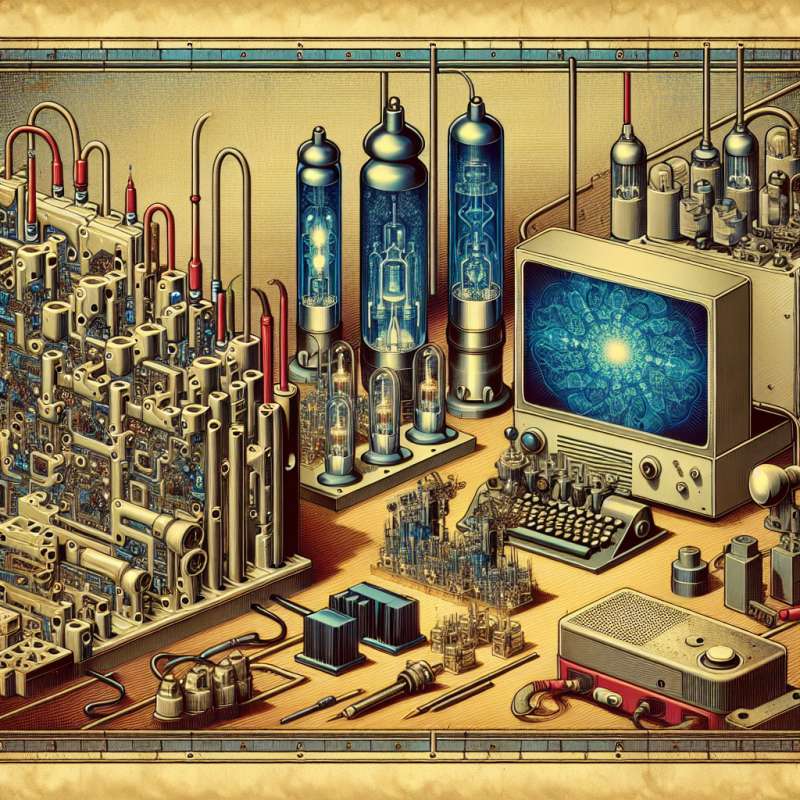

在現代科技的快速發展下,電子管製造產業正面臨著許多挑戰和未來發展的機遇。關鍵字中的模具、連接器和設計成為了影響電子管製造產業的重要因素之一。

首先,模具在電子管製造中扮演著舉足輕重的角色。隨著產品的不斷創新升級,對於具有多樣形狀和功能的模具需求也日益增加。相對應地,模具技術也不斷更新發展,以滿足製造高品質產品的需求。

此外,連接器作為將各種電子元件連接在一起的關鍵部件,在電子管製造中扮演著至關重要的角色。隨著智能產品和物聯網應用的普及,連接器的功能和性能將不斷提升,以確保高效的數據傳輸和連接。

最後,設計是電子管製造過程中不可或缺的一環。優秀的設計能夠將各項技術和元件有機結合,實現產品的功能與美感兼顧。隨著人工智能和數字化設計技術的不斷發展,設計領域將會迎來更多革新。

綜合以上三個關鍵字,可預見未來電子管製造將朝著更高效、智能化和綠色化方向發展。模具、連接器和設計將不斷優化和創新,以滿足市場對於高品質、高性能產品的需求,推動整個產業向著更美好的未來邁進。

English:

Keywords: Mold, Connector, Computer, Electronic Tube Manufacturing

Title: Future Trends in Electronic Tube Manufacturing Industry

Article: In the rapid development of modern technology, the electronic tube manufacturing industry is facing many challenges and opportunities for future development. The keywords mold, connector, and design have become important factors influencing the electronic tube manufacturing industry.

Firstly, molds play a crucial role in electronic tube manufacturing. With the continuous innovation and upgrading of products, there is an increasing demand for molds with diverse shapes and functions. Correspondingly, mold technology is constantly being updated and developed to meet the demands of manufacturing high-quality products.

In addition, connectors, as key components that connect various electronic components together, play a crucial role in electronic tube manufacturing. With the proliferation of smart products and IoT applications, the functions and performance of connectors will continue to improve to ensure efficient data transmission and connectivity.

Lastly, design is an indispensable part of the electronic tube manufacturing process. Excellent design can organically integrate various technologies and components to achieve a balance between product functionality and aesthetics. With the continuous development of artificial intelligence and digital design technology, the field of design will witness more innovations.

Considering the three keywords mentioned above, it is foreseeable that electronic tube manufacturing will evolve towards a direction of higher efficiency, intelligence, and greenization in the future. Molds, connectors, and designs will continue to be optimized and innovated to meet the market's demands for high-quality, high-performance products, driving the entire industry towards a brighter future.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)