在製造業中,金屬製品的表面處理是一個非常重要的步驟。通常金屬製品在製程中需要進行多種表面處理,以增加其耐用性和美觀度。其中常見的表面處理方法包括鍍鉻、鍍鋅和噴漆等。

鍍鉻是一種常見的表面處理方法,它可以有效地防止金屬製品生鏽,並增加其硬度。鍍鋅則可以提供金屬的防腐蝕性能,尤其是在暴露於潮濕環境中。噴漆是一種外觀處理方法,可以使金屬製品看起來更美觀,並且可以根據客戶要求進行多種顏色的塗裝。

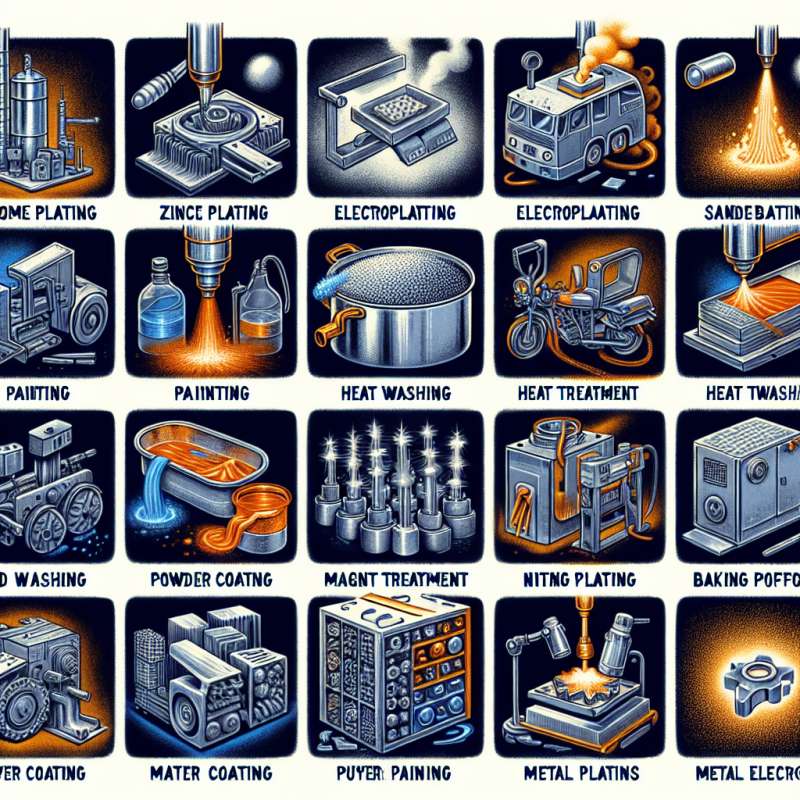

除了以上提到的方法外,還有許多其他表面處理方法,如電鍍、噴塗、噴砂、刷漆等。這些方法可以根據金屬製品的不同需求進行選擇和應用。通過適當的表面處理,可以有效地提高金屬製品的質量和功能性。

金屬表面處理對於延長金屬製品的使用壽命、提高表面硬度和美觀度都起著至關重要的作用。製造商應該根據金屬製品的具體需求來選擇適合的表面處理方法,以確保產品的品質和性能。

Keywords: Metal, Surface Treatment, Chrome Plating, Zinc Plating, Spray Painting

Title: The Importance of Metal Surface Treatment

Article: In the manufacturing industry, surface treatment of metal products is a crucial step. Metal products often require various surface treatments to enhance their durability and aesthetics. Common surface treatment methods include chrome plating, zinc plating, and spray painting.

Chrome plating is a common method that effectively prevents metal products from rusting and increases their hardness. Zinc plating provides corrosion resistance, especially in humid environments. Spray painting is a finishing method that improves the appearance of metal products and can be customized with various colors to meet customer requirements.

In addition to the mentioned methods, there are plenty of other surface treatment methods such as electroplating, powder coating, sandblasting, and brush painting. These methods can be chosen and applied based on the specific needs of metal products. Proper surface treatment can significantly enhance the quality and functionality of metal products.

Metal surface treatment plays a vital role in prolonging the lifespan, increasing surface hardness, and improving the aesthetics of metal products. Manufacturers should choose suitable surface treatment methods according to the specific requirements of metal products to ensure their quality and performance.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)