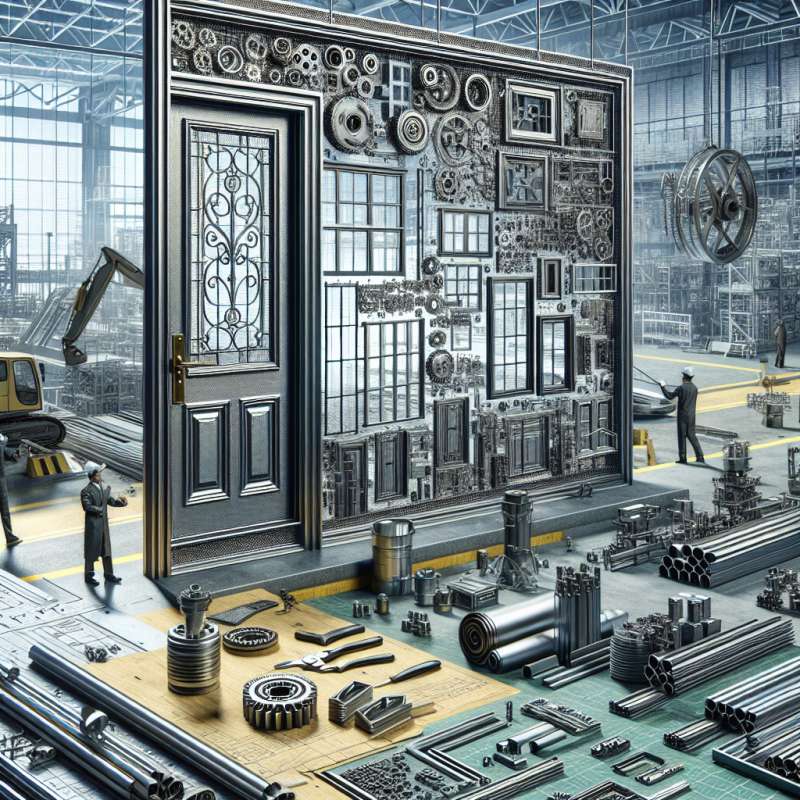

自動化捲窗工廠是一個使用最新技術的製造工廠,專門製造金屬門窗(框)和相關配件。該工廠位於台中市,以自動化系統和成型機為核心,實現高效率和高品質的生產。

在這個工廠,自動化是一個非常重要的關鍵字。通過使用自動化設備,如馬達和機器,工人可以減少重複性和危險性工作的時間,提高生產效率和安全性。例如,捲窗的製造可以通過自動化機器完成,從而節省了大量的時間和人力成本。

另一個關鍵字是生產線。自動化捲窗工廠擁有完善的生產線,從原材料到最終產品的製造過程中,每個步驟都經過精心安排和控制。這些生產線不僅提高了生產效率,還確保了成品的質量和一致性。

在這個工廠中,成型機是一項很重要的技術。成型機是一種可以將金屬材料按照預定形狀製造的機器。通過使用最新的成型機技術,工廠能夠生產出各種形狀的金屬門窗(框)和相關配件,滿足不同客戶的需求。

除了自動化和成型機技術外,另一個關鍵字是配件。配件在自動化捲窗工廠中起著關鍵作用,例如門窗的機械部件和控制系統。這些配件需要精密製造和安裝,以確保捲窗的正常運行和安全性。

以自動化捲窗工廠為核心,該工廠還擁有金屬用車床、銑床和鑽床等製造設備。這些設備的使用,使工廠能夠進行各種金屬製品的生產,包括金屬門窗(框)製造和配件的製造。

最後,該工廠還有電梯、電扶梯和升降機裝修工程的部門。通過該部門,工廠能夠提供電梯等設備的安裝和維修服務,為客戶提供全方位的解決方案。

總之,自動化捲窗工廠以成型機技術為核心,並結合最新的自動化設備和配件生產線,實現高效率和高品質的生產。這些技術和設備不僅提高了生產效率,還確保了產品的質量和安全性。同時,該工廠還提供電梯等設備的裝修和維修服務,為客戶提供全面的解決方案。

關鍵字: Automation, motor, roller blinds, production line, factory, Taichung, components, machining center, metal door and window (frame) manufacturing, metal lathe, milling machine, drilling machine.

Title: Automation of Roller Blind Factory: Latest Technology in Forming Machines

Article:

An automated roller blinds factory located in Taichung City specializes in manufacturing metal door and window (frame) and related components using cutting-edge technology. The factory's core operations revolve around automation systems and forming machines, ensuring high efficiency and quality production.

Automation is a crucial keyword in this factory. By utilizing automated equipment such as motors and machines, workers can minimize time spent on repetitive and hazardous tasks, thereby improving production efficiency and safety. For instance, the production of roller blinds can be completed using automated machines, saving a significant amount of time and labor costs.

Another important keyword is "production line." The automated roller blinds factory boasts a well-designed production line that meticulously controls and organizes each step from raw material to finished product. These production lines not only enhance production efficiency but also ensure product quality and consistency.

In this factory, forming machines play a vital role as a key technology. Forming machines are capable of shaping metal materials into predetermined forms. Through the utilization of the latest forming machine technology, the factory can produce various shapes of metal door and window (frame) and related components, meeting diverse customer demands.

Apart from automation and forming machine technology, another keyword is "components." Components play a critical role within the automated roller blinds factory, such as mechanical parts and control systems of doors and windows. These components necessitate precision manufacturing and installation to ensure the smooth operation and safety of roller blinds.

Centered around the automated roller blinds factory, the complex is equipped with manufacturing machinery such as metal lathes, milling machines, and drilling machines. These machines enable the production of various metal products, including metal door and window (frame) manufacturing and component production.

Finally, the factory also houses an elevator, escalator, and lift installation and maintenance department. Through this department, the factory provides installation and maintenance services for elevators and other equipment, offering comprehensive solutions to customers.

In summary, the automation of the roller blinds factory, incorporating the core technology of forming machines alongside state-of-the-art automated equipment and component production lines, enables high efficiency and quality production. These technologies and machines not only enhance production efficiency but also ensure product quality and safety. Moreover, the factory provides comprehensive installation and maintenance services for elevators and other equipment, delivering holistic solutions to customers.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)