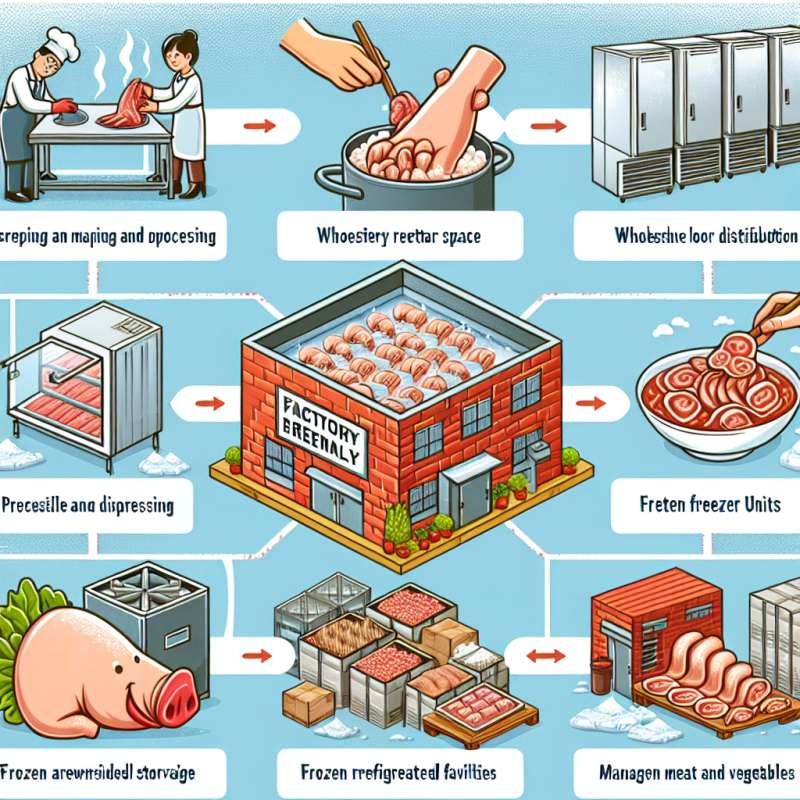

在現代食品製造業中,肉類製品的冷凍與冷藏過程扮演著重要的角色。首先,當肉類從供應商處收到後,製造商會將其進行初步處理,然後將其分類為需要冷凍或冷藏的產品。對於需要冷凍的肉類,製造商會將其放入冷凍室中,將其溫度降至極低的水平,以確保肉類能夠長時間保存而不會腐敗。而對於需要冷藏的肉類,製造商則會將其放入冷藏室中,保持在適當的溫度下,以延長其保質期。

在製造過程中,製造商會嚴格控制冷凍和冷藏的溫度和時間,以確保肉類製品的品質和安全性。此外,製造商還會定期檢查冷凍和冷藏設備,確保其正常運作,以避免肉類製品受到污染或變質。

總的來說,肉類的冷凍與冷藏製造過程是一個複雜而精密的過程,需要製造商嚴格控制各個環節,以確保最終產品的品質和安全性。

關鍵字: frozen, refrigerated, meat, manufacturing

Title: The Process of Meat Freezing and Refrigeration in Manufacturing

Article: In the modern food manufacturing industry, the freezing and refrigeration process of meat products plays a crucial role. Upon receiving meat from suppliers, manufacturers will first conduct initial processing before categorizing them into products that require freezing or refrigeration. For meats that require freezing, manufacturers will place them in a freezer to lower their temperature to extremely low levels to ensure long-term preservation without spoilage. On the other hand, meats that require refrigeration will be stored in a refrigerated room at an appropriate temperature to extend their shelf life.

During the manufacturing process, manufacturers strictly control the temperature and time of freezing and refrigeration to ensure the quality and safety of meat products. Additionally, they regularly inspect the freezing and refrigeration equipment to ensure proper operation and prevent contamination or spoilage of meat products.

In conclusion, the process of freezing and refrigerating meat products is complex and precise, requiring manufacturers to carefully control each step to ensure the quality and safety of the final products.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)