在壓縮機製造領域中,N2機和冷凍乾燥機是兩個非常重要的關鍵技術。它們的發展也直接影響著整個行業的發展趨勢。

首先,N2機是指利用氮氣(N2)的壓縮和凈化技術製造的壓縮機。隨著工業發展的不斷推進,對高純度氮氣的需求也越來越大。N2機的主要功能是將氮氣從空氣中提取出來,並通過壓縮和凈化處理,以達到所需的純度和壓力條件。未來,隨著高科技行業的快速發展,對高純度氮氣的需求將進一步增加,這將推動N2機技術的不斷創新與改進。

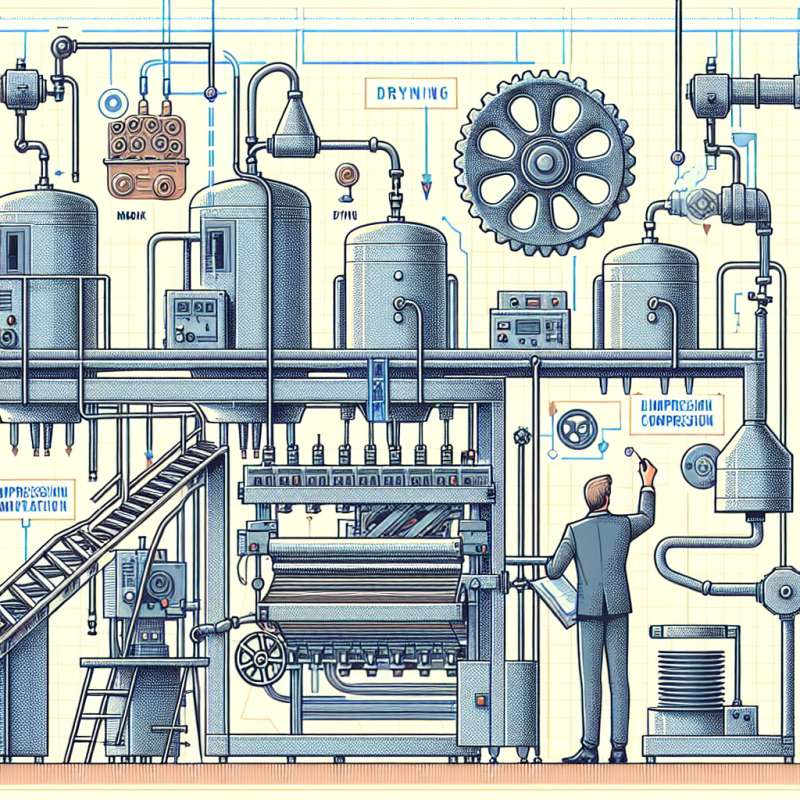

其次,冷凍乾燥機是一種將空氣中的水分凝結成水分粒子,並通過冷凍和乾燥過程將其去除的裝置。冷凍乾燥機在壓縮機製造領域中起著關鍵的作用,它可以保證壓縮機內部的氣體是乾燥的,從而減少能源消耗和延長壓縮機的使用壽命。未來,隨著環保意識的不斷提高,對於節能減排和資源回收再利用的要求也日益增加。冷凍乾燥機作為一種節能環保的設備,將成為壓縮機製造領域的重要發展方向。

最後,壓縮機製造是一個高度專業化和技術密集的行業,其發展也受到許多因素影響。隨著科技的進步和產業需求的革新,壓縮機製造領域將朝著智能化、高效能和綠色環保的方向發展。通過引入先進的控制系統和自動化技術,提高壓縮機的運行效率和可靠性。同時,注重節能減排、材料選擇和製造工藝的優化,以減少環境污染和資源浪費。這些都是未來壓縮機製造領域需要重點關注和努力實現的目標。

總的來說,N2機和冷凍乾燥機在壓縮機製造領域有著重要的地位和作用。未來的發展趨勢將以高純度氮氣和乾燥空氣供應的需求為驅動力,促進相關技術的創新和改進。同時,壓縮機製造行業將不斷追求智能化、高效能和綠色環保的發展目標,以適應不斷變化的市場需求和環境要求。

關鍵字: N2 generator, freeze dryer, compressor manufacturing

標題: The Future Development Trends of N2 Generator and Freeze Dryer in Compressor Manufacturing

In the field of compressor manufacturing, N2 generators and freeze dryers are two crucial technologies that directly impact the industry's future development trends.

Firstly, an N2 generator refers to a compressor manufactured using nitrogen (N2) compression and purification techniques. With the continuous advancement of industrial development, the demand for high-purity nitrogen gas has been increasing. The main function of an N2 generator is to extract nitrogen from the air and deliver it at the desired purity and pressure conditions through compression and purification processes. In the future, with the rapid development of high-tech industries, the demand for high-purity nitrogen gas will further increase, driving continuous innovation and improvement in N2 generator technology.

Secondly, a freeze dryer is a device that condenses moisture in the air into water particles and removes them through freezing and drying processes. Freeze dryers play a key role in compressor manufacturing by ensuring that the gas inside the compressor is dry, reducing energy consumption and extending the compressor's lifespan. In the future, as environmental awareness continues to rise, the demands for energy-saving, emission reduction, and resource recycling are increasing. As an energy-efficient and environmentally-friendly equipment, freeze dryers will become an important development direction in the field of compressor manufacturing.

Lastly, compressor manufacturing is a highly specialized and technologically intensive industry influenced by various factors. With advancements in technology and industrial innovation, compressor manufacturing will move towards intelligent, high-efficiency, and green development. Improving operational efficiency and reliability of compressors through advanced control systems and automation technology. Additionally, focusing on energy-saving, material selection, and optimizing manufacturing processes to reduce environmental pollution and resource waste. These are the key goals that the compressor manufacturing industry should focus on and strive to achieve in the future.

In conclusion, N2 generators and freeze dryers play crucial roles in the field of compressor manufacturing. Future development trends will be driven by the demand for high-purity nitrogen gas and dried air supply, promoting innovation and improvement in related technologies. Simultaneously, the compressor manufacturing industry will continuously pursue intelligent, high-efficiency, and environmentally-friendly development to adapt to changing market demands and environmental requirements.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)