隨著科技的進步和智慧裝置的應用越來越廣泛,電子元件製造領域也持續進行創新與改革。SENSOR感測技術在現代生活中扮演著重要的角色,不論是智慧家居、醫療器械或自動化製造,都需要SENSOR來收集準確的數據。時間控制器則是可以精確控制裝置開啟與關閉的關鍵元件,使得設備運行更加高效並節省能源。

光傳送器是近年來受到關注的技術,通過光信號的傳輸,能夠在高速通訊和資料傳輸中取代傳統的電纜,提供更快、更可靠的連接方式。而旋轉開關則是在許多機械裝置中必不可少的元件,用來控制旋轉方向和速度,有效提高設備的操作效率。

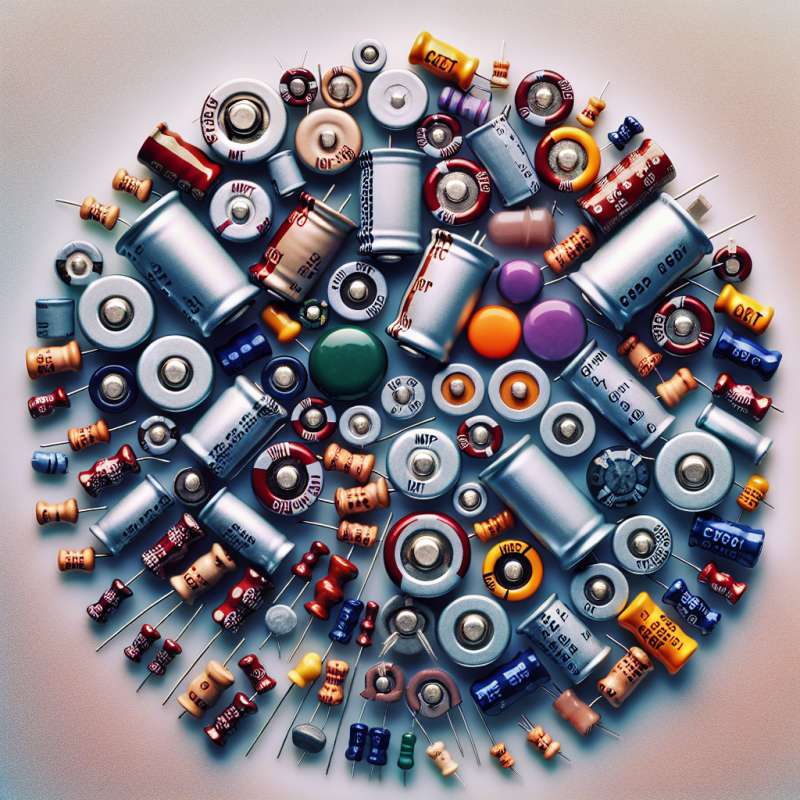

此外,被動電子元件製造也是電子製造業中不可或缺的一環。隨著科技的不斷發展,對高品質電子元件的需求也越來越高,製造商們必須不斷提升製造技術和產品品質,以滿足市場的需求。

隨著智慧科技的普及和應用範圍的擴大,未來電子元件製造將朝向更精密、更智能化的方向發展。利用先進的技術和材料,提高元件的性能和穩定性,符合綠色環保的趨勢。同時,透過數據分析和人工智能技術,實現元件生產的智慧化和自動化,提高生產效率和品質。

Keywords: SENSOR, time control, optical transmitter, rotary switch, passive electronic component manufacturing

Title: Trends and Developments in Future Electronic Component Manufacturing

Article: With the advancement of technology and the widespread use of smart devices, the field of electronic component manufacturing continues to innovate and reform. SENSOR technology plays a crucial role in modern life, whether it's smart homes, medical devices, or automation, all rely on sensors to collect accurate data. Time controllers are key components that can precisely control the on/off operation of devices, making equipment operation more efficient and energy-saving.

Optical transmitters are a technology that has garnered attention in recent years. By transmitting optical signals, they can replace traditional cables in high-speed communication and data transmission, providing a faster and more reliable connection method. Rotary switches are essential components in many mechanical devices, used to control rotation direction and speed, effectively improving operational efficiency.

In addition, the manufacturing of passive electronic components is also an indispensable part of the electronics manufacturing industry. With the continuous development of technology, the demand for high-quality electronic components is increasing, and manufacturers must continuously improve manufacturing technology and product quality to meet market demands.

With the prevalence and expansion of smart technology, the future of electronic component manufacturing will move towards a more precise and intelligent direction. By utilizing advanced technology and materials to enhance component performance and stability, it aligns with the trend of green environmental protection. Additionally, through data analysis and artificial intelligence technology, the intelligent and automated production of components can be achieved, improving production efficiency and quality.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)