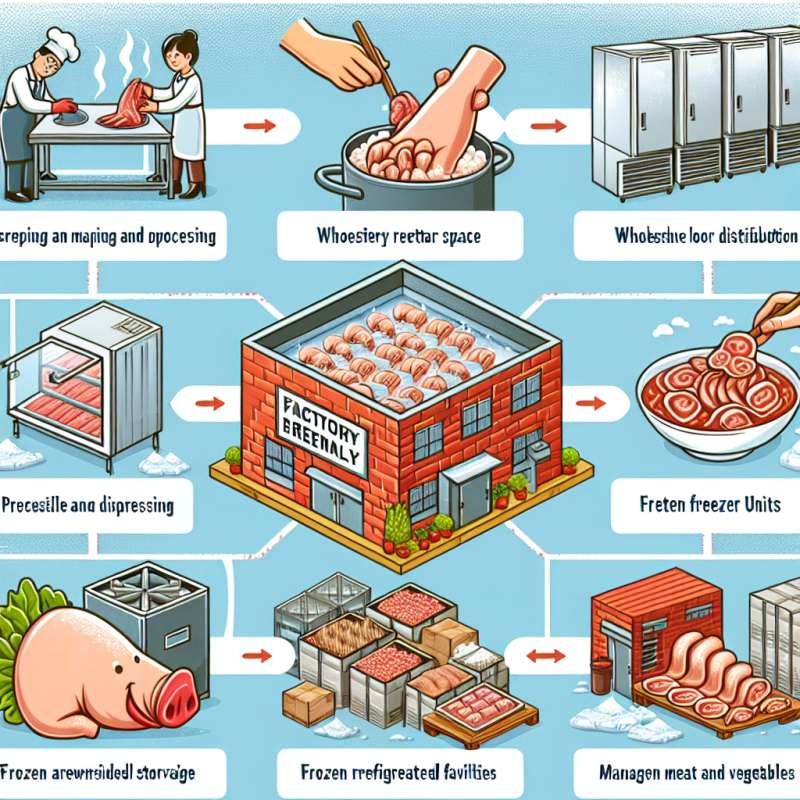

在現代社會中,冷凍肉類已成為人們日常生活中不可或缺的一部分。冷凍肉類是透過將新鮮的肉類製成適合長期保存的形式,以延長其保存期限。製造冷凍肉類的過程包括將新鮮的肉類進行處理、切割、包裝和冷凍等步驟。

首先,新鮮的肉類會經過嚴格的檢驗和清潔程序,以確保其品質符合標準。接著,肉類會根據不同的需求進行切割和處理,例如去除多餘的脂肪和骨頭。之後,肉類會被包裝成適合冷凍的包裝形式,通常是真空包裝或密封袋。

最後,製造商會將包裝好的肉類放入冷凍庫中進行冷凍。冷凍的過程能夠有效地降低肉類的溫度,使其在保存期間保持新鮮。冷凍肉類的保存期限通常比冷藏肉類更長,因此廣受消費者的喜愛。

透過以上製造過程,我們可以享受到新鮮的肉類,同時也能夠延長其保存期限,讓我們在需要時隨時取用。冷凍肉類的製造過程經過嚴格的控制和管理,確保了產品的品質和安全性。

Keywords: Frozen, Refrigerated, Meat, Manufacturing

Title: The Manufacturing Process of Frozen Meat

Article: In modern society, frozen meat has become an indispensable part of people's daily lives. Frozen meat is produced by processing fresh meat into a form suitable for long-term storage to extend its shelf life. The manufacturing process of frozen meat includes processing, cutting, packaging, and freezing fresh meat.

First, fresh meat undergoes strict inspection and cleaning procedures to ensure its quality meets standards. Then, the meat is cut and processed according to different requirements, such as removing excess fat and bones. Next, the meat is packaged in a form suitable for freezing, usually vacuum-sealed or in sealed bags.

Finally, manufacturers place the packaged meat in a freezer for freezing. The freezing process effectively lowers the temperature of the meat, keeping it fresh during storage. Frozen meat typically has a longer shelf life than refrigerated meat, making it popular among consumers.

Through the manufacturing process described above, we can enjoy fresh meat while extending its shelf life for convenient access when needed. The manufacturing process of frozen meat is rigorously controlled and managed to ensure product quality and safety.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)