近年來,隨著科技的不斷發展和研發技術的提升,尼龍作為一種重要的人造纖維紡紗紡製材料,得到了廣泛應用。為了提高生產效率和產品質量,許多生產企業紛紛引進先進的機器設備進行生產。

未來,隨著研發技術的進步,我們將看到更多創新技術的應用在尼龍生產中。例如,通過機器學習和人工智能技術的應用,可以提高生產過程中的效率和精度,進而降低生產成本。這將使尼龍產品更加具有競爭力,並且能夠滿足消費者對高品質產品的需求。

此外,為了提高產品的可持續性,未來尼龍生產將更加注重環保。通過研發生產過程中減少對環境的影響的技術,例如開發可循環再用的尼龍原料,可以讓尼龍產品更加環保,符合現代社會對可持續發展的要求。

綜上所述,未來尼龍生產將會朝著更加智能化、環保化和可持續化的方向發展,這將為尼龍產業帶來更多機遇和挑戰。

Keywords: R&D, machines, nylon

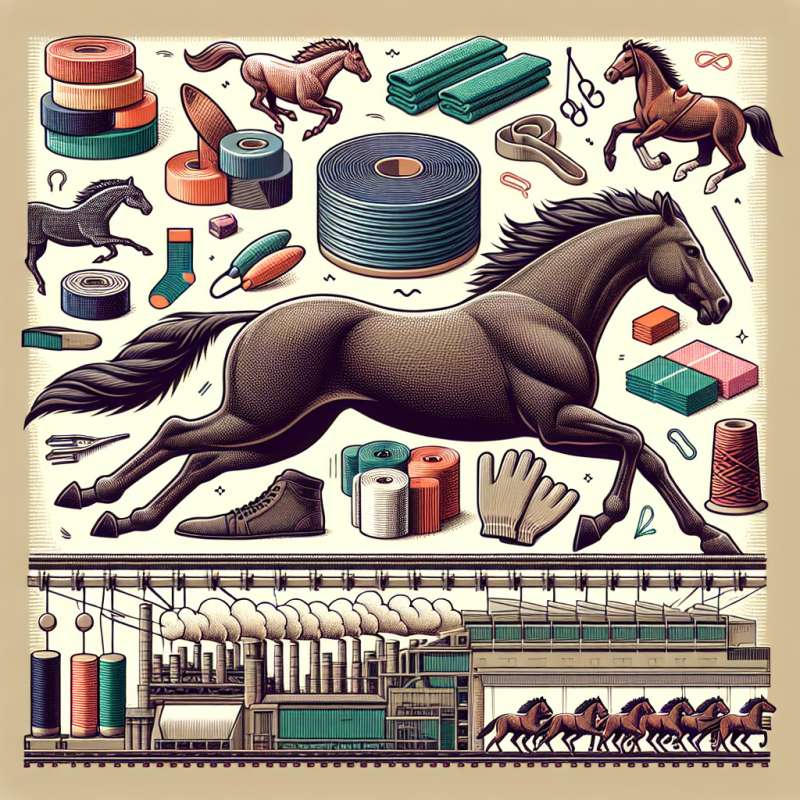

Title: Future Trends in Nylon Production

Article: In recent years, with the continuous development of technology and advances in research and development, nylon, as an important material for synthetic fiber spinning, has been widely used. In order to improve production efficiency and product quality, many manufacturing companies have introduced advanced machinery for production.

In the future, with advancements in research and development, we will see more innovative technologies applied in nylon production. For example, the application of machine learning and artificial intelligence technology can improve efficiency and accuracy in the production process, thereby reducing production costs. This will make nylon products more competitive and meet consumer demand for high-quality products.

Furthermore, in order to enhance product sustainability, future nylon production will focus more on environmental protection. By developing technologies that reduce environmental impact during production, such as creating recyclable nylon materials, nylon products can become more environmentally friendly, meeting the modern society's demand for sustainable development.

In conclusion, the future of nylon production will move towards greater intelligence, environmental friendliness, and sustainability, bringing more opportunities and challenges to the nylon industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)