關鍵字:流量傳訊器、液位計、計量及計數器製造

近年來,隨著物聯網的迅速發展,許多傳統的工業裝置也逐漸加入了智能化的行列。尤其是在流體控制領域,智能液位計和流量傳訊器正成為未來的發展趨勢。

流量傳訊器是一種用於測量和監控流體流量的裝置。它可以通過傳感器和連接設備將數據傳輸到計算機系統,提供快速和準確的流量信息。在工業生產過程中,流量傳訊器可以幫助企業實時監測流體的使用情況,節約資源並提高生產效率。

進一步來說,智能化的流量傳訊器可以與其他裝置進行無縫整合,實現更高程度的自動化。例如,在供應鏈管理中,智能流量傳訊器可以與物流系統和庫存管理系統相連接,實現實時的物料流轉監測和庫存管理。這樣做不僅可以減少人力成本,還可以提高生產流程的可控性。

而液位計則是用來測量容器中液體的高度的裝置。它一般由傳感器和顯示系統組成,可以提供液體的準確高度信息。液位計主要應用於工業領域的液體儲存和流程管道監控中。例如,在石油化工行業,液位計可以幫助監測油槽中的油位變化,以確保生產安全。另外,液位計也具有在醫療和食品工業中應用的潛力,可以幫助確保液體儲存和輸送的衛生標準。

除了流量傳訊器和液位計,計量及計數器製造也是未來發展的關鍵領域。計量及計數器製造業是製造各種計量和計數器的行業,如溫度計、壓力計等。隨著科技的進步,未來將會有更多創新的計量和計數器呈現在市場上。例如,隨著人們對環境保護意識的提高,環境監測計量和計數器的需求也將不斷增加。

總結而言,智能液位計、流量傳訊器和計量及計數器製造是未來工業領域的重要發展趨勢。隨著物聯網和自動化技術的發展,這些裝置將不斷提升生產效率,同時也為企業提供更多的監控和管理功能。我們可以預見,在未來的數字化時代,這些技術將成為各個行業不可或缺的關鍵工具。

關鍵字:Flow Transmitter, Liquid Level Gauge, Manufacturing of Meters and Counters

標題:Future Trends: The Emergence of Smart Liquid Level Gauges and Flow Transmitters

Keywords: Flow Transmitter, Liquid Level Gauge, Manufacturing of Meters and Counters

In recent years, with the rapid development of the Internet of Things (IoT), many traditional industrial devices have also gradually joined the ranks of smart technology. Especially in the field of fluid control, smart liquid level gauges and flow transmitters are becoming the future trend.

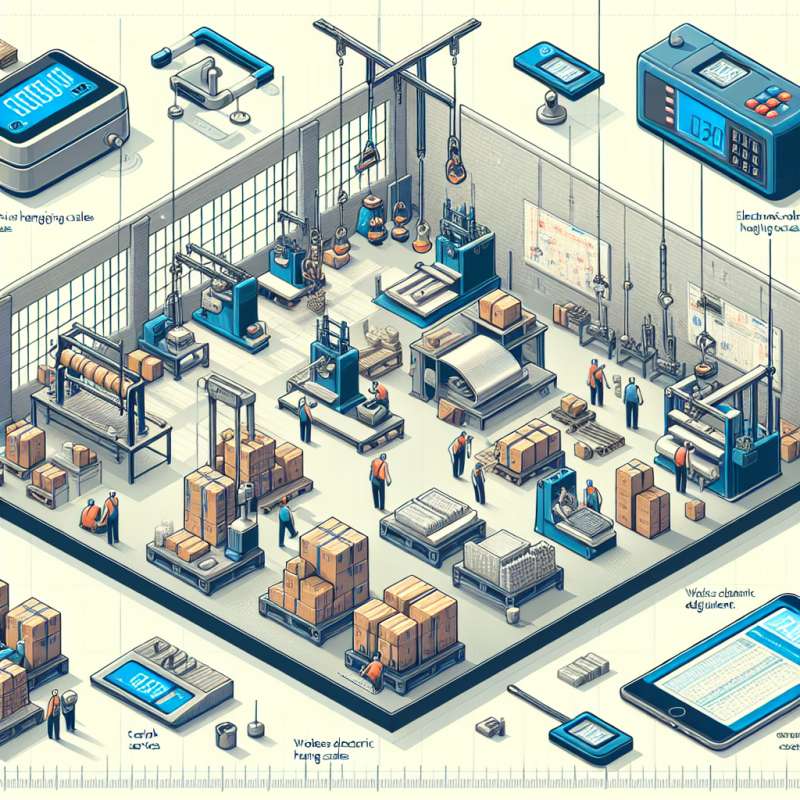

A flow transmitter is a device used to measure and monitor fluid flow. It can transmit data to a computer system through sensors and connected devices, providing fast and accurate flow information. In industrial production processes, flow transmitters can help companies monitor fluid usage in real time, saving resources and improving production efficiency.

Furthermore, intelligent flow transmitters can seamlessly integrate with other devices, achieving a higher level of automation. For example, in supply chain management, smart flow transmitters can be connected to logistics systems and inventory management systems, realizing real-time monitoring of material flow and inventory management. This not only reduces labor costs but also improves the controllability of production processes.

On the other hand, a liquid level gauge is used to measure the height of a liquid in a container. It generally consists of sensors and display systems, providing accurate height information of the liquid. Liquid level gauges are mainly used in industrial applications such as liquid storage and process pipeline monitoring. For example, in the petrochemical industry, liquid level gauges can help monitor oil level changes in tanks to ensure production safety. Additionally, liquid level gauges also have potential applications in the medical and food industries, assisting in ensuring hygienic standards for liquid storage and transportation.

In addition to flow transmitters and liquid level gauges, the manufacturing of meters and counters is also a key area of future development. The manufacturing of meters and counters is the industry that produces various measuring and counting devices, such as thermometers and pressure gauges. With technological advancements, there will be more innovative meters and counters in the market in the future. For example, as people's awareness of environmental protection increases, the demand for environmental monitoring meters and counters will also continue to grow.

In conclusion, smart liquid level gauges, flow transmitters, and the manufacturing of meters and counters are important development trends in the future industrial field. With the development of the Internet of Things and automation technology, these devices will continuously improve production efficiency while providing businesses with more monitoring and management capabilities. We can foresee that in the future digital age, these technologies will become indispensable tools in various industries.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)