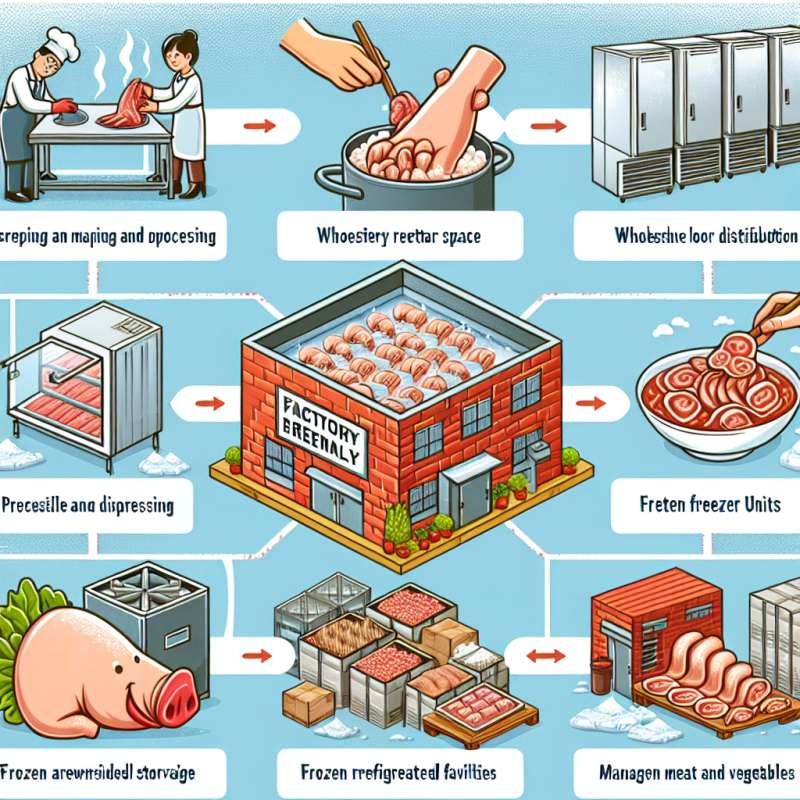

隨著現代人對食品安全和品質的要求越來越高,冷凍冷藏肉類製造業正進入一個全新的發展時代。為了滿足這些需求,企業必須持續提高加工技術,進行產品研發,建立符合國際標準的生產流程,並導入適當的品質管理系統,如ISO 9001。

冷凍冷藏肉類製造業是一個具有潛力的行業,其未來發展趨勢可以預見如下:

1. 加工技術的提升:隨著科技的發展,冷凍冷藏肉類製造企業將不斷改進其加工技術。這包括提供更高品質的冷凍冷藏肉類產品,減少加工損失,提高生產效率,並減少環境影響。

2. 產品研發的重要性:隨著消費者對於健康飲食的關注度提高,冷凍冷藏肉類製造業必須開發更健康的產品來滿足市場需求。這包括提供低脂肪、低鈉、無添加劑的產品,以及生產符合特殊飲食要求的肉類產品,如素食肉替代品。

3. 國際標準的遵從性:冷凍冷藏肉類製造業必須符合國際標準,如ISO 9001。這將有助於企業提高品質管理水平,確保生產流程的穩定性和可持續性。同時,這也意味著企業需要進行持續改進,以滿足不斷變化的市場需求和法規要求。

4. 進口市場的擴大:隨著人們對於各種口味的需求不斷增加,冷凍冷藏肉類製造業的進口市場將會擴大。這要求企業不僅提供高質量的產品,還要了解不同國家和地區的進口法規和文化特點。

5. 可持續發展的重視:隨著全球環境問題日益嚴重,冷凍冷藏肉類製造業需要重視可持續發展。這包括降低能源消耗、減少廢棄物、推廣循環經濟和減少碳排放。只有實現可持續發展,企業才能在未來取得長期競爭力。

總之,冷凍冷藏肉類製造業的未來將在提高加工技術、產品研發、遵從國際標準、拓展進口市場和重視可持續發展等方面持續發展。企業應該密切關注這些趨勢,並加強技術研發,提高品質管理水平,以滿足消費者日益增長的需求。

關鍵字: 9001, ISO, processing, research and development, frozen food manufacturing

標題: The Future Development Trends of Frozen Food Manufacturing

As the demand for food safety and quality continues to rise, the frozen food manufacturing industry is entering a new era of development. In order to meet these demands, companies must continuously improve their processing techniques, conduct research and development of products, establish production processes that comply with international standards, and implement appropriate quality management systems such as ISO 9001.

The frozen food manufacturing industry is a promising sector with the following future development trends:

1. Advancements in processing techniques: With the advancement of technology, frozen food manufacturing companies will continuously improve their processing techniques. This includes providing higher quality frozen food products, reducing processing losses, increasing production efficiency, and minimizing environmental impact.

2. Importance of product research and development: With increasing consumer focus on healthy eating, the frozen food manufacturing industry must develop healthier products to meet market demands. This includes offering low-fat, low-sodium, additive-free products, as well as producing meat alternatives that cater to specific dietary requirements, such as vegetarian options.

3. Compliance with international standards: Frozen food manufacturing companies must adhere to international standards such as ISO 9001. This will help companies improve their quality management levels, ensuring the stability and sustainability of production processes. Moreover, this also means that companies need to continuously improve to meet evolving market demands and regulatory requirements.

4. Expansion in import markets: As the demand for various flavors continues to grow, the import market for frozen food manufacturing will expand. This requires companies to not only provide high-quality products but also understand import regulations and cultural characteristics of different countries and regions.

5. Focus on sustainability: With increasing global environmental issues, frozen food manufacturing industry needs to prioritize sustainability. This includes reducing energy consumption, minimizing waste, promoting circular economy, and reducing carbon emissions. Only by achieving sustainable development can companies achieve long-term competitiveness in the future.

In conclusion, the future of frozen food manufacturing lies in improving processing techniques, product research and development, compliance with international standards, expanding import markets, and focusing on sustainability. Companies should closely monitor these trends and enhance technological research and development, improve quality management levels to meet the growing demands of consumers.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)