鋼材在製程中經常需要進行熱處理,以改變其微結構及提升硬度和強度。其中,淬火溫度是一個重要的參數,它決定了鋼材的最終硬度和強度。在高溫下淬火可以使鋼材快速冷卻,形成硬而脆的結構,提高硬度,但同時也容易產生裂紋。而低溫淬火則可以降低硬度,但提高韌性。微結構是決定鋼材性能的關鍵因素之一,不同的熱處理條件會導致不同的微結構,進而影響硬度和強度。因此,在進行熱處理時,需要根據具體的應用需求來選擇適合的淬火溫度,以達到最佳的硬度和強度效果。

Keywords: Heat treatment, Quenching temperature, Microstructure, Hardness, Strength

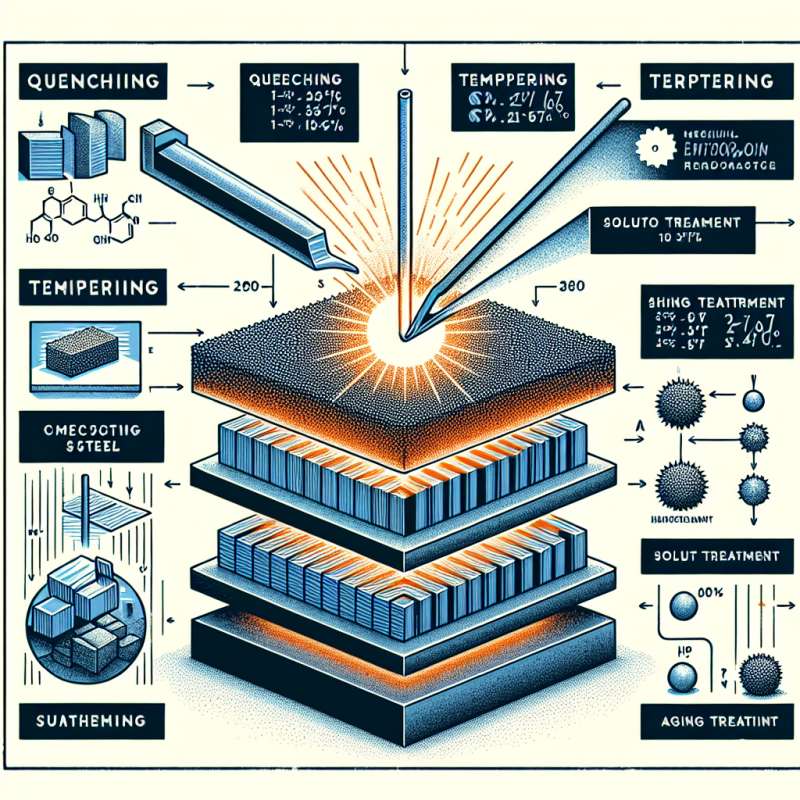

Title: The Influence of Heat Treatment on Microstructure, Hardness, and Strength of Steel

Article: Steel often requires heat treatment in the manufacturing process to alter its microstructure and enhance its hardness and strength. Among them, quenching temperature is a crucial parameter that determines the final hardness and strength of the steel. Quenching at high temperatures can rapidly cool the steel, forming a hard and brittle structure, increasing hardness, but also prone to cracking. On the other hand, quenching at low temperatures can reduce hardness but improve toughness. Microstructure is one of the key factors determining the performance of steel, and different heat treatment conditions will result in different microstructures, thereby affecting hardness and strength. Therefore, when conducting heat treatment, it is essential to choose the appropriate quenching temperature based on specific application requirements to achieve the optimal hardness and strength effects.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)