合板是一種由組合木材和粘合劑製成的板材,廣泛應用於建築、家具製造和包裝行業。隨著製造技術的不斷進步,合板的生產過程也在不斷改進。

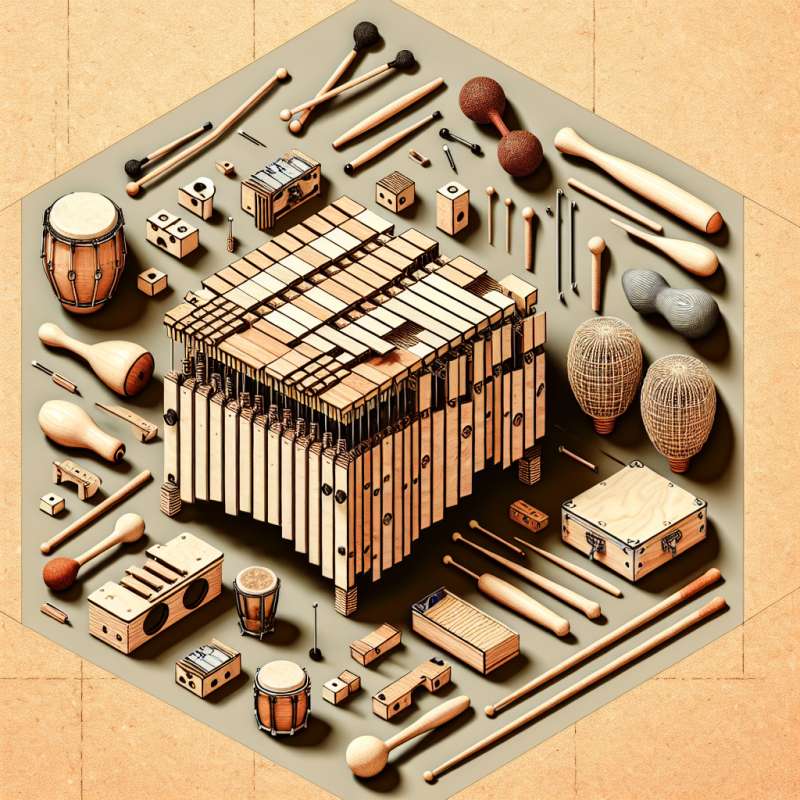

製造合板的工藝包括選材、切割、烘乾、塗膠、壓合等步驟。為了提高生產效率和產品質量,製造商們不斷引進先進的機械設備和生產線,優化製程,提升技術水平。同時,質量控制和檢測也變得越來越重要,以確保產品符合標準。

合板的應用範圍非常廣泛,不僅可以用於家具、地板、牆板等室內裝飾材料,還可以用於建築結構和包裝箱等領域。在市場上,合板因其質量穩定、價格相對較低而受到廣泛歡迎。

然而,隨著人們對環保和可持續發展的重視,製造商們也開始尋求更環保的生產方式,減少對環境的影響。一些新型的合板材料和製造技術也在不斷涌現,以滿足市場對綠色產品的需求。

Keywords: Plywood, Manufacturing, Technology

Title: Development and Application of Plywood Manufacturing Technology

Article: Plywood is a type of board made from composite wood and adhesive, widely used in construction, furniture manufacturing, and packaging industries. With the continuous advancement of manufacturing technology, the production process of plywood is also constantly improving.

The manufacturing process of plywood includes steps such as material selection, cutting, drying, gluing, pressing, etc. In order to improve production efficiency and product quality, manufacturers continuously introduce advanced machinery and production lines, optimize processes, and enhance technological capabilities. At the same time, quality control and testing have become increasingly important to ensure products meet standards.

Plywood has a wide range of applications, not only for indoor decoration materials such as furniture, flooring, wall panels, but also for building structures and packaging boxes. In the market, plywood is widely welcomed due to its stable quality and relatively low price.

However, with the increasing emphasis on environmental protection and sustainable development, manufacturers are also seeking more environmentally friendly production methods to reduce environmental impact. Some new types of plywood materials and manufacturing technologies are also emerging to meet the market demand for green products.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)