麵條製造是一個複雜的過程,其中麵粉選擇和品質控制是非常重要的關鍵步驟。首先,麵條的質量取決於所選擇的麵粉。不同的麵粉有不同的蛋白質含量和質地,這將直接影響到麵條的口感和彈性。因此,在麵粉選擇階段,製造商需要仔細挑選適合自己產品的麵粉種類。

一旦選擇了適合的麵粉,品質控制就變得至關重要。製造商需要確保麵粉的質量穩定,這包括檢查麵粉的水分含量、蛋白質含量和細度。這些因素將直接影響到麵條的成品質量。為了確保一致的產品質量,製造商需要建立嚴格的品質控制標準和程序,並進行定期的檢測和檢驗。

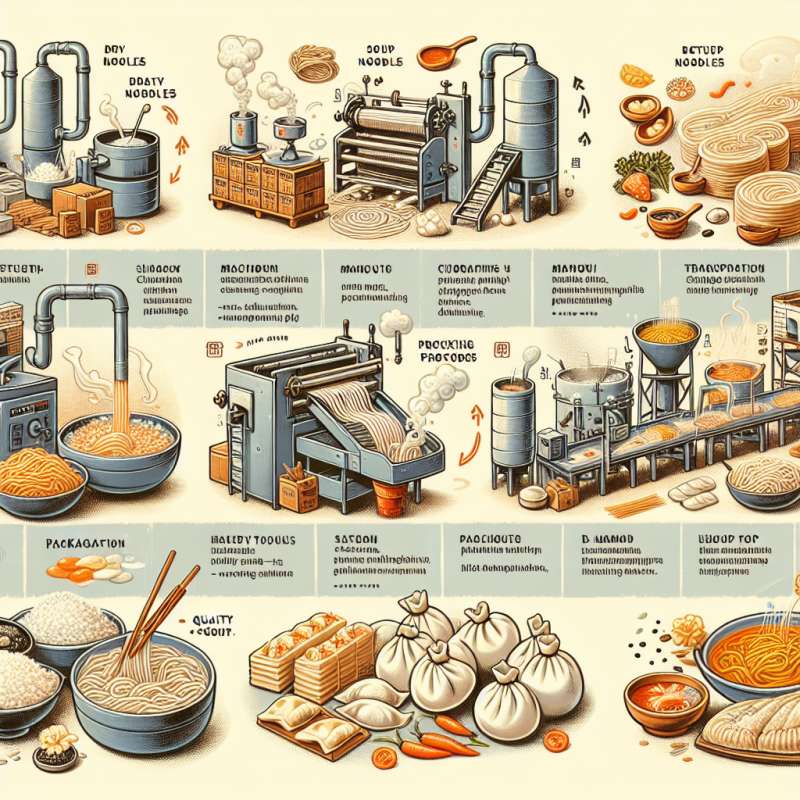

除了麵粉選擇和品質控制外,製造商還需要關注其他方面,如麵條機械的運作、包裝和運輸等。然而,麵粉選擇和品質控制仍然是確保高品質麵條製造的關鍵步驟。

English:

Keywords: Noodle manufacturing, Flour selection, Quality control

Title: Key to Noodle Manufacturing: Flour Selection and Quality Control

Article: Noodle manufacturing is a complex process, in which flour selection and quality control are crucial steps. Firstly, the quality of noodles depends on the chosen flour. Different flours have different protein content and texture, which directly affect the taste and elasticity of the noodles. Therefore, during the flour selection stage, manufacturers need to carefully choose the type of flour that suits their products.

Once the right flour is chosen, quality control becomes paramount. Manufacturers need to ensure the stability of flour quality, including checking the moisture content, protein content, and fineness of the flour. These factors directly impact the final product quality of the noodles. To ensure consistent product quality, manufacturers need to establish strict quality control standards and procedures, and conduct regular testing and inspection.

In addition to flour selection and quality control, manufacturers also need to pay attention to other aspects such as the operation of noodle machinery, packaging, and transportation. However, flour selection and quality control remain the key steps in ensuring high-quality noodle manufacturing.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)