近年來,隨著科技的進步和市場需求的提升,工程塑膠製造逐漸成為製造業中的重要一環。工程塑膠作為一種機械性能優異、耐磨耐壓的材料,在各個行業中廣泛應用。工程塑膠製品的製造生產過程中,加工技術尤為關鍵。

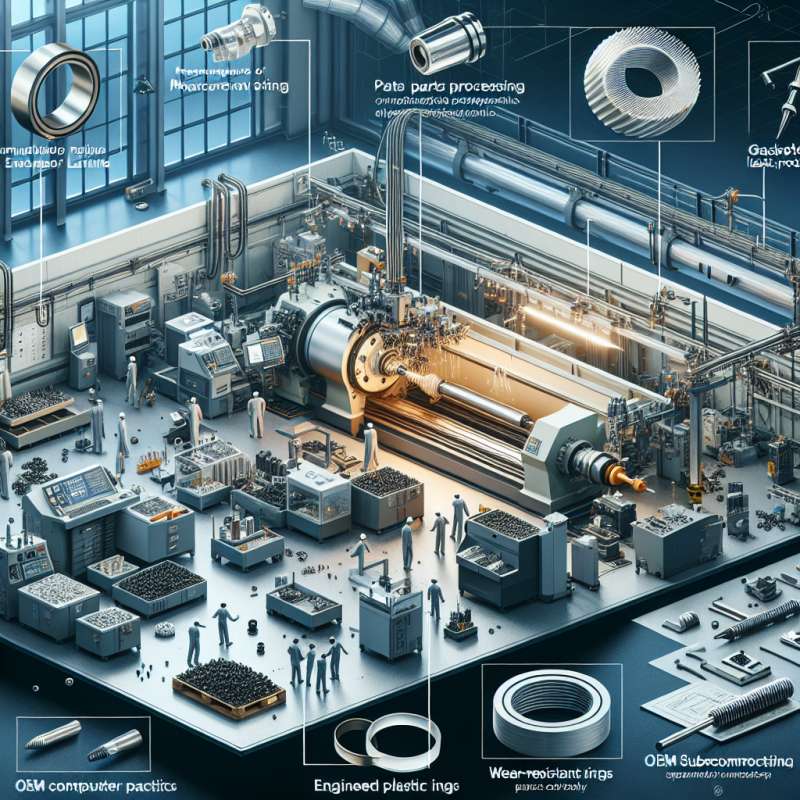

在工程塑膠製造過程中,CNC車床加工技術是一個不可或缺的工具。透過CNC車床加工,可以精密製造機械零件、塑膠板、管材等製品,並且可以實現高效、精確的生產。此外,傳統車床加工技術也在一定程度上仍然具有一定的應用價值,可以應對一些特殊形狀和要求較低的產品。

隨著市場對工程塑膠製品品質和產品設計的要求不斷提高,專業技術和OEM代工方式將更加受到重視。具有ISO認證的工廠將更受歡迎,為客戶提供高品質的產品和服務。因此,未來工程塑膠製造領域將更加注重工藝技術和品質控制。

在具體產品方面,機械底座、CNC電腦車床、耐磨環、墊片、止漏環等在工程塑膠製造中將持續扮演重要角色。這些產品在各種機械設備中具有關鍵作用,市場需求量大且穩定。

總的來說,工程塑膠製造領域將在未來持續發展壯大,加工技術和製造工藝將不斷提升,市場上對品質和精度的要求也將日益提高。

English translation:

Keywords: Manufacturing, CNC Machining, Engineering Plastics, Production, Factory

Title: Future Trends in Engineering Plastics Manufacturing

Article: In recent years, with advances in technology and increasing market demand, engineering plastics manufacturing has become an important part of the manufacturing industry. As a material with excellent mechanical properties and wear resistance, engineering plastics are widely used in various industries. The process of manufacturing engineering plastic products relies heavily on machining technology.

In the manufacturing process of engineering plastics, CNC machining technology is an indispensable tool. Through CNC machining, precise production of mechanical parts, plastic sheets, pipes, and other products can be achieved efficiently and accurately. Furthermore, traditional machining technology still has certain applications, especially for products with special shapes and lower requirements.

As market demands for quality and product design of engineering plastic products continue to rise, specialized techniques and OEM production methods will be increasingly emphasized. Factories with ISO certification will be more sought after, providing customers with high-quality products and services. Therefore, the future of engineering plastics manufacturing will focus more on process technology and quality control.

In terms of specific products, items such as machine bases, CNC computer lathes, wear rings, gaskets, and sealing rings will continue to play important roles in engineering plastics manufacturing. These products are crucial in various types of machinery, with high and stable market demand.

Overall, the field of engineering plastics manufacturing will continue to grow and expand in the future, with machining technology and manufacturing processes constantly improving, and market demands for quality and precision on the rise.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)