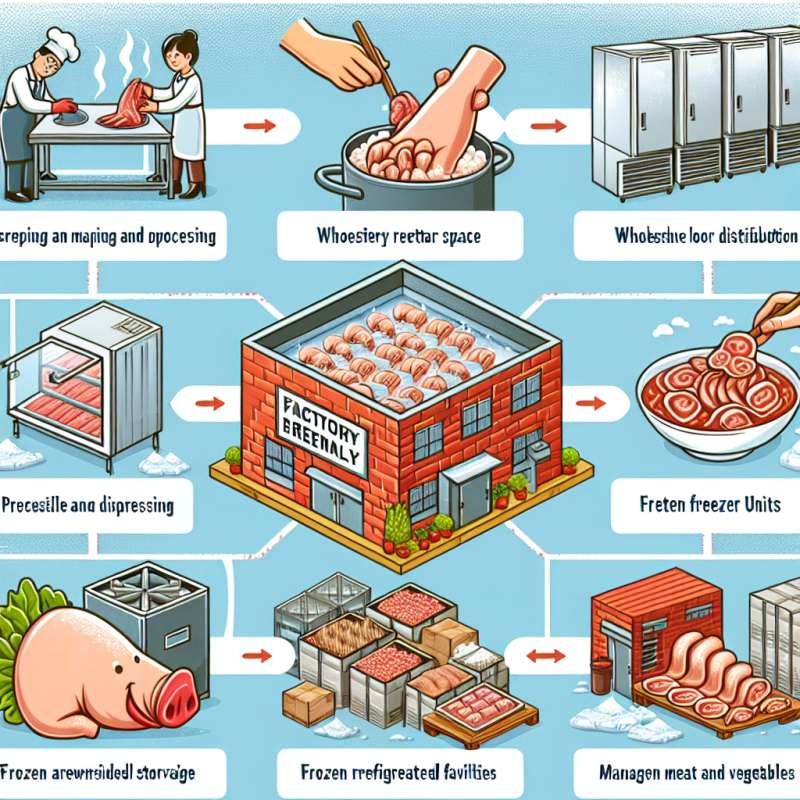

冷凍肉類製造是一個複雜的過程,需要嚴格的衛生標準和檢驗程序。首先,新鮮的肉類從供應商處購買後,會進行初步的清潔和處理。接著,肉類會被切割成適當的大小,以便進行後續的加工和包裝。

在製造過程中,肉類會經過不同的步驟,例如腌製、燻製或烹煮。這些步驟有助於提高肉類的口感和風味。接著,肉類會被冷凍或冷藏,以延長其保存期限。冷凍肉類可以在適當的溫度下保存數個月,而冷藏肉類則可以保存數天至數週。

最後,製造完成的肉類產品會進行包裝和標記,以確保產品的品質和衛生。在包裝過程中,會使用適當的包裝材料和技術,以確保產品不受外界污染。同時,每一批產品都會進行檢驗,以確保符合食品安全標準。

冷凍肉類製造過程需要嚴格的衛生措施和檢驗程序,以確保產品的品質和安全性。

Keywords: Frozen, Meat, Manufacturing

Title: The Process of Frozen Meat Manufacturing

Article: The process of frozen meat manufacturing is a complex one that requires strict hygiene standards and inspection procedures. Firstly, fresh meat is purchased from suppliers and undergoes initial cleaning and processing. The meat is then cut into appropriate sizes for further processing and packaging.

During the manufacturing process, the meat goes through different steps such as marinating, smoking, or cooking. These steps help enhance the texture and flavor of the meat. Subsequently, the meat is frozen or refrigerated to extend its shelf life. Frozen meat can be stored for several months at the right temperature, while refrigerated meat can last for days to weeks.

Finally, the finished meat products are packaged and labeled to ensure product quality and hygiene. Proper packaging materials and techniques are used to prevent contamination. Additionally, each batch of products undergoes inspection to ensure compliance with food safety standards.

The process of frozen meat manufacturing requires strict hygiene measures and inspection procedures to ensure product quality and safety.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)