology. At the same time, with the popularization of automation technology, the automation level of metal product surface treatment will gradually increase, improving production efficiency and quality.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)