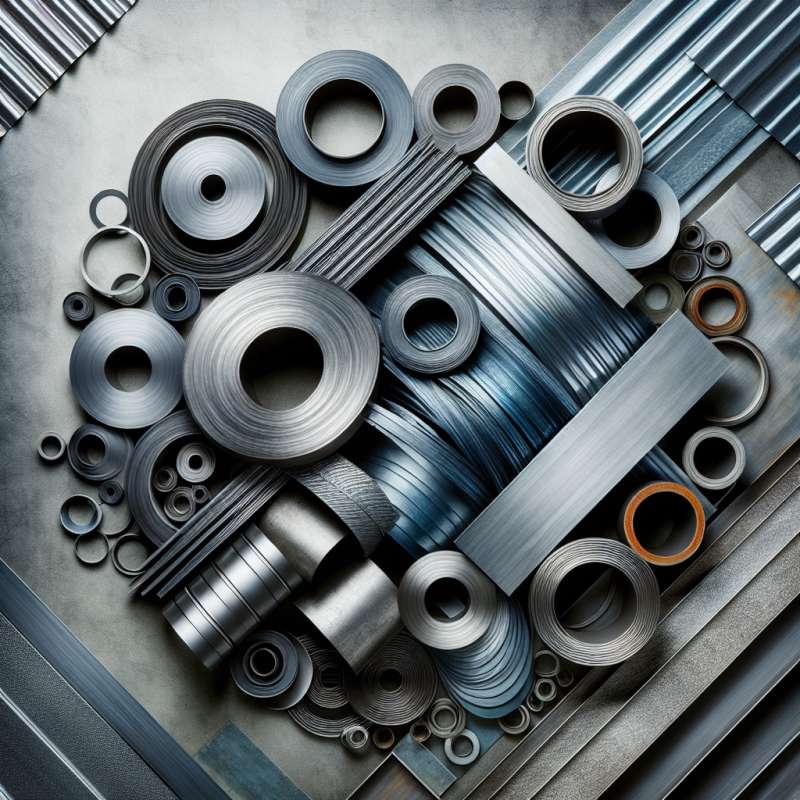

金屬製造技術一直是製造業中至關重要的一環,隨著科技的進步和需求的變化,金屬製造技術也在不斷發展。在製造金屬產品的過程中,鍛造模是一個不可或缺的工具,它能夠幫助製造出各種形狀和尺寸的金屬零件。與此同時,塑膠鋼模的應用也在逐漸增加,它可以幫助製造出複雜的金屬部件,提高生產效率和產品質量。

除了模具技術,機械零件的製造也扮演著重要的角色。機械零件的精密度和質量直接影響著最終產品的性能和品質。因此,製造機械零件的技術要求相對較高,需要使用先進的加工設備和工具,如銑床和車床。

未來,金屬製造技術將繼續朝著智能化和自動化的方向發展。隨著人工智能和機器學習技術的應用,製造商可以更精準地控制製造過程,提高生產效率和產品質量。同時,3D打印技術也將會對金屬製造技術帶來新的革命,使得製造金屬零件更加靈活和高效。

Keywords: metal, mechanical parts, forging mold, plastic steel mold

Title: Future Trends in Metal Manufacturing Technology

Article: Metal manufacturing technology has always been a crucial part of the manufacturing industry, and with the advancement of technology and changing demands, metal manufacturing technology is constantly evolving. In the process of manufacturing metal products, forging molds are indispensable tools that can help produce various shapes and sizes of metal parts. Meanwhile, the application of plastic steel molds is also increasing gradually, as it can help manufacture complex metal components, improving production efficiency and product quality.

In addition to mold technology, the production of mechanical parts also plays an important role. The precision and quality of mechanical parts directly affect the performance and quality of the final product. Therefore, the technology for manufacturing mechanical parts requires relatively high precision and quality, utilizing advanced processing equipment and tools such as milling machines and lathes.

In the future, metal manufacturing technology will continue to evolve towards intelligent and automated directions. With the application of artificial intelligence and machine learning technology, manufacturers can more precisely control the manufacturing process, improving production efficiency and product quality. Meanwhile, 3D printing technology will also bring a new revolution to metal manufacturing technology, making the manufacturing of metal parts more flexible and efficient.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)