隨著科技的進步和製造業的發展,越來越多的企業開始導入CNC(Computer Numerical Control)技術和NC(Numeric Control)技術進行精密加工。這些技術的應用不僅可以提高生產效率,還可以提高產品的精度和質量。

在成衣機械設備製造領域,CNC和NC技術被廣泛應用於製造零件和組件。通過使用這些技術,製造商可以實現更精確的加工,提高產品的一致性和品質。此外,電動技術的發展也為成衣機械設備製造帶來了更多的可能性,提高了設備的效率和耐用性。

隨著產業的不斷發展,精密加工技術在成衣機械設備製造中的應用將會愈發重要。未來,我們可以預見更多的機械設備將搭載CNC和NC控制系統,進一步提高生產能力和產品質量。同時,電動技術的進步也將帶來更高效、更節能的生產方式,推動成衣機械設備製造行業向更加智能化和自動化方向發展。

Keywords: CNC, electric, precision, NC, garment machinery and equipment manufacturing

Title: The Application and Prospects of CNC Machining Technology in Garment Machinery and Equipment Manufacturing

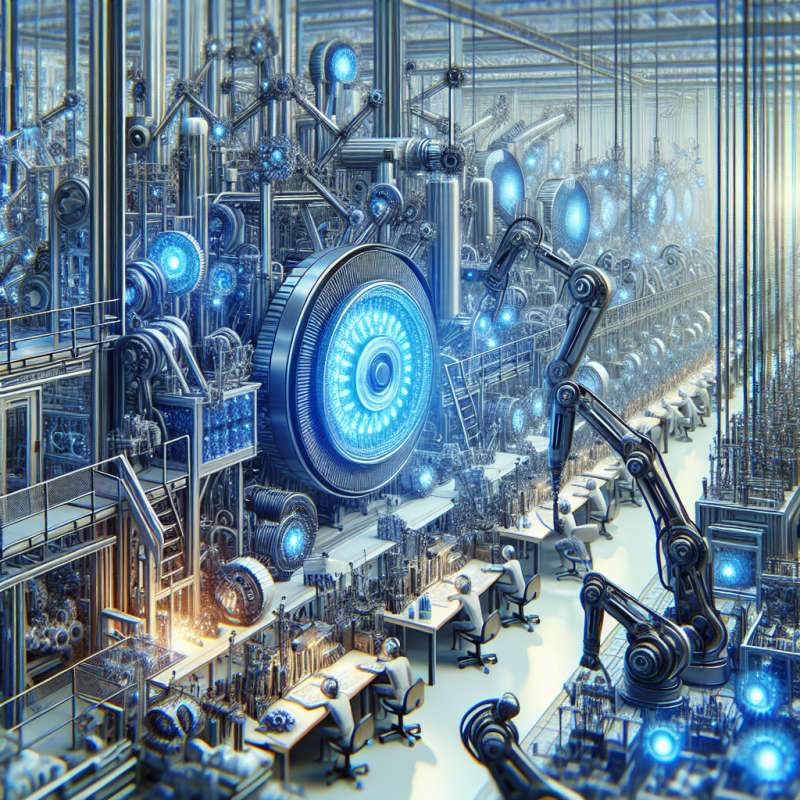

Article: With the advancement of technology and the development of the manufacturing industry, more and more companies are adopting CNC (Computer Numerical Control) and NC (Numeric Control) technology for precision machining. The application of these technologies not only improves production efficiency, but also enhances the accuracy and quality of products.

In the field of garment machinery and equipment manufacturing, CNC and NC technology are widely used in the production of parts and components. By utilizing these technologies, manufacturers can achieve more precise machining, enhancing the consistency and quality of products. Furthermore, the development of electric technology brings more possibilities to garment machinery and equipment manufacturing, improving the efficiency and durability of equipment.

As the industry continues to evolve, the application of precision machining technology in garment machinery and equipment manufacturing will become increasingly important. In the future, we can expect to see more machinery and equipment equipped with CNC and NC control systems, further enhancing production capabilities and product quality. Meanwhile, the advancement of electric technology will bring a more efficient and energy-saving production method, driving the garment machinery and equipment manufacturing industry towards a more intelligent and automated direction.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)