磚瓦是一種常見的建築材料,其製造過程需要嚴格的品質控制以確保產品符合標準。在磚瓦生產過程中,原料的選擇至關重要。不同類型的原料會影響最終產品的性能和外觀,因此需要定期的測試和評估。

製造磚瓦的工藝和製程也很重要。生產線上的設備應該處於良好狀態,以確保產品的一致性和質量。品質控制技術應該針對每個製造階段進行,並確保符合標準。

為了提高效率和控制成本,許多製造商已經開始導入自動化技術。這不僅可以提高生產效率,還可以降低人為錯誤的機會。同時,製造商也應該關注環保和碳足跡議題,採取相應的措施以降低對環境的影響。

在市場需求方面,磚瓦的耐久性和外觀對消費者非常重要。因此,製造商應該密切關注趨勢,不斷提升產品的品質和設計水平,以滿足客戶的需求。

總的來說,磚瓦製造是一個複雜的過程,需要不斷改進和優化。通過嚴格的品質控制,製造商可以確保產品的高質量,滿足市場需求。

Translation:

Keywords: Manufacturing, Product, Quality Control

Title: Quality Control in Brick Manufacturing

Article:

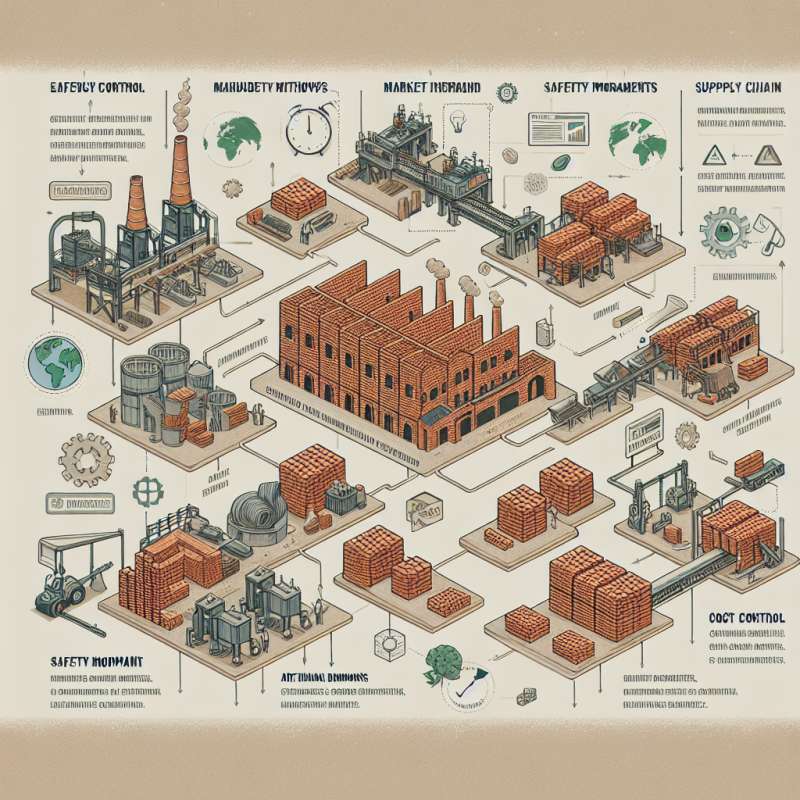

Bricks are a common building material, and the manufacturing process requires strict quality control to ensure the products meet standards. In the production of bricks, the selection of raw materials is crucial. Different types of raw materials will affect the performance and appearance of the final product, so regular testing and evaluation are necessary.

The manufacturing process and procedures in making bricks are also crucial. The equipment on the production line should be in good condition to ensure consistency and quality of the products. Quality control techniques should be implemented for each manufacturing stage to ensure compliance with standards.

To improve efficiency and control costs, many manufacturers have started to implement automation technology. This not only increases production efficiency but also reduces the chances of human errors. Meanwhile, manufacturers should also pay attention to environmental protection and carbon footprint issues, taking corresponding measures to minimize the impact on the environment.

In terms of market demand, the durability and appearance of bricks are essential to consumers. Therefore, manufacturers should closely monitor trends, continuously enhance product quality, and design to meet customer needs.

Overall, brick manufacturing is a complex process that requires continual improvement and optimization. Through strict quality control, manufacturers can ensure high-quality products that meet market demand.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)