在現代的電子製造過程中, CNC機床和切削工具扮演著至關重要的角色。透過CNC(電腦數值控制)技術,製造商能夠實現高效率、精密度和自動化的生產。同時,切削工具的質量與性能也直接影響著產品的品質和運作。

CNC機床是電子製造中不可或缺的工具之一。它通過電腦程式控制刀具和工件的運動,以完成精確的加工。例如鏜床、銑床、車床和鑽床都屬於CNC機床的一種,它們能夠在金屬基板上進行各種加工操作。

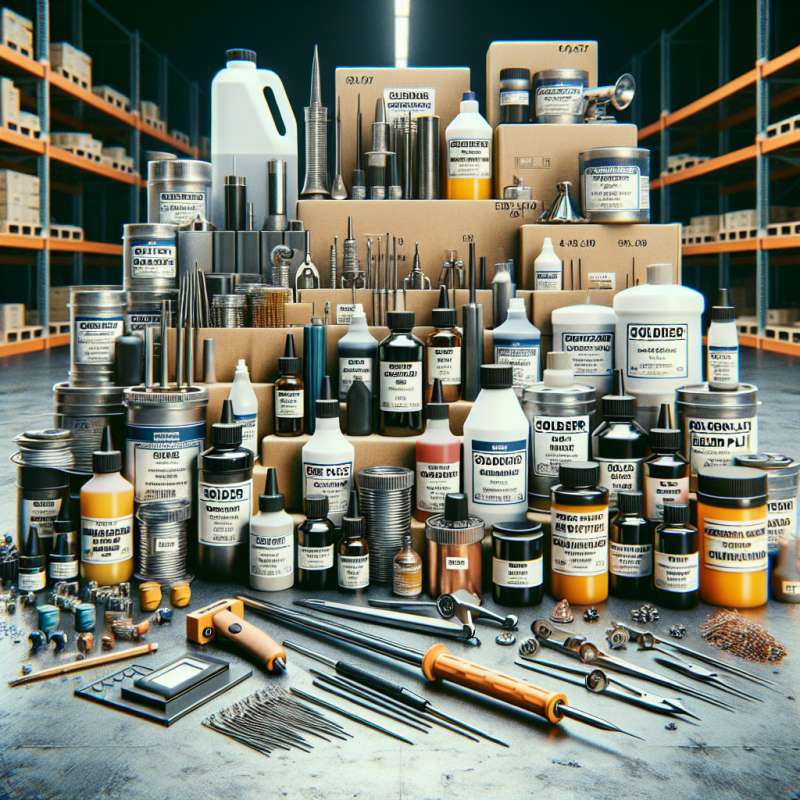

切削工具則是CNC機床中不可或缺的配件。切削工具是用於移除材料的工具,並且需要具備高耐磨性和耐用性。刀具製造過程中所選用的刀架、刀片定位,以及刀具磨損的控制都是關鍵要素。刀片的材料、切削速度、切削溫度和切屑控制等參數也會影響到切削過程的效率和效果。

在電子製造過程中,CNC機床和切削工具的結合發揮著重要作用。它們不僅能夠實現高效生產和精密加工,還能夠提高切削穩定性和金屬加工精度。自動化製造使得生產過程更加快速,同時也提高了產品的品質和一致性。

值得一提的是,CNC機床和切削工具的發展也隨著電子製造技術的進步不斷演進。新的切削材料、刀具設計和切削條件的研究,都是為了提高生產效率和製造品質。而這些技術和創新也對電子器材批發和分銷產生了重要影響。

總結而言,CNC機床和切削工具在電子製造中扮演著不可或缺的角色。這些先進的技術和工具能夠提高生產效率、精確度和自動化程度。同時,它們的發展也推動著電子器材批發和分銷行業的進步。

關鍵字: Electronic Manufacturing, CNC Machine Tools, Cutting Tools

Title: CNC Machine Tools and Cutting Tools in Electronic Manufacturing

Article: In modern electronic manufacturing processes, CNC machine tools and cutting tools play a crucial role. Through Computer Numerical Control (CNC) technology, manufacturers are able to achieve efficient, precise, and automated production. Meanwhile, the quality and performance of cutting tools directly influence product quality and operation.

CNC machine tools are essential tools in electronic manufacturing. They control the movement of tools and workpieces through computer programs to achieve precise machining. For example, machines such as boring machines, milling machines, lathes, and drilling machines are all types of CNC machine tools that can perform various operations on metal substrates.

Cutting tools are indispensable accessories in CNC machine tools. Cutting tools are used to remove material and need to have high wear resistance and durability. Factors such as tool holders, blade positioning, and control of tool wear are critical in the tool manufacturing process. Parameters such as blade material, cutting speed, cutting temperature, and chip control also affect the efficiency and effectiveness of cutting processes.

In the electronic manufacturing process, the combination of CNC machine tools and cutting tools plays a crucial role. They not only enable efficient production and precise machining but also enhance cutting stability and metal processing accuracy. Automated manufacturing ensures faster production while improving product quality and consistency.

It is worth mentioning that the development of CNC machine tools and cutting tools has evolved with the advancement of electronic manufacturing technology. New cutting materials, tool designs, and cutting conditions are researched to improve production efficiency and manufacturing quality. These technologies and innovations also have a significant impact on the wholesale and distribution of electronic equipment.

In conclusion, CNC machine tools and cutting tools play an indispensable role in electronic manufacturing. These advanced technologies and tools improve production efficiency, precision, and automation degree. Additionally, their development drives the progress of wholesale and distribution in the electronic equipment industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)