在LED產業迅速發展的背景下,顯示技術也逐漸受到關注。其中,LED膠材作為一種重要的材料,在提升顯示性能方面起著關鍵作用。本文將探討折射率、穿透率與LED膠材之間的關聯,以及未來發展趨勢。

折射率是衡量材料光學性能的重要指標之一。在LED顯示技術中,折射率的高低直接影響到光的折射角度,進而影響到顯示品質。因此,開發具有較低折射率的LED膠材成為了一個重要的研究方向。透明度的提升,使得穿透率大幅提高,進而提升顯示效果。

此外,LED膠材的IMD硬膜技術也是近年來的重要發展方向之一。IMD(In-Mold Decoration)技術是一種將彩色圖案融合到塑膠材料表面的技術。通過IMD硬膜技術,LED膠材的視覺效果得到了進一步的提升,同時也增加了產品的抗刮擦性和抗紫外線能力。

在LED膠材的製備過程中,紫外線硬化是一個重要的技術。紫外線硬化能夠提高材料的硬度和耐磨性,同時也可以實現快速固化,提高生產效率。這使得紫外線硬化成為了製造業界廣泛應用的技術。

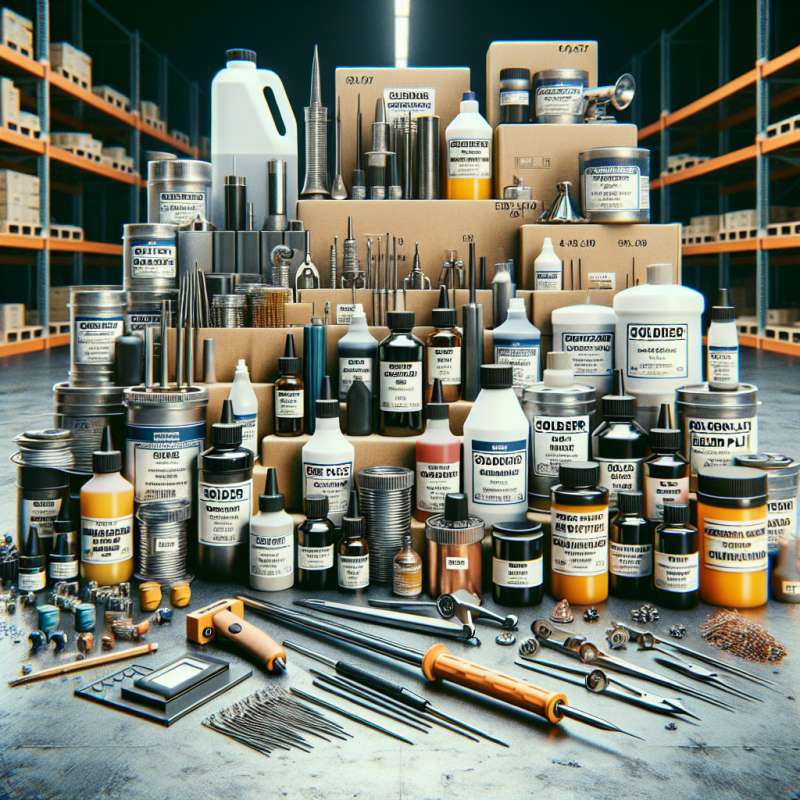

除了LED膠材的研發和製造,PCB油墨、工業助劑製造、塗料製造以及其他化學原材料及其製品的批發也是相關產業鏈中不可或缺的環節。這些行業提供了LED膠材製造過程中所需的關鍵化學原材料和支援設備。

而在LED膠材製品的連接製造,電子連接器(線)製造是不可或缺的一部分。電子連接器(線)的生產技術和品質直接影響到整體產品的可靠性和性能。因此,未來的發展趨勢將會更加注重電子連接器(線)的精確和可持續性。

總的來說,LED膠材的未來發展趨勢將會聚焦於折射率和穿透率的提高、IMD硬膜技術的應用、紫外線硬化技術的改進以及與其他相關領域的合作與協同創新。這些方向的不斷突破和創新,將會進一步推動LED膠材在顯示技術領域的應用與發展。

關鍵字: Refractive index, Transmittance, LED adhesive material, IMD film, UV curing, PCB ink, Industrial additive manufacturing, Coating manufacturing, Wholesale of other chemical raw materials and products, Electronic connectors (wires) manufacturing

標題: The Future Development Trend of LED Adhesive Materials

With the rapid development of the LED industry, display technologies have also gained increasing attention. Among them, LED adhesive materials play a critical role in enhancing display performance. This article explores the relationship between refractive index, transmittance, and LED adhesive materials, as well as their future development trends.

Refractive index is an important indicator for measuring the optical performance of materials. In LED display technology, the refractive index directly affects the angle of light refraction, thereby impacting display quality. Therefore, the development of LED adhesive materials with lower refractive index has become an important research direction. The improvement in transparency has led to a significant increase in transmittance, thereby enhancing display effects.

In addition, the IMD film technology of LED adhesive materials is also an important development direction in recent years. IMD (In-Mold Decoration) technology is a technique that integrates colorful patterns into the surface of plastic materials. Through IMD film technology, the visual effect of LED adhesive materials has been further enhanced, while also increasing scratch resistance and UV protection.

UV curing is an important technique in the preparation process of LED adhesive materials. UV curing can increase material hardness and wear resistance, while also achieving rapid curing and improving production efficiency. This has made UV curing a widely adopted technology in the manufacturing industry.

In addition to the research and manufacturing of LED adhesive materials, PCB ink, industrial additive manufacturing, coating manufacturing, and wholesale of other chemical raw materials and products are also indispensable aspects of the related industry chain. These industries provide the critical chemical raw materials and support equipment required for the manufacturing process of LED adhesive materials.

Furthermore, electronic connectors (wires) manufacturing is an essential part of the production of LED adhesive material products. The production technology and quality of electronic connectors (wires) directly impact the overall product reliability and performance. Therefore, future development trends will focus more on the precision and sustainability of electronic connectors (wires).

In summary, the future development trend of LED adhesive materials will focus on improving refractive index and transmittance, applying IMD film technology, enhancing UV curing technology, and promoting collaboration and synergies with other related fields. Continuous breakthroughs and innovation in these directions will further drive the application and development of LED adhesive materials in the display technology field.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)