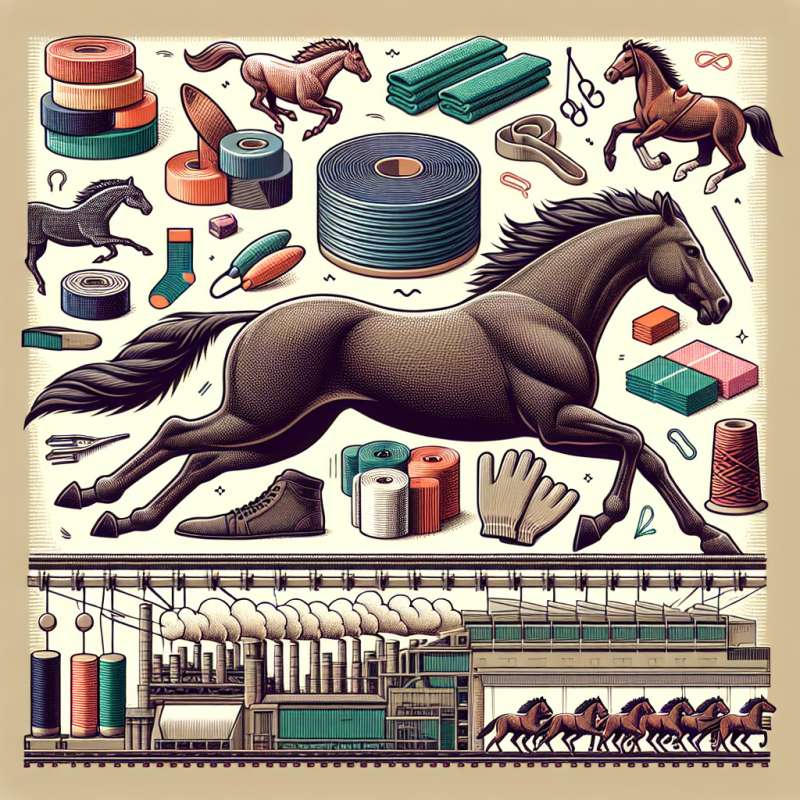

人造纖維是一種由人工合成或半合成原料製成的纖維,廣泛應用於紡紗製程中。在紡製過程中,人造纖維可以被加工成各種不同的紗線,用於製造各種紡織品,如衣服、窗簾、地毯等。

人造纖維的製程包括將原料溶解或熔化,然後將其通過紡紗機器,將纖維拉伸成細長的紗線。這些紗線可以進一步編織或織造成不同的紡織品。人造纖維具有許多優點,如柔軟、耐磨、易保養等,因此在紡織業中得到廣泛應用。

在紡紗製程中,人造纖維的選擇對最終產品的質量和性能起著至關重要的作用。不同類型的人造纖維具有不同的特性,如聚酯纖維具有良好的耐磨性和耐皺性,而聚酰胺纖維則具有優異的彈性和吸濕性。

總的來說,人造纖維在紡紗製程中的應用為紡織業帶來了許多便利和優勢,同時也為消費者提供了更多選擇。隨著技術的不斷進步,人造纖維的應用範圍將會不斷擴大,為紡織業的發展帶來新的契機。

Keywords: synthetic fibers, spinning, manufacturing

Title: Exploring the Application of Synthetic Fibers in the Spinning Process

Article: Synthetic fibers are fibers made from synthetic or semi-synthetic materials, widely used in the spinning process. During the manufacturing process, synthetic fibers can be processed into various yarns used to produce a variety of textile products such as clothing, curtains, carpets, and more.

The manufacturing process of synthetic fibers involves dissolving or melting the raw materials, then passing them through spinning machines to stretch the fibers into long yarns. These yarns can be further woven or knitted into different textile products. Synthetic fibers have many advantages such as softness, durability, and easy maintenance, making them widely used in the textile industry.

The choice of synthetic fibers in the spinning process plays a crucial role in the quality and performance of the final products. Different types of synthetic fibers have different characteristics, for example, polyester fibers have good abrasion resistance and wrinkle resistance, while polyamide fibers have excellent elasticity and moisture absorption.

In conclusion, the application of synthetic fibers in the spinning process has brought many conveniences and advantages to the textile industry, providing consumers with more choices. With the continuous advancement of technology, the application of synthetic fibers will continue to expand, bringing new opportunities for the development of the textile industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)