在建築行業中,預拌混凝土是一種常見的建築材料,其生產過程需要嚴格的品質控制。生產預拌混凝土的過程中,需要留意原料的質量,確保混凝土配方的準確性及生產工藝的穩定性。

預拌混凝土的主要原料包括水泥、硅酸鹽、砂、石子等。這些原料的質量將直接影響混凝土的特性及施工質量。在生產過程中,需要使用準確的設備,如攪拌機、傳送帶等,確保混凝土混合均勻並密實。

品質控制是預拌混凝土生產中至關重要的一環。通過加入溶劑、添加劑等成分,可以改善混凝土的特性,提高其強度及耐久性。同時,進行混凝土測試也是必不可少的步驟,以確保混凝土符合標準要求。

在施工現場及施工環境中,需要嚴格控制混凝土的生產過程,確保混凝土的品質。只有通過嚴格的品質控制,預拌混凝土才能在施工中發揮其最佳效果。

Keywords: Precast concrete, production, quality control, cement, concrete composition

Title: Quality Control in Precast Concrete Production

Article:

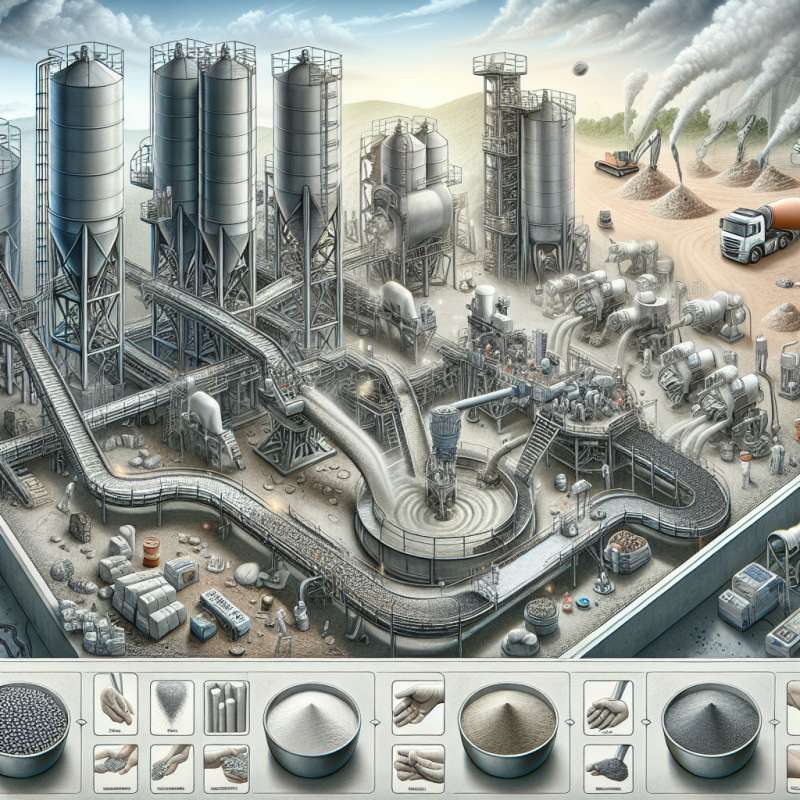

In the construction industry, precast concrete is a common building material that requires strict quality control during production. During the production of precast concrete, attention must be paid to the quality of raw materials to ensure the accuracy of the concrete mix design and the stability of the production process.

The main raw materials for precast concrete include cement, silicates, sand, stones, and more. The quality of these materials directly influences the properties of the concrete and the quality of construction. Accurate equipment such as mixers and conveyors are used in the production process to ensure that the concrete is mixed uniformly and compacted.

Quality control is a crucial part of precast concrete production. By using solvents, additives, and other components, the properties of the concrete can be improved to increase its strength and durability. Concrete tests need to be conducted regularly to ensure that the concrete meets the required standards.

Strict control is required in the production process of precast concrete at construction sites and environments to ensure the quality of the concrete. Only through rigorous quality control can precast concrete perform its best in construction.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)