塑膠板是一種常見的塑料製品,廣泛應用於建築、包裝、家具等領域。在塑膠板的製造過程中,原料的選擇和品質控制至關重要。生產廠家需要確保使用的原料符合相關標準,以確保最終產品的耐用性和耐腐蝕性。

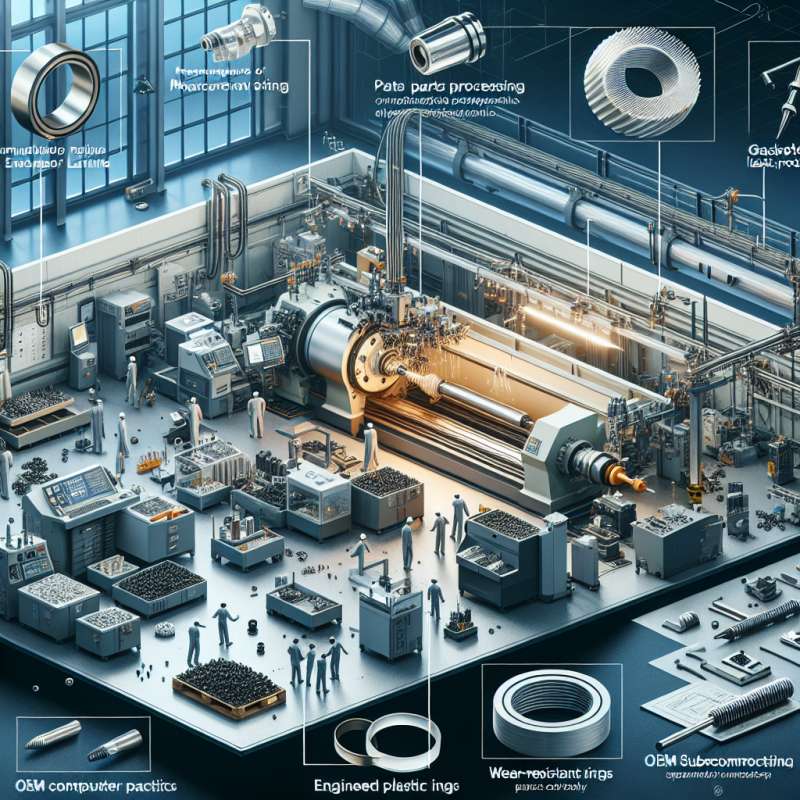

為了確保塑膠板的品質,生產工廠需要配備先進的設備和生產線。常見的生產工藝包括成型、注塑、擠出和熱塑等。塑膠專用機器在這些工藝中發揮著重要作用,幫助生產商提高生產效率和產品質量。

除了品質控制外,環保也是塑膠板製造過程中需要考慮的重要因素。許多塑膠製品可以回收再利用,減少對環境的影響。同時,廠商和供應商也應該注意塑料廢料的處理,以確保生產過程符合環保要求。

隨著市場需求的增加,塑膠板的使用範圍也在不斷擴大。為了滿足不斷增長的需求,廠商應該密切關注市場發展趨勢,不斷創新產品和生產技術。同時,化學原材料的批發也是一個重要環節,影響著產品的成本和品質。

總的來說,塑膠板製造是一個複雜的過程,需要廠商在原料選擇、生產工藝和品質控制上下足功夫。只有不斷提升產品的品質和環保性,才能贏得消費者的信任和市場的競爭力。

Keywords: plastic sheet, manufacturing, production, raw materials, quality control

Title: Quality Control in Plastic Sheet Manufacturing

Article: Plastic sheets are a common plastic product widely used in construction, packaging, furniture, and other industries. In the manufacturing process of plastic sheets, the selection and quality control of raw materials are crucial. Manufacturers need to ensure that the raw materials used meet relevant standards to ensure the durability and corrosion resistance of the final product.

To ensure the quality of plastic sheets, production factories need to be equipped with advanced equipment and production lines. Common production processes include molding, injection molding, extrusion, and thermoforming. Plastic-specific machines play a vital role in these processes, helping manufacturers improve production efficiency and product quality.

In addition to quality control, environmental protection is also an important factor to consider in the manufacturing process of plastic sheets. Many plastic products can be recycled to reduce environmental impact. At the same time, manufacturers and suppliers should also pay attention to the disposal of plastic waste to ensure that the production process meets environmental requirements.

With the increasing market demand, the scope of plastic sheet applications is constantly expanding. To meet the growing demand, manufacturers should closely monitor market trends and continuously innovate products and production technologies. Wholesale of chemical raw materials is also a crucial link that affects product cost and quality.

In conclusion, plastic sheet manufacturing is a complex process that requires manufacturers to focus on raw material selection, production processes, and quality control. Only by continuously improving product quality and environmental friendliness can manufacturers gain consumer trust and market competitiveness.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)