金屬製品表面處理在半導體和管件產業中扮演著非常重要的角色。隨著科技的進步,半導體產品和管件在各個領域扮演著關鍵性的角色,因此對於這些產品的表面處理要求也越來越高。

金屬製品的表面處理可以改善其表面的性能和質量,延長其使用壽命,並提高其耐腐蝕性能。在半導體製造和管件產業中,由於產品需要高精度和高純度,因此表面處理技術更是至關重要。例如,半導體製造中的蝕刻和沉積工藝需要金屬表面具有特定的性能和光滑度,以確保產品的穩定性和可靠性。

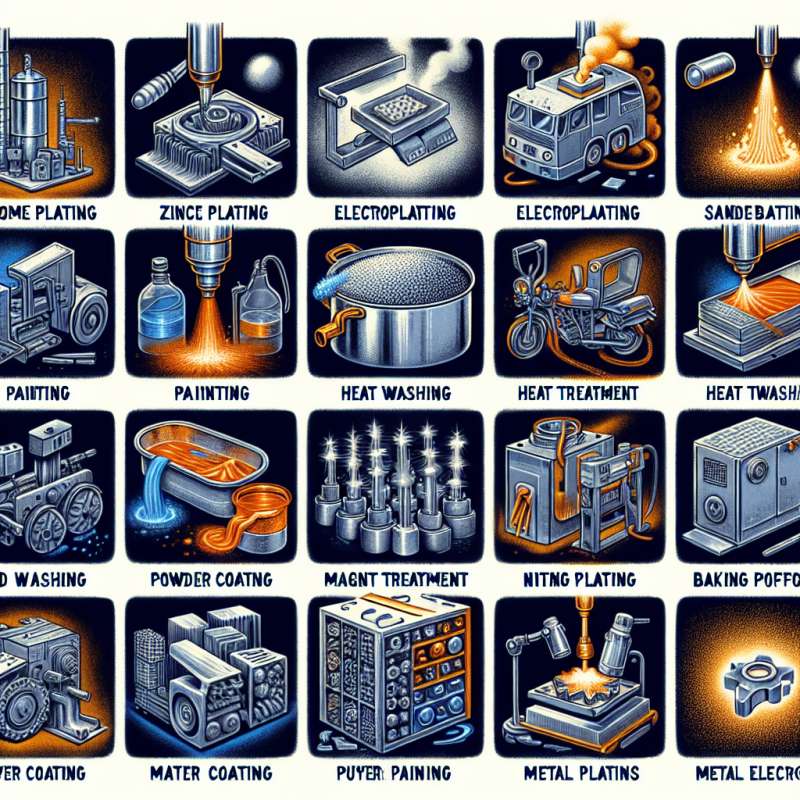

隨著未來科技的不斷發展,金屬製品表面處理技術也將不斷創新。例如,越來越多的產品將採用先進的鍍膜技術來提高其耐腐蝕性和耐磨損性。同時,納米技術的應用也將逐漸普及,使金屬表面的微細加工更加精確和高效。

總的來說,金屬製品表面處理在半導體和管件產業中具有極其重要的地位,未來的發展將朝著更為環保、節能和高效的方向發展。只有不斷注重技術創新和提升品質,才能滿足市場的需求,並在競爭激烈的行業中立於不敗之地。

Keywords: semiconductor, fittings, metal surface treatment

Title: The Importance of Metal Surface Treatment in the Semiconductor and Fittings Industries and Future Trends

Article: Metal surface treatment plays a crucial role in the semiconductor and fittings industries. With advancements in technology, semiconductor products and fittings play vital roles in various fields, leading to increasingly stringent requirements for surface treatment of these products.

Surface treatment of metal products can improve their performance, quality, prolong their lifespan, and enhance their corrosion resistance. In industries such as semiconductor manufacturing and fittings, where products require high precision and purity, surface treatment technologies are pivotal. For instance, etching and deposition processes in semiconductor manufacturing demand specific properties and smoothness of metal surfaces to ensure stability and reliability of products.

As technology continues to advance in the future, innovations in metal surface treatment technologies will continue to emerge. For example, more products will adopt advanced coating technologies to improve corrosion resistance and wear resistance. Additionally, the application of nanotechnology will become more widespread, allowing for more precise and efficient microprocessing of metal surfaces.

In conclusion, metal surface treatment holds a paramount position in the semiconductor and fittings industries, and future developments will focus on more environmentally friendly, energy-efficient, and high-performance directions. Only by continually emphasizing technological innovation and quality improvement can we meet market demands and remain competitive in the industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)