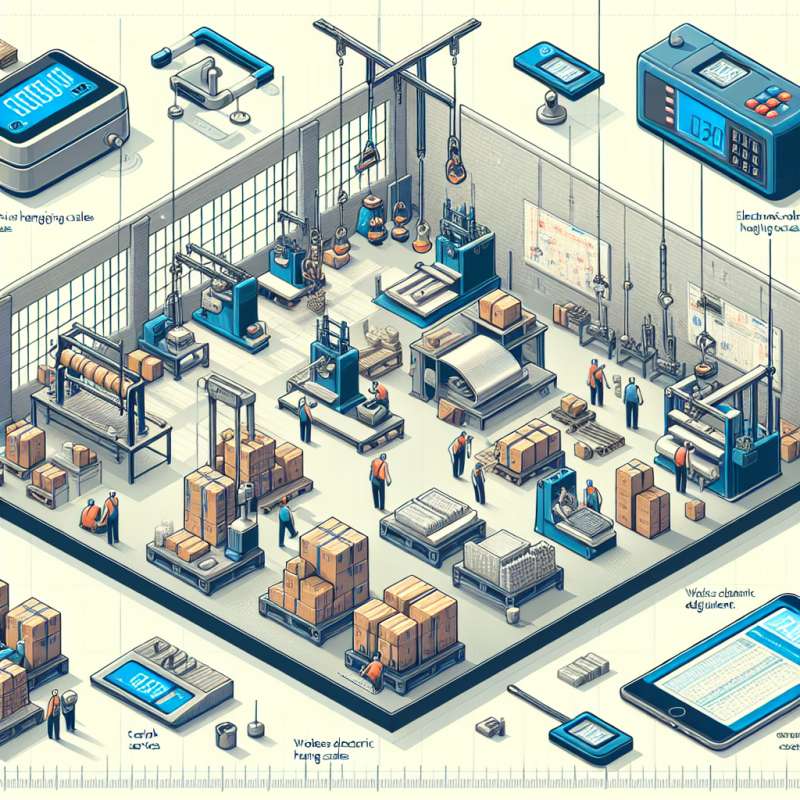

近年來,計量及計數器製造領域正在經歷著重要的轉變。隨著科技的進步,電子測量、數位化和智慧化已成為這個行業的未來趨勢。在這篇文章中,我們將探討這些趨勢如何重塑計量及計數器製造領域。

隨著現代科技的快速發展,電子測量已成為計量及計數器製造領域的重要組成部分。傳統的機械式測量儀器逐漸被先進的電子測量儀器所取代。這些電子測量儀器可以提供更高的準確性和更多的功能,並且可以輕鬆地收集和分析測量數據。例如,電流表、電壓表和頻率計都已經進行了數位化,使得使用者可以更方便地讀取和記錄測量數據。

除了數位化,物聯網(IoT)也是計量及計數器製造領域的重要趨勢之一。物聯網的出現使得計量及計數器可以與其他設備和系統進行連接,實現更高效的監測和控制。通過將計量及計數器連接到互聯網,使用者可以通過智能手機或電腦遠程監測和控制測量數據。這種連接也為計量及計數器製造商提供了更多的商機,他們可以利用數據分析和預測算法來提供更高級的服務,例如預測保養和節能優化。

人工智慧(AI)也在計量及計數器製造領域產生了重要影響。通過運用機器學習和深度學習算法,計量及計數器可以自動學習和優化性能。例如,一些高級計量及計數器可以通過分析測量數據的模式和趨勢,提供更準確的預測和警報功能。此外,AI還可以幫助確定儀器校準和校驗的最佳時機,以確保其準確性和可靠性。

總結來說,計量及計數器製造行業正日益朝著電子測量、數位化和智慧化的方向發展。這些趨勢將帶來更準確和高效的測量解決方案,同時也將提供更多商機和服務創新的可能性。因此,企業在這個行業應該加強技術研發,並積極採納新技術和創新。只有這樣,才能在競爭激烈的市場中保持領先位置。

關鍵字: Measurement and Counter Manufacturing, Electronic measurement, Digitization, Internet of Things, Artificial Intelligence

標題: Electronic Measurement, Digitization and Intelligence: Future Trends in Measurement and Counter Manufacturing

In recent years, the field of measurement and counter manufacturing has been undergoing significant changes. With the advancement of technology, electronic measurement, digitization, and intelligence have become the future trends in this industry. In this article, we will explore how these trends reshape the field of measurement and counter manufacturing.

With the rapid development of modern technology, electronic measurement has become an integral part of measurement and counter manufacturing. Traditional mechanical measuring instruments are gradually being replaced by advanced electronic measuring instruments. These electronic measuring instruments can provide higher accuracy and more functionalities, and they can easily collect and analyze measurement data. For example, ammeters, voltmeters, and frequency meters have all been digitized, making it more convenient for users to read and record measurement data.

In addition to digitization, the Internet of Things (IoT) is also a significant trend in measurement and counter manufacturing. The emergence of the IoT enables measurement and counter devices to connect with other devices and systems, enabling more efficient monitoring and control. By connecting measurement and counter devices to the Internet, users can remotely monitor and control measurement data through smartphones or computers. This connectivity also provides more business opportunities for manufacturers, who can leverage data analytics and predictive algorithms to offer advanced services such as predictive maintenance and energy optimization.

Artificial Intelligence (AI) has also made a significant impact on the field of measurement and counter manufacturing. By applying machine learning and deep learning algorithms, measurement and counter devices can learn and optimize performance automatically. For instance, some advanced measurement and counter devices can provide more accurate predictions and alarms by analyzing patterns and trends in measurement data. Additionally, AI can help determine the optimal time for instrument calibration and validation to ensure accuracy and reliability.

In conclusion, the measurement and counter manufacturing industry is increasingly heading towards electronic measurement, digitization, and intelligence. These trends will bring more accurate and efficient measurement solutions, as well as more possibilities for service innovation and business opportunities. Therefore, businesses in this industry should strengthen their technology research and development and actively adopt new technologies and innovations. Only in this way can they maintain a leading position in a competitive market.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)