隨著科技的進步和產業的發展,金屬加工產業正逐漸走向自動化和智能化。其中,鎢鋼刀具處理和CNC技術的應用已成為金屬加工領域中不可或缺的關鍵技術之一。鎢鋼刀具處理能夠提高刀具的硬度和耐磨性,延長刀具的使用壽命,提高加工效率和產品質量。而CNC技術則可以實現金屬加工過程的自動化控制,提高加工精度和生產效率。

此外,金屬加工機械設備的維修及安裝也是金屬加工產業中不可或缺的環節。隨著金屬加工機械設備的不斷更新和升級,專業的維修和安裝服務將成為金屬加工廠房的重要保障。尤其是對於中古機器和歐洲進口機械的維修和安裝需求更加迫切。

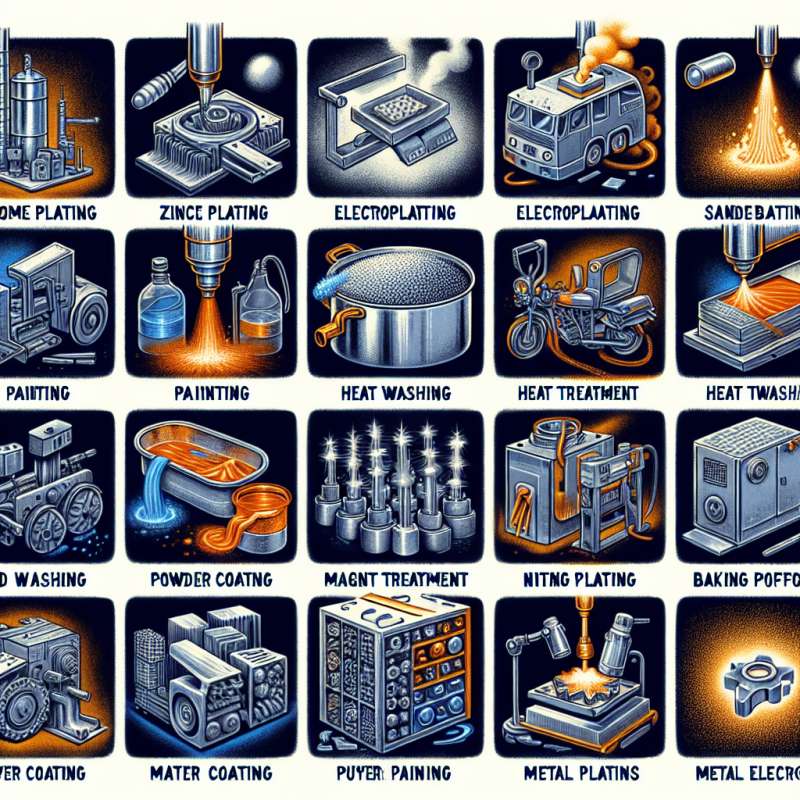

在未來,金屬製品表面處理和金屬加工機械設備維修及安裝將成為金屬加工產業的重要發展方向。透過不斷的技術創新和專業訓練,金屬加工業將能夠應對市場需求的變化,提高產品質量和生產效率,實現更好的發展。

Keywords: Tungsten steel tool processing, CNC, Metal processing machinery equipment maintenance and installation

Title: Future Development Trends in the Metal Processing Industry

Article: With the advancement of technology and the development of industries, the metal processing industry is gradually moving towards automation and intelligence. Among them, tungsten steel tool processing and the application of CNC technology have become indispensable key technologies in the field of metal processing. Tungsten steel tool processing can improve the hardness and wear resistance of tools, extend the tool's service life, improve processing efficiency, and product quality. CNC technology can achieve automated control of the metal processing process, improving processing accuracy and production efficiency.

In addition, the maintenance and installation of metal processing machinery equipment are also indispensable in the metal processing industry. With the continuous updating and upgrading of metal processing machinery equipment, professional maintenance and installation services will become an important guarantee for metal processing plants. Especially for the maintenance and installation needs of used machinery and European imported machinery are more urgent.

In the future, metal product surface treatment and maintenance and installation of metal processing machinery equipment will become important development directions in the metal processing industry. Through continuous technological innovation and professional training, the metal processing industry will be able to respond to changes in market demand, improve product quality and production efficiency, and achieve better development.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)