混凝土製造是水泥產業中至關重要的一環,它涉及原料的選擇、混凝土配方的設計、生產工藝的控制以及品質控制等多個環節。在混凝土製造過程中,原料包括水泥、硅酸鹽、砂、石子等,這些原料的質量直接影響混凝土的特性和品質。為了確保混凝土的強度和耐久性,製造商需要嚴格控制原料的質量,並根據混凝土配方進行生產。

在混凝土製造過程中,施工現場和施工環境也對混凝土的品質產生影響。施工現場的環境條件需要符合標準,並保持清潔和整潔,以確保混凝土的製造過程不受污染。此外,混凝土測試也是確保混凝土品質的重要手段,包括強度測試、耐久性測試等。

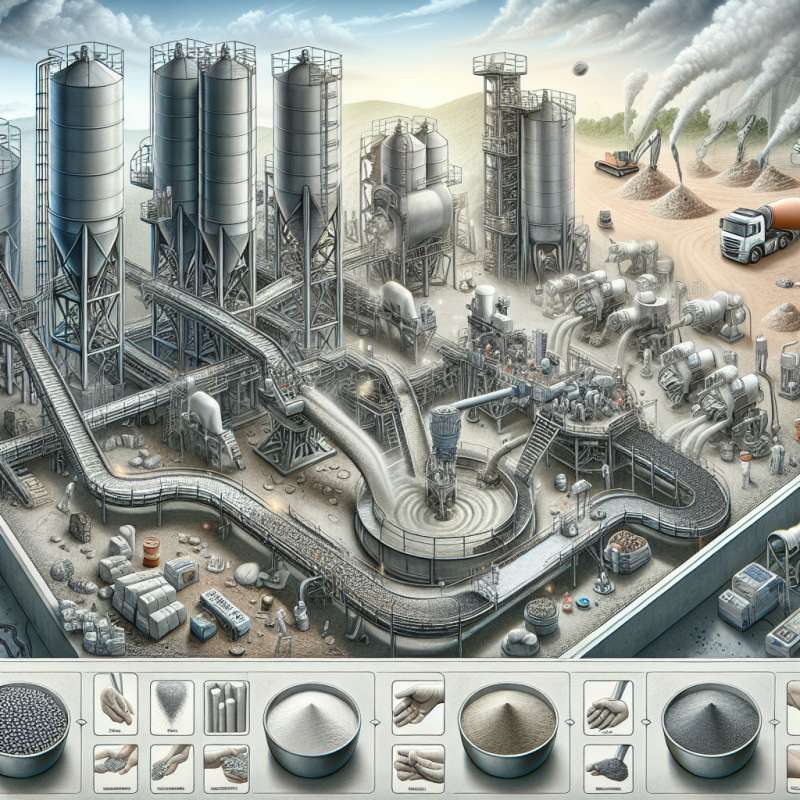

為了提高混凝土的施工質量,製造商需要採用先進的生產工藝和品質控制技術。這包括使用先進的設備如攪拌機、傳送帶等,並採用擁壓技術、分散纖維等抗裂措施,以確保混凝土的密實性和強度。同時,製造商還需要注意防水、減水劑、外加劑等添加劑的使用,以提高混凝土的流動性和早強性。

總的來說,混凝土製造和水泥產業的品質控制是確保混凝土產品質量的關鍵。製造商需要不斷改進生產工藝和施工技術,以確保混凝土產品符合標準,並滿足工程的需求。

Translation:

Keywords: Concrete manufacturing, Cement industry, Quality control

Title: Quality Control in Concrete Manufacturing and Cement Industry

Article: Concrete manufacturing is a crucial part of the cement industry, involving the selection of raw materials, design of concrete mixtures, control of production processes, and quality control. In the process of concrete manufacturing, raw materials include cement, silicates, sand, gravel, etc., and the quality of these materials directly affects the characteristics and quality of concrete. To ensure the strength and durability of concrete, manufacturers need to strictly control the quality of raw materials and produce according to the concrete mix design.

During the concrete manufacturing process, the construction site and environment also impact the quality of concrete. The environmental conditions of the construction site need to meet standards and maintain cleanliness to ensure that the concrete manufacturing process is not contaminated. Additionally, concrete testing is an important means to ensure concrete quality, including strength testing, durability testing, etc.

To improve the construction quality of concrete, manufacturers need to adopt advanced production processes and quality control technologies. This includes using advanced equipment such as mixers, conveyors, and employing techniques like compaction and fiber dispersion to prevent cracking and ensure concrete density and strength. Manufacturers also need to pay attention to the use of additives such as waterproofing agents, water reducers, admixtures to enhance concrete flowability and early strength.

In conclusion, quality control in concrete manufacturing and the cement industry is crucial to ensuring the quality of concrete products. Manufacturers need to continuously improve production processes and construction techniques to ensure that concrete products meet standards and meet the requirements of engineering projects.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)