合板是一種由組合木材經過粘合劑加工而成的板材,製造過程相當複雜。初步將木材經過切割、烘乾等工藝處理後,再進行粘合加工,需要使用特殊的機械設備和生產線。製程中技術和質量控制至關重要,必須定期進行檢測,確保合板符合相關標準。

合板廣泛應用於建築、家具製造、包裝等行業,市場需求量大。隨著人們對環保和可持續發展的重視,合板市場也越來越受到關注。合板的生產與應用需要遵守環保標準,盡量減少對環境的影響,推動綠色生產。

Keywords: Plywood, Manufacturing, Market

Title: Plywood Manufacturing and Market Application

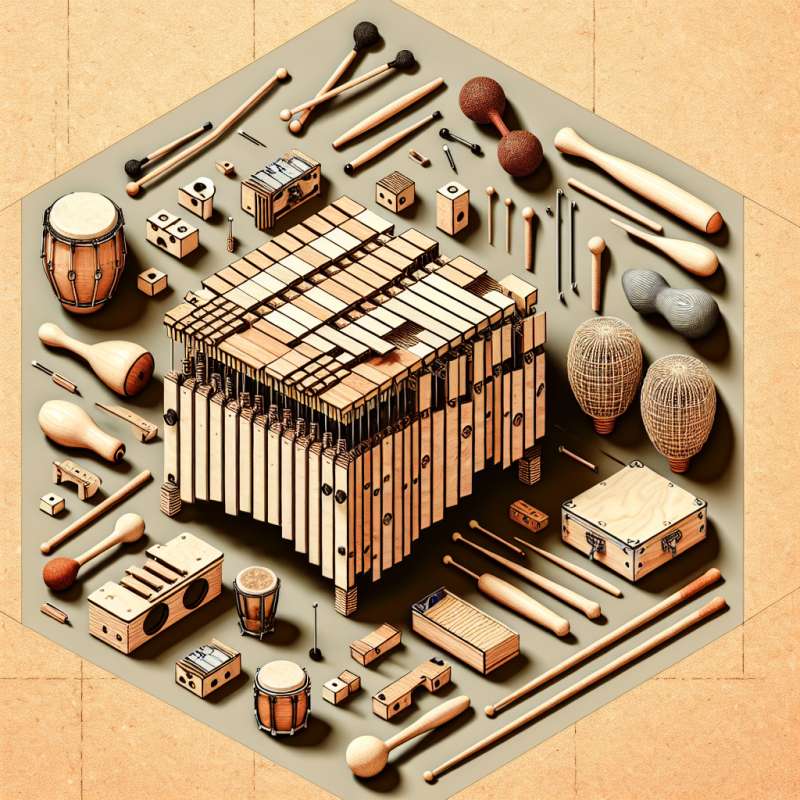

Article: Plywood is a type of board made from composite wood glued together with adhesive, and its manufacturing process is quite complex. After preliminary processing such as cutting and drying, the wood undergoes adhesive bonding, requiring special machinery and production lines. Technology and quality control are crucial in the production process, and regular testing is necessary to ensure the plywood meets relevant standards.

Plywood is widely used in industries such as construction, furniture manufacturing, and packaging, with a large market demand. With the increasing emphasis on environmental protection and sustainable development, the plywood market is gaining more attention. The production and application of plywood must comply with environmental standards to minimize the impact on the environment and promote green production.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)