工業製造領域中,橡膠製品是一種非常常見且重要的產品。橡膠製品製造的生產線以及製造工藝,在製造過程中扮演著關鍵的角色。本文將介紹工業橡膠製品的生產線及相關製造工藝。

在工業製造領域中,橡膠製品製造商通常會運用先進的製造工藝和高效的生產線,以確保產品的品質和產能。製造工藝是指在製造過程中所採用的技術和方法,包括橡膠材料的配方、製造設備的使用和製程控制等。這些工藝決定了橡膠製品的品質和性能。

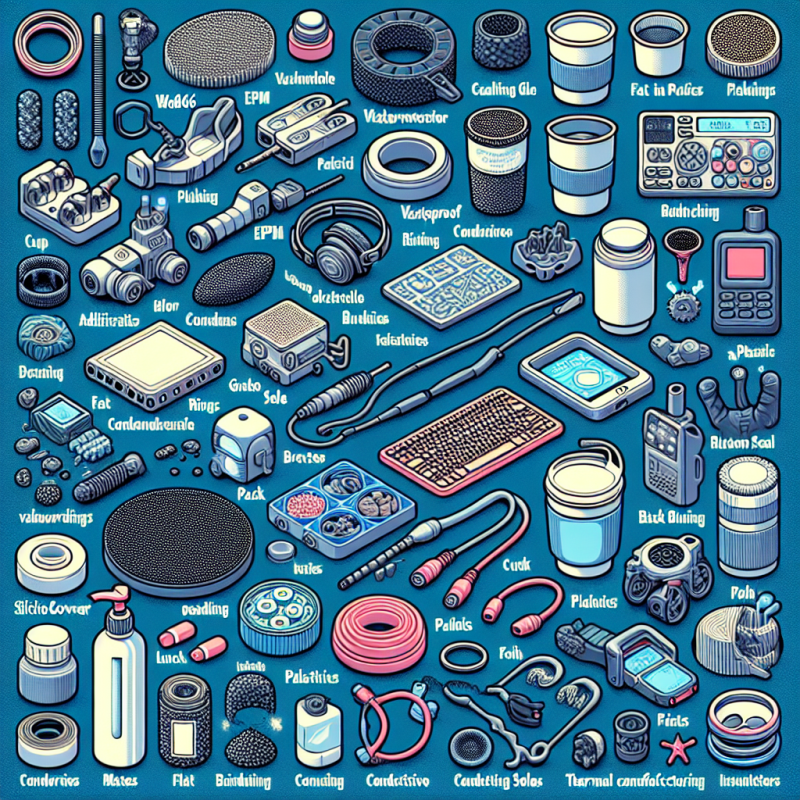

生產線是指在橡膠製品生產過程中所使用的一系列設備和機器,這些設備和機器通常包括原料處理機、混煉機、壓延機、模具和硫化爐等。這些設備和機器的運作協同作業,從原料處理到橡膠產品成型並進行硫化處理。

橡膠製品的生產過程一般包括以下幾個步驟:原料選擇、材料混合、成型、硫化、修整和檢測。首先,橡膠製品製造商需要選擇適用於特定應用的橡膠材料,並根據需求混合不同成分的材料。接著,混合好的橡膠材料經過成型工藝,通過模具成型成為所需的形狀。然後,製品需要進行硫化處理,以改善其物理和化學性能。硫化完成後,製品需要進行修整,以去除多餘的邊緣和瑕疵。最後,製品需要進行檢測,以確保其品質符合標準。

在橡膠製品的生產過程中,品質控制是至關重要的一環。製造商需要對每個生產步驟進行嚴格的控制和檢測,以確保產品品質的一致性和穩定性。這包括控制原料的品質、機器的運作參數以及產品的尺寸和外觀等方面。

除了品質控制外,生產效率和成本控制也是工業橡膠製品製造商關注的重點。他們通過優化生產線和改進製造工藝,以提高生產效率並降低成本。這包括產能規劃、製品設計和橡膠技術的改進等。

總結而言,工業橡膠製品的生產線和製造工藝在橡膠製品製造過程中扮演著重要的角色。製造商需要運用先進的製造工藝和高效的生產線,並進行品質控制和成本控制,以確保產品的品質和競爭力。

關鍵字: Rubber products, Industrial manufacturing, Production line

Title: Production Line and Manufacturing Process of Industrial Rubber Products

Article:

Rubber products are commonly seen and crucial in industrial manufacturing. The production line and manufacturing process of rubber products play a vital role in the manufacturing industry. This article will introduce the production line and related manufacturing processes of industrial rubber products.

In the field of industrial manufacturing, manufacturers of rubber products usually utilize advanced manufacturing processes and efficient production lines to ensure product quality and capacity. The manufacturing process refers to the techniques and methods adopted during the manufacturing process, including rubber material formulations, the use of manufacturing equipment, and process control. These processes determine the quality and performance of rubber products.

A production line is a series of equipment and machines used in the production process of rubber products, which typically include material handling machines, mixing mills, calenders, molds, and vulcanizers. These equipment and machines work together from raw material processing to rubber product molding and vulcanization.

The production process of rubber products generally includes several steps: material selection, material mixing, molding, vulcanization, trimming, and testing. Firstly, manufacturers of rubber products need to choose rubber materials suitable for specific applications and mix materials with different compositions accordingly. Then, the mixed rubber materials go through the molding process to take the desired shape using molds. Next, the products require vulcanization to enhance their physical and chemical properties. After vulcanization, the products need to be trimmed to remove excess edges and defects. Finally, the products undergo testing to ensure their quality meets the standards.

Quality control is of paramount importance throughout the production process of rubber products. Manufacturers need to exercise strict control and testing for each production step to ensure consistent and stable product quality. This includes controlling the quality of raw materials, machine operating parameters, and product dimensions and appearance.

Apart from quality control, production efficiency and cost control are also key concerns for manufacturers of industrial rubber products. They strive to enhance production efficiency and reduce costs by optimizing production lines and improving manufacturing processes. This includes capacity planning, product design, and improvements in rubber technology.

In conclusion, the production line and manufacturing process of industrial rubber products have significant roles in the manufacturing process. Manufacturers need to employ advanced manufacturing processes and efficient production lines, while conducting quality control and cost control, to ensure product quality and competitiveness.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)