ISO 9001是一項國際標準,它主要關注的是品質管理系統。許多工廠和企業都希望通過取得ISO 9001認證來證明其產品和服務的高品質水平。這項認證特別對於零組件製造業來說尤為重要,因為它們的產品通常作為其他產品的一部分,品質的高低對整個產品的性能有直接的影響。因此,ISO 9001認證對於這些工廠來說是非常有價值的。

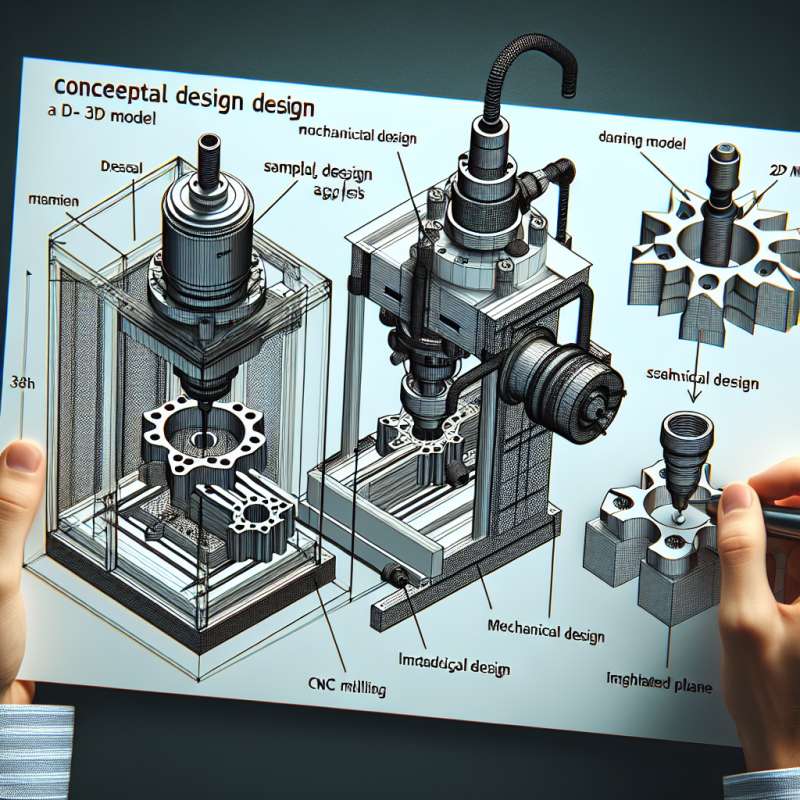

零組件工廠通常需要制定細致的設計規範,以確保產品的品質和標準。這些設計規範可能包括材料選擇、尺寸要求、製造過程和測試方法等。資訊技術在這個過程中起著重要的作用,它可以幫助工程師和設計師確保產品設計符合ISO 9001標準。例如,設計師可以使用CAD軟件進行三維建模,進一步優化產品設計並減少錯誤。

未來,隨著技術的發展和市場需求的變化,零組件工廠將面臨一些新的挑戰和機遇。其中一個關鍵趨勢是自動化製造。隨著機器人技術和人工智能的進步,工廠可以更有效地生產零組件,提高生產效率和品質。同時,資訊系統和物聯網的應用也讓零組件的設計和製造更加智能化和可追蹤,可以更容易地追踪產品的品質和生產過程。

另一個重要的趨勢是國際貿易和進口。許多零組件工廠依賴於海外供應商提供關鍵材料和部件。因此,了解國際貿易政策、掌握進口手續和熟悉國際市場需求是非常重要的。同時,科技的進步也讓國際貿易更加便捷和全球化,在進口方面帶來了更多的機會。

總結而言,ISO 9001資訊設計在工廠零組件行業中具有重要的地位。設計規範和資訊技術的應用有助於確保產品的高品質和標準。未來,自動化製造和國際貿易將成為行業的重要趨勢,這將為零組件工廠帶來新的發展機遇。

關鍵字: ISO, component, 9001, factory, design, uncategorized wholesale of other machinery and equipment

標題: ISO 9001 Information Design: Future Trends in Factory Components

ISO 9001 is an international standard that focuses on quality management systems. Many factories and businesses seek ISO 9001 certification to demonstrate the high level of quality of their products and services. This certification is particularly important for the component manufacturing industry, as their products are often part of other products and the quality directly impacts the performance of the whole. Therefore, ISO 9001 certification holds great value for these factories.

Component factories typically need to develop detailed design specifications to ensure the quality and standards of their products. These design specifications may include material selection, dimension requirements, manufacturing processes, and testing methods. Information technology plays a crucial role in this process, aiding engineers and designers in ensuring that the product design complies with ISO 9001 standards. For instance, designers can utilize CAD software for 3D modeling to further optimize product design and reduce errors.

In the future, component factories will face new challenges and opportunities as technology advances and market demands change. One key trend is automated manufacturing. With advancements in robotics and artificial intelligence, factories can produce components more efficiently, improving production efficiency and quality. Simultaneously, the application of information systems and the Internet of Things enables intelligent and traceable design and manufacturing of components, facilitating easier tracking of product quality and production processes.

Another significant trend is international trade and imports. Many component factories rely on overseas suppliers for critical materials and parts. Therefore, understanding international trade policies, mastering import procedures, and being familiar with international market demands are crucial. Additionally, technological advancements have made international trade more convenient and globalized, presenting more opportunities in imports.

In conclusion, ISO 9001 information design holds a crucial position in the factory component industry. Design specifications and the application of information technology contribute to ensuring the high quality and standards of products. In the future, automated manufacturing and international trade will be important trends in the industry, bringing new development opportunities for component factories.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)