關鍵字: 電力機械器材維修、設備安裝、金屬加工機械

標題: 高效率的電力機械器材維修與設備安裝,提升生產力

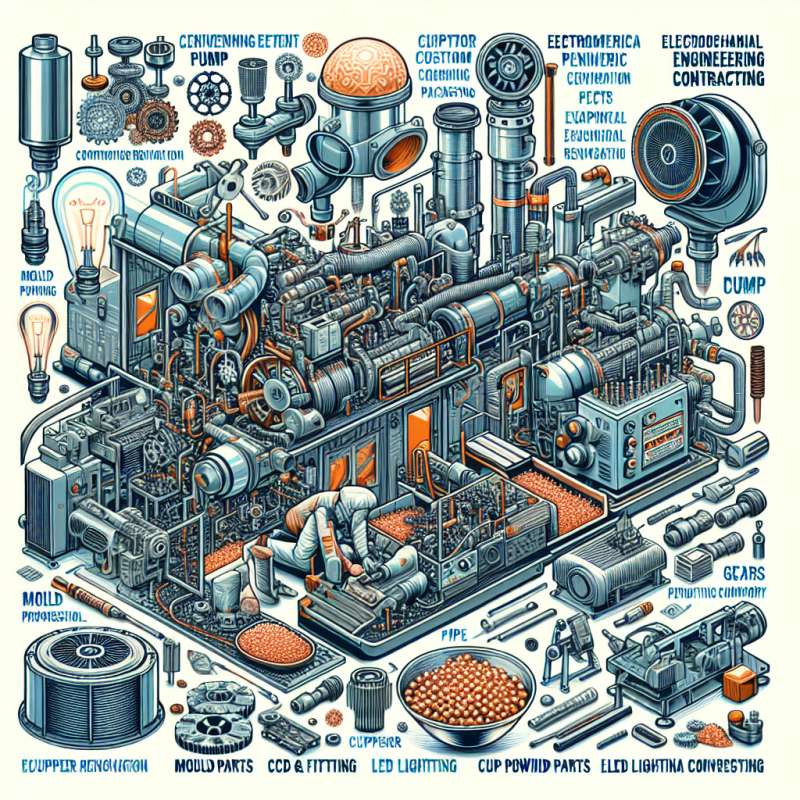

在現代化的工業社會中,電力機械器材維修與設備安裝是確保生產順利進行的關鍵環節。無論是設備維護、機械維修或是器材安裝,都是必不可少的工作。本文將重點介紹如何進行高效率的電力機械器材維修與設備安裝,以提升生產力。

首先,電力機械器材維修是為了確保機械設備的正常運轉而進行的工作。為了做到高效率的維修,我們需要擁有豐富的維修經驗和專業知識。當一台機械設備出現故障時,我們需要迅速判斷問題所在,並採取相應的維修措施。在維修過程中,我們需要使用到各種工具和設備,例如金屬加工機械,以修復或更換損壞的零件。通過定期的維修保養,我們可以延長機械設備的使用壽命,減少生產停機時間,提高生產效率。

而良好的設備安裝也是保證生產順利進行的重要環節。在進行設備安裝之前,我們需要進行詳細的規劃和準備工作。首先,我們需要確定設備的位置和安裝方式,並準備好所需的工具和材料。在安裝過程中,我們需要遵循相關的安全操作標準,確保設備的穩定性和正確性。設備安裝完成後,我們需要進行測試和調試,以確保設備能夠正常運轉。只有通過嚴格的安裝流程,才能確保設備的高效運行,提高生產效率。

綜上所述,電力機械器材維修與設備安裝是確保生產順利進行的重要環節。通過高效率的維修和安裝工作,我們可以提升生產力,減少生產停機時間,增加生產產量。因此,我們應該重視這些工作,加強相關的專業知識和技能培訓,以提升企業的競爭力。

關鍵字: Electric machinery and equipment maintenance, Equipment installation, Metal processing machinery

Title: Efficient Maintenance and Installation of Electric Machinery and Equipment to Enhance Productivity

Article: In modern industrial society, the maintenance and installation of electric machinery and equipment are crucial aspects to ensure smooth production processes. Whether it is equipment maintenance, mechanical repairs, or equipment installation, these tasks are indispensable. This article will focus on how to carry out efficient maintenance and installation of electric machinery and equipment to enhance productivity.

Firstly, electric machinery and equipment maintenance is performed to ensure the proper functioning of machinery. To achieve high efficiency in maintenance, one must possess extensive repair experience and professional knowledge. When a piece of machinery encounters a malfunction, it is essential to quickly identify the issue and implement appropriate repair measures. During the repair process, various tools and equipment, such as metal processing machinery, are utilized to fix or replace damaged components. Through regular maintenance and upkeep, the lifespan of machinery can be prolonged, reducing production downtime and improving productivity.

Furthermore, proper equipment installation is also a crucial aspect in ensuring smooth production processes. Before carrying out equipment installation, detailed planning and preparation are necessary. Firstly, the position and installation method of the equipment must be determined, along with the readiness of required tools and materials. During the installation process, adherence to relevant safety standards is crucial to ensure equipment stability and correctness. Once the installation is completed, testing and debugging are performed to ensure the equipment operates properly. Only through stringent installation procedures can efficient equipment operation be guaranteed, thereby enhancing productivity.

In conclusion, the maintenance and installation of electric machinery and equipment are crucial aspects in ensuring smooth production processes. Through efficient maintenance and installation work, productivity can be enhanced, production downtime reduced, and production output increased. Therefore, it is essential to prioritize these tasks and strengthen relevant professional knowledge and skill training to enhance a company's competitiveness.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)