近年來,成衣機械設備製造市場的需求呈現持續增長的趨勢。這其中,CNC加工、雷射雕刻和縫紉機零件的應用越來越受到廣泛關注。

CNC加工技術的發展使得成衣機械設備的製造更加精密和高效。通過CNC加工,切斷刀板和其他零件的製造可以實現高度自動化和精準度,大大提高了生產效率和品質。

此外,雷射雕刻技術也為成衣機械設備的製造帶來了新的可能性。雷射雕刻可以實現對不鏽鋼等各種材料的精細加工和標記,使得產品更具個性化和美觀性。

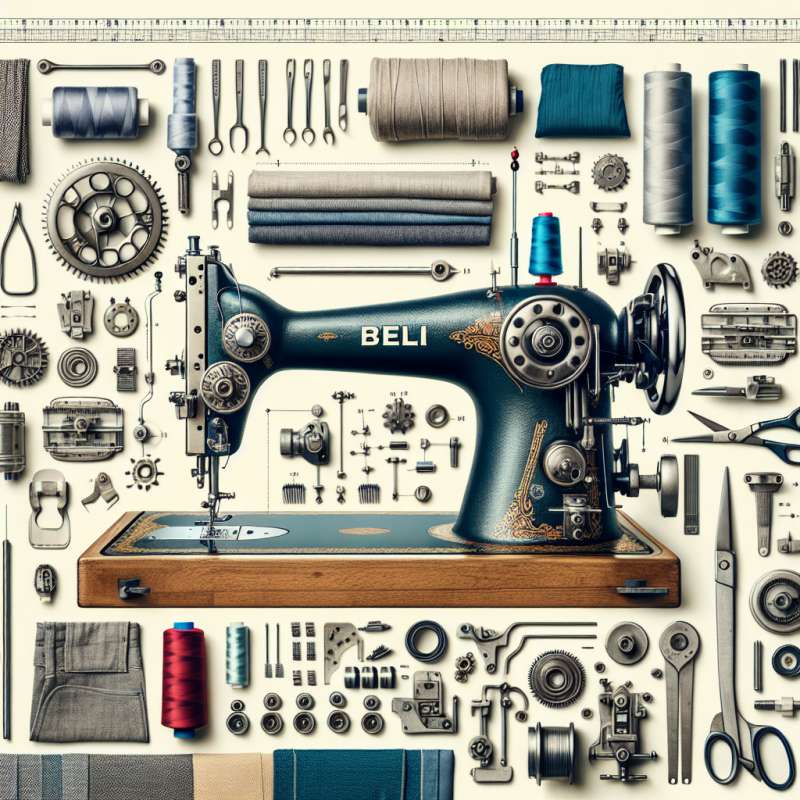

在成衣機械設備的製造過程中,縫紉機零件的加工也是至關重要的一環。精密的縫紉機零件可以確保整個設備運行順暢和穩定,滿足市場對高品質成衣的需求。

隨著紡織及成衣機械批發市場的持續擴張,對於高品質、高效率的成衣機械設備需求不斷增加。因此,CNC加工、雷射雕刻和縫紉機零件的應用將會在未來持續受到重視和推崇。

English:

Keywords: CNC machining, laser engraving, sewing machine parts, clothing machinery manufacturing, market demand growth

Title: The Application of CNC Machining in the Clothing Machinery Manufacturing Market

Article: In recent years, the demand in the market for clothing machinery manufacturing has been steadily increasing. Among them, the applications of CNC machining, laser engraving, and sewing machine parts have been gaining widespread attention.

The development of CNC machining technology has made the manufacturing of clothing machinery equipment more precise and efficient. Through CNC machining, the production of cutting knife plates and other parts can achieve high levels of automation and precision, greatly improving production efficiency and quality.

Furthermore, laser engraving technology has brought new possibilities to the manufacturing of clothing machinery equipment. Laser engraving can achieve fine processing and marking on various materials such as stainless steel, making the products more personalized and aesthetically pleasing.

In the manufacturing process of clothing machinery equipment, the machining of sewing machine parts is also a crucial aspect. Precise sewing machine parts can ensure the smooth and stable operation of the entire equipment, meeting the market demand for high-quality clothing.

With the continuous expansion of the wholesale market for textile and clothing machinery, the demand for high-quality, high-efficiency clothing machinery equipment continues to increase. Therefore, the application of CNC machining, laser engraving, and sewing machine parts will continue to be valued and promoted in the future.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)