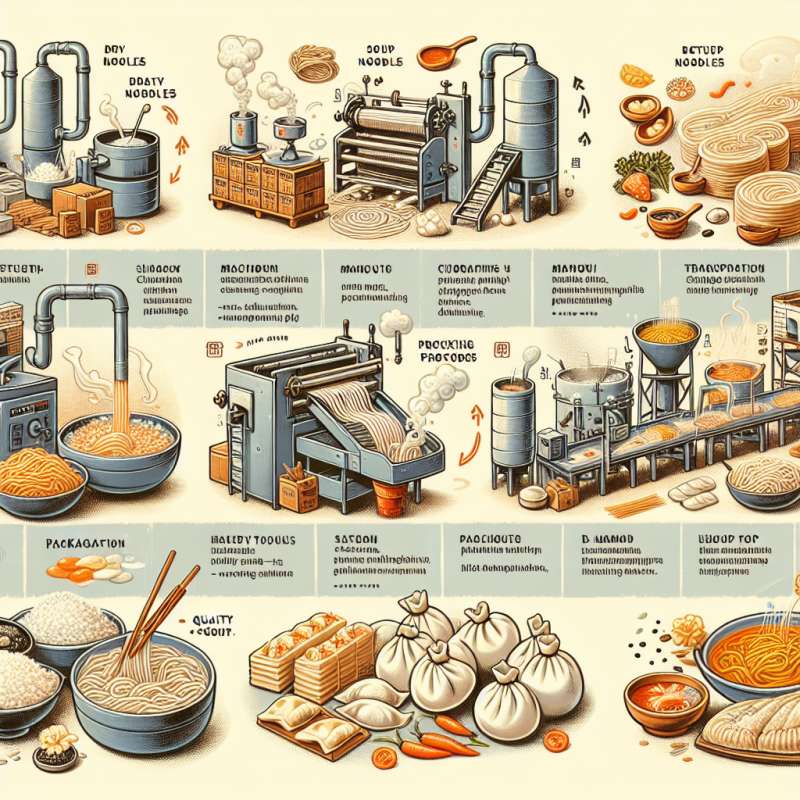

麵條製造是一個傳統卻技術性相對較高的食品生產過程。為了確保產品的質量,需要嚴格控制製程、衛生條件以及進行品質控制。同時,品牌商也非常重視麵條的包裝,以確保產品的新鮮度和安全性。

首先,麵條製造需要嚴格遵守一定的衛生條件。生產廠家必須保持乾淨的生產環境,並進行定期的清潔和消毒工作,以防止細菌污染。此外,員工應佩戴衛生帽、口罩,並保持良好的個人衛生,比如勤洗手等。這些措施能夠保證麵條的製造過程中不受污染,從而確保產品的安全性。

其次,品質控制是麵條製造過程中非常重要的一環。製造商需要對原材料進行嚴格的選擇,確保麵粉的質量達到標準。同時,在製程中需要控制適當的水分含量,以確保麵條的口感和質量。此外,還需要對麵條進行嚴格的檢測和檢驗,如在產品上進行拉伸、烹煮測試等,以確保產品符合標準。

最後,包裝對於麵條產品的長期保存和運輸非常重要。麵條製造商需要選擇適當的包裝材料和包裝方式,以確保產品的新鮮度和品質。通常,麵條裝在密封袋內,再放入紙盒或塑料袋中。這種包裝方式既能保護麵條不受外界潮濕和污染,同時也方便了產品的運輸和存儲。

總結來說,麵條製造不僅需要嚴格控制製程和衛生條件,同時也需要進行全面的品質控制和適當的包裝。這樣才能確保麵條的品質和安全性,並滿足消費者對於食品的高要求。

關鍵字: Noodle production, Quality control, Packaging

標題: Quality Control and Packaging in Noodle Production

Noodle production is a traditional yet relatively technical food manufacturing process. To ensure the quality of the products, strict control over the production process, sanitation conditions, and quality control is necessary. Additionally, noodle manufacturers place great importance on packaging to maintain product freshness and safety.

Firstly, maintaining proper sanitation conditions is crucial in noodle production. Manufacturers must maintain a clean production environment and perform regular cleaning and disinfection to prevent bacterial contamination. Employees are required to wear hairnets, masks, and practice good personal hygiene, such as frequent handwashing. These measures guarantee that noodles are not contaminated during the manufacturing process, ensuring product safety.

Secondly, quality control is an integral part of noodle production. Manufacturers need to carefully select raw materials, ensuring the quality of the flour meets standards. Controlling the appropriate moisture content during processing is important to ensure the desired texture and quality of the noodles. Additionally, rigorous testing and inspection of the noodles, such as stretching or cooking tests, ensures that they meet the standards.

Lastly, packaging plays a vital role in long-term preservation and transport of noodle products. Manufacturers need to choose suitable packaging materials and methods to maintain product freshness and quality. Typically, noodles are packaged in sealed bags, then placed in paper boxes or plastic bags. This packaging method protects the noodles from external moisture and contamination, facilitating transportation and storage.

In conclusion, noodle production requires strict control over the production process, sanitation conditions, comprehensive quality control, and appropriate packaging. These measures ensure the quality and safety of the noodles, meeting consumers' high expectations for food products.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)