近年來,LED與雷射技術在不鏽鋼製造領域中扮演著越來越重要的角色。LED技術被廣泛應用於不鏽鋼照明產品的製造中,其高效節能的特性使得不鏽鋼燈具更加環保和耐用。同時,雷射技術在不鏽鋼加工中也發揮著重要作用,如雷射切割和蝕刻技術能夠精準地製造出各種形狀和圖案的不鏽鋼產品。

未來,隨著電子產業的發展,LED照明產品將會更加普及,不鏽鋼作為LED燈具的主要材料之一,將會迎來更大的市場需求。同時,隨著電子產品的不斷創新,對不鏽鋼材料的要求也將不斷提高,這將促進不鏽鋼製造技術的不斷創新和提升。

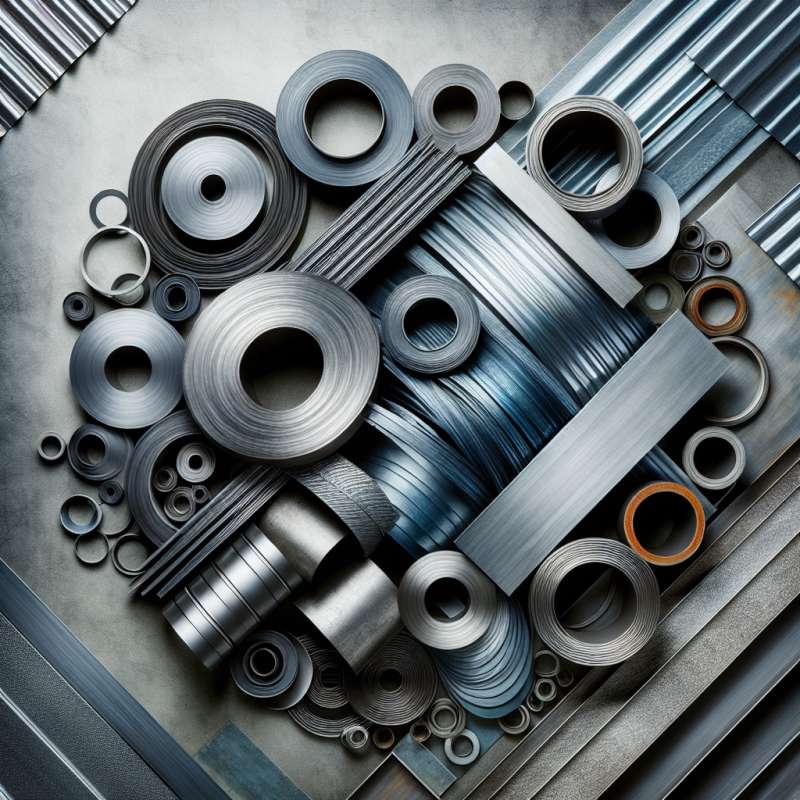

在製造過程中,鋼板製造是不可或缺的一環。鋼板製造需要使用各種治具和蒸鍍遮罩MASK等工具,以確保製造出高質量的鋼板產品。未來,隨著太陽能產業的快速發展,對鋼板的需求也將會增加,這將推動鋼板製造技術的進一步發展和完善。

關鍵字: LED, laser, stainless steel, electronics, steel plate manufacturing

Title: The Application of LED and Laser Technology in Stainless Steel Manufacturing

Article: In recent years, LED and laser technology have played an increasingly important role in the field of stainless steel manufacturing. LED technology is widely used in the production of stainless steel lighting products, with its high efficiency and energy-saving characteristics making stainless steel fixtures more environmentally friendly and durable. At the same time, laser technology also plays a crucial role in stainless steel processing, with laser cutting and etching techniques being able to precisely manufacture a variety of shapes and patterns of stainless steel products.

In the future, with the development of the electronics industry, LED lighting products will become more popular, and stainless steel as one of the main materials for LED fixtures will see a greater market demand. As electronic products continue to innovate, the requirements for stainless steel materials will also increase, driving continuous innovation and improvement in stainless steel manufacturing technology.

In the manufacturing process, steel plate manufacturing is an indispensable part. Steel plate manufacturing requires the use of various fixtures and tools such as vapor deposition masks to ensure the production of high-quality steel plate products. In the future, with the rapid development of the solar energy industry, the demand for steel plates will also increase, driving further development and improvement in steel plate manufacturing technology.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)