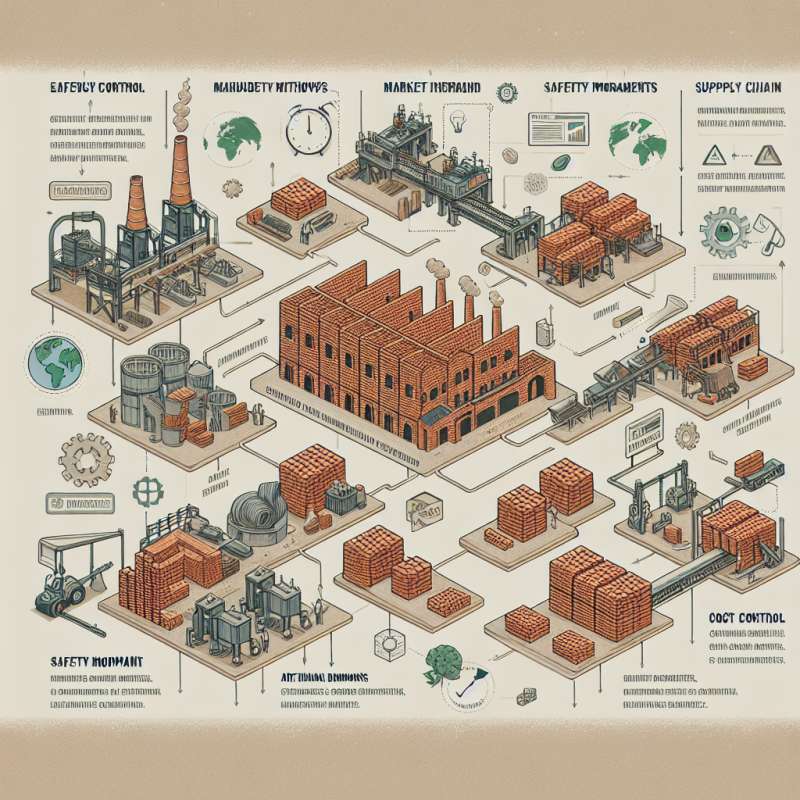

現代建築材料在製造過程中使用了高效率的生產線,這使得製程更加自動化、成本更容易控制、效率更容易提升,同時還能確保產品品質控制、測試及環保。建築材料的生產過程涉及到原料的選擇、工藝的設計、製程的改善以及安全措施的落實。

在建築材料的生產線上,首先需要選擇合適的原料,這些原料包括磚瓦、水泥、骨料等,這些原料的質量直接影響到最終產品的品質。通過科學的工藝設計和製程改進,可以提高產品的品質控制,同時測試也可以確保產品達到設定的標準。

在製造過程中,碳足跡是一項關鍵指標,這需要對生產過程進行環保措施。有效的環保措施可以減少資源的浪費,同時也可以減少對環境的影響,符合現代社會的可持續發展需求。

耐久性是建築材料的重要特性之一,它影響到建築物的使用壽命。通過選擇高質量的原料和合理的製程,建築材料可以達到較高的耐久性要求,提供持久的保護性能。

市場需求是影響建築材料製造的一個關鍵因素,生產線必須能夠靈活適應市場變化。透過有效的供應鏈管理和成本控制,可以在市場需求變動時快速調整產品定位和生產計劃。

總結來說,現代建築材料的製造和生產過程涉及到許多關鍵要素,例如生產線、原料選擇、工藝設計、品質控制、測試、環保、耐久性、市場需求、供應鏈、成本控制等等。透過有效的技術應用和安全措施,可以實現生產過程的自動化和確保生產線的安全運行。

關鍵字: Manufacturing, Construction materials, Production line

Title: The Manufacturing and Production Process of Modern Building Materials Production Line

Article:

Modern building materials are manufactured using efficient production lines, which automate the process, enable cost control, improve efficiency, while ensuring quality control, testing, and environmental protection. The production process of building materials involves the selection of raw materials, design of production processes, process improvement, and implementation of safety measures.

In the production line of building materials, the first step is to select suitable raw materials, including bricks, tiles, cement, aggregates, etc., as the quality of these raw materials directly affects the final product quality. Scientific process design and process improvement can enhance quality control, while testing ensures products meet the defined standards.

During the manufacturing process, the carbon footprint is a crucial indicator that requires environmental protection measures. Effective environmental protection measures can reduce resource waste and minimize environmental impact, aligning with the sustainable development needs of modern society.

Durability is an essential characteristic of building materials, as it influences the lifespan of structures. By selecting high-quality raw materials and implementing appropriate processes, building materials can meet high durability requirements, providing long-lasting protection.

Market demand is a key factor influencing the manufacturing of building materials, and production lines must be able to adapt flexibly to market changes. Through effective supply chain management and cost control, product positioning and production plans can be adjusted quickly in response to market fluctuations.

In conclusion, the manufacturing and production process of modern building materials involves various critical elements, such as production lines, raw material selection, process design, quality control, testing, environmental protection, durability, market demand, supply chain, and cost control. Through the application of efficient technology and safety measures, automation can be achieved in the production process while ensuring the safe operation of the production line.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)