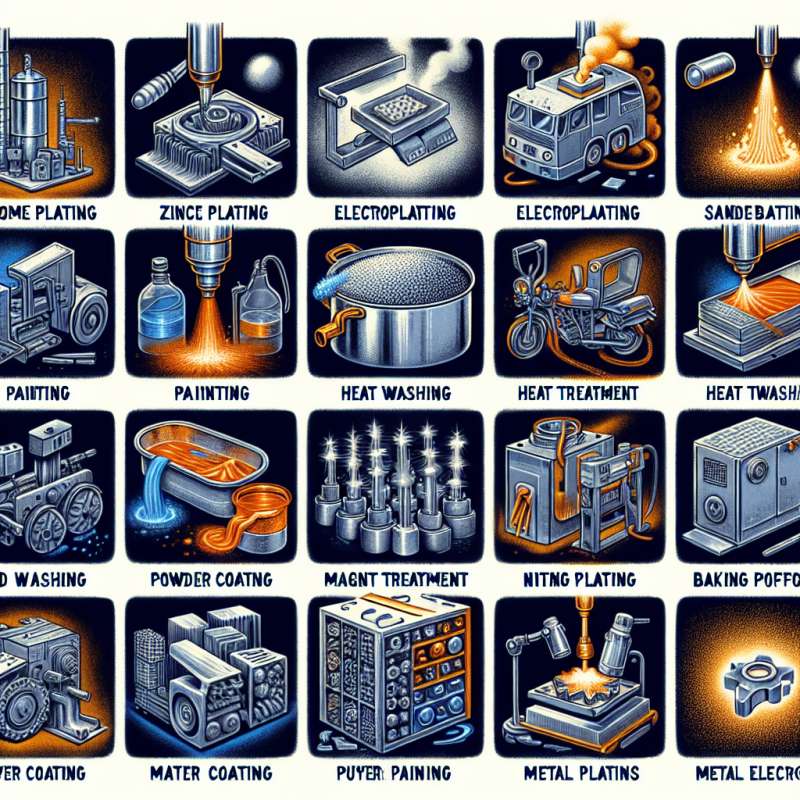

金屬製品在製造過程中經常需要進行表面處理,以增強其耐用性和外觀。其中,鍍鉻是一種常見的表面處理技術,通過在金屬表面形成一層鉻摻雜層,提供了耐蝕性和美觀性。除了鍍鉻,金屬的表面處理還包括鍍鋅、磷化、金屬鍍層等技術。

金屬表面處理的過程中,常見的方法包括噴漆、烤漆、電鍍、陽極氧化等。噴漆和烤漆是一種常見的表面處理技術,通過在金屬表面塗上一層漆,提高其美觀性和耐用性。電鍍則通過在金屬表面鍍上一層金屬或合金膜,提供較強的耐腐蝕性和耐磨性。

此外,金屬表面處理還包括噴砂、刷漆、氮化處理等技術。噴砂是通過高壓氣流將砂粒噴射到金屬表面,去除表面氧化層和污垢;刷漆是將漆刷在金屬表面,提高其保護性和美觀性;氮化處理則是通過將金屬浸泡在含氮氣氛下,改變金屬表面的化學性質,增加硬度和耐磨性。

綜上所述,金屬表面處理技術在製造業中扮演著重要角色,不僅可以提升金屬製品的品質和性能,還能延長其使用壽命和美觀度。

Keyword: metal, surface treatment, chrome plating

Title: Application of Metal Surface Treatment Technology

Article: Metal products often require surface treatment during the manufacturing process to enhance their durability and appearance. Among them, chrome plating is a common surface treatment technology that forms a layer of chromium-doped layer on the metal surface, providing corrosion resistance and aesthetics. In addition to chrome plating, surface treatment of metals also includes zinc plating, phosphating, metal coating, and other technologies.

Common methods in metal surface treatment processes include painting, baking, electroplating, anodizing, etc. Painting and baking are commonly used surface treatment technologies by coating a layer of paint on the metal surface to improve its aesthetics and durability. Electroplating involves depositing a layer of metal or alloy film on the metal surface to provide enhanced corrosion resistance and wear resistance.

Moreover, metal surface treatment also includes sandblasting, brushing, nitriding, and other techniques. Sandblasting removes surface oxidation and dirt by spraying sand particles onto the metal surface with high-pressure air flow; brushing involves painting on the metal surface to enhance protection and attractiveness; nitriding immerses the metal in a nitrogen atmosphere to alter the surface chemistry, increasing hardness and wear resistance.

In conclusion, metal surface treatment technology plays a significant role in the manufacturing industry, not only improving the quality and performance of metal products but also extending their lifespan and aesthetics.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)