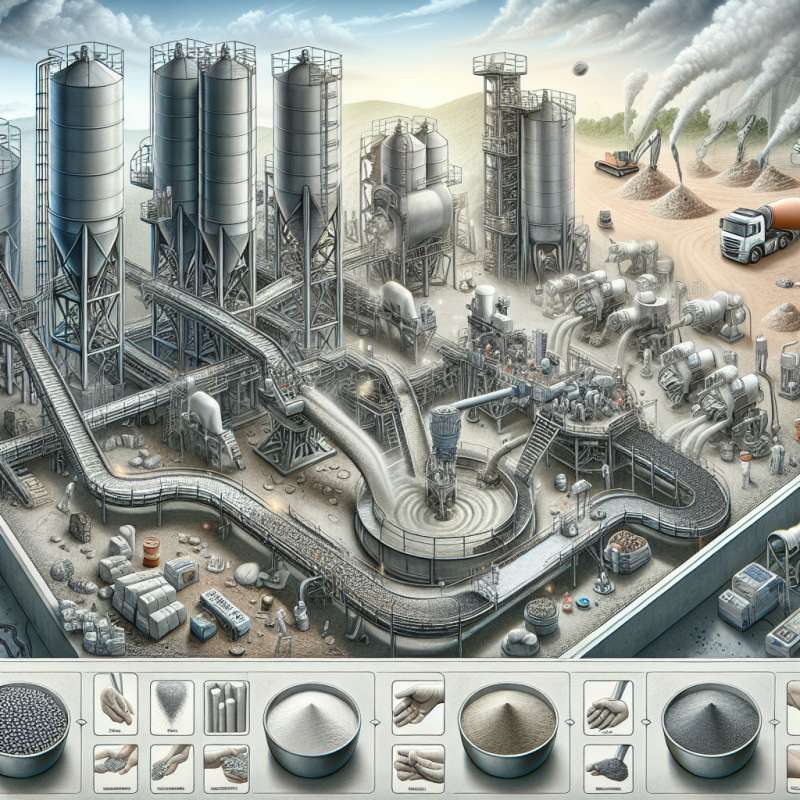

預拌混凝土是利用預先混合好的原料,在生產工藝中進行攪拌、密實而製成的混凝土產品。製造預拌混凝土需要嚴格遵循標準,以確保產品品質的一致性和可靠性。生產過程中,原料如水泥、硅酸鹽、砂、石子等按照混凝土配方比例進行添加,並根據品質控制要求進行測試和調整。

在混凝土生產過程中,設備如傳送帶、攪拌機等起著至關重要的作用。生產工藝的一個關鍵步驟是將各種原料添加進攪拌機中,通過攪拌和密實等過程,使集料均勻分佈,最終形成均勻的混凝土組成。混凝土特性的優劣取決於原料的品質和生產工藝的控制。

在施工現場,混凝土測試是確保混凝土強度和耐久性的關鍵。透過對混凝土強度的實驗測試,可以了解混凝土的承載能力和適用範圍。同時,施工質量也需要在施工環境中不斷進行監控和調整,以確保施工品質符合標準要求。

關鍵字:precast concrete, production process, standards

Title: Precast Concrete Production and Standards

Article: Precast concrete is a type of concrete produced by mixing raw materials in advance and then compacting the mixture using specific production processes. The manufacturing of precast concrete must adhere to strict standards to ensure consistent and reliable product quality. During the production process, materials such as cement, silicates, sand, gravel, etc., are added according to the concrete mix ratio and undergo testing and adjustment according to quality control requirements.

Equipment such as conveyors and mixers play a crucial role in the precast concrete production process. A key step in the production process is adding various materials into the mixer and ensuring the uniform distribution of aggregates through mixing and compacting processes to achieve a uniform concrete composition. The quality of concrete properties depends on the quality of raw materials and the control of the production process.

Concrete testing at the construction site is essential to ensure concrete strength and durability. Through experimental testing of concrete strength, the load-bearing capacity and application range of concrete can be determined. Simultaneously, construction quality needs to be continuously monitored and adjusted in the construction environment to ensure compliance with standard requirements.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)