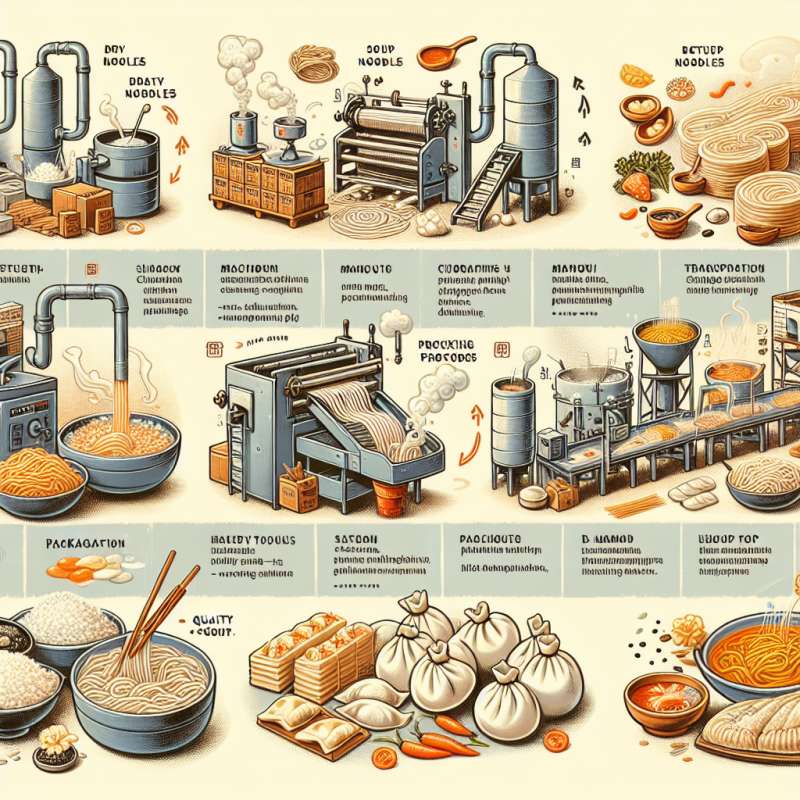

在麵食品製造過程中,品質控制是非常重要的環節。從麵粉的選擇開始,就需要嚴格控制原料的品質。只有選擇優質的麵粉,才能製造出口感好、口感細膩的麵食品。麵條製造過程中,麵條機械的運作也需要嚴格控制,確保每一條麵條的質量均勻一致。

在製造乾麵、湯麵、油條等不同種類的麵食品時,衛生條件也是至關重要的。廠房的清潔環境、生產工具的消毒以及員工的衛生狀況都需要嚴格把關,以確保製造出的麵食品符合衛生標準。

除了生產過程中的品質控制外,包裝和運輸環節也是影響麵食品品質的重要因素。適當的包裝可以保護麵食品不受外界污染,適當的運輸方式可以確保麵食品在運送過程中不受損壞。

總的來說,麵食品製造過程中的品質控制是一個環環相扣的過程,需要從原料選擇到生產過程再到包裝和運輸環節都嚴格把關,才能生產出優質的麵食品。

關鍵字: Noodles, Noodle manufacturing, Quality control

Title: Quality Control in Noodle Production

Article: In the process of noodle production, quality control is a crucial aspect. It all starts with the selection of flour, where strict control of the quality of raw materials is necessary. Only by choosing high-quality flour can we produce noodles with a good texture and delicate taste. During the noodle manufacturing process, the operation of noodle machinery also needs to be strictly controlled to ensure consistent quality of each noodle.

When producing different types of noodles such as dry noodles, soup noodles, and fried dough sticks, hygiene conditions are also essential. The cleanliness of the factory environment, disinfection of production tools, and the hygiene of employees all need to be strictly monitored to ensure that the produced noodles meet hygiene standards.

In addition to quality control during production, packaging and transportation are also important factors affecting the quality of noodles. Proper packaging can protect noodles from external contamination, and appropriate transportation methods can ensure that noodles are not damaged during transport.

Overall, quality control in the noodle production process is a comprehensive process that requires strict control from raw material selection to production and packaging to transportation in order to produce high-quality noodles.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)