金屬製造是一個複雜的過程,其中包括金屬原料熔鑄、鋼材製造、鑄造工藝、熱處理、金屬加工、金屬表面處理、塗裝、切削加工等多個步驟。在這個過程中,品質控制是至關重要的一環。

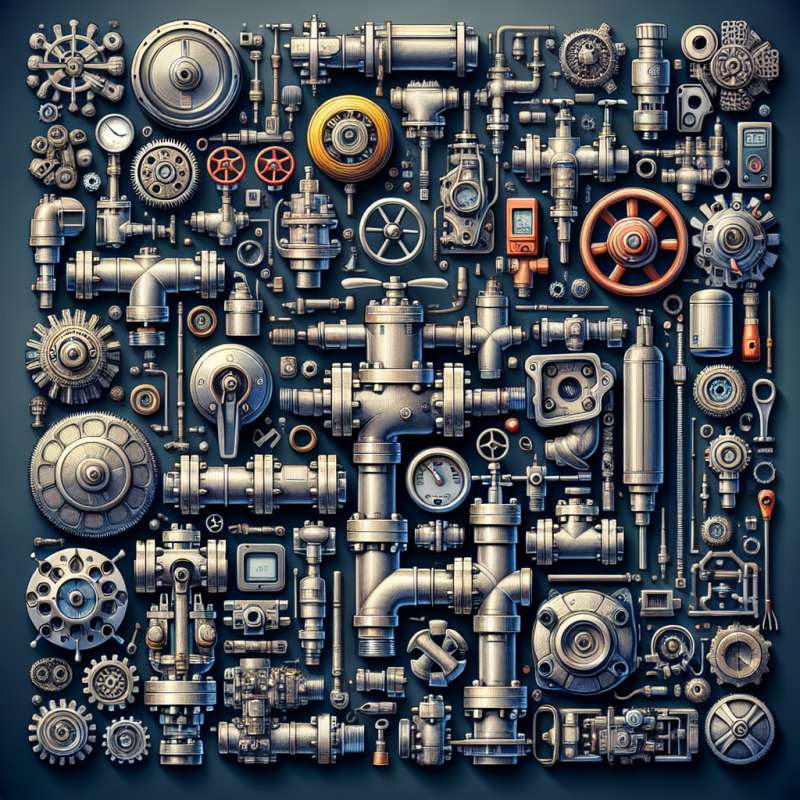

活栓制造是金屬製造流程中的一個重要環節。活栓是一種用於控制流體流動的閥門,通常應用在管道系統中。活栓制造需要嚴格的品質控制,以確保產品符合標準並具有良好的性能。品質控制包括原料檢驗、製造過程監控、成品檢測等多個方面。

在金屬製造行業中,品質控制是保證產品質量的關鍵。只有通過嚴格的品質控制,才能生產出符合客戶需求的優質產品。活栓制造公司和活閥制造公司都需要重視品質控制,以提升產品競爭力。

金屬製造行業正面臨著越來越嚴格的環保要求。為了減少對環境的影響,金屬製造公司需要採取相應的環保措施,如節能減排、循環利用資源等。只有在注重品質控制的同時,也要重視環保措施,才能實現可持續發展。

Keywords: Metal manufacturing process, Valve manufacturing, Quality control

Title: Quality Control in Metal Manufacturing Process with a Focus on Valve Manufacturing

Article: Metal manufacturing is a complex process that involves various steps such as melting metal raw materials, steel manufacturing, casting processes, heat treatment, metal processing, metal surface treatment, painting, cutting, and more. In this process, quality control is crucial.

Valve manufacturing, specifically the production of valves for controlling fluid flow in piping systems, is an important part of the metal manufacturing process. Valve manufacturing requires strict quality control to ensure products meet standards and perform well. Quality control includes raw material inspection, process monitoring, and final product testing.

In the metal manufacturing industry, quality control is key to ensuring product quality. Only through rigorous quality control can high-quality products that meet customer demands be produced. Valve manufacturing companies and valve manufacturers must prioritize quality control to enhance product competitiveness.

The metal manufacturing industry is facing increasingly stringent environmental requirements. To reduce environmental impact, metal manufacturing companies must implement environmental protection measures such as energy conservation, emissions reduction, and resource recycling. Only by focusing on both quality control and environmental protection measures can sustainable development be achieved.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)