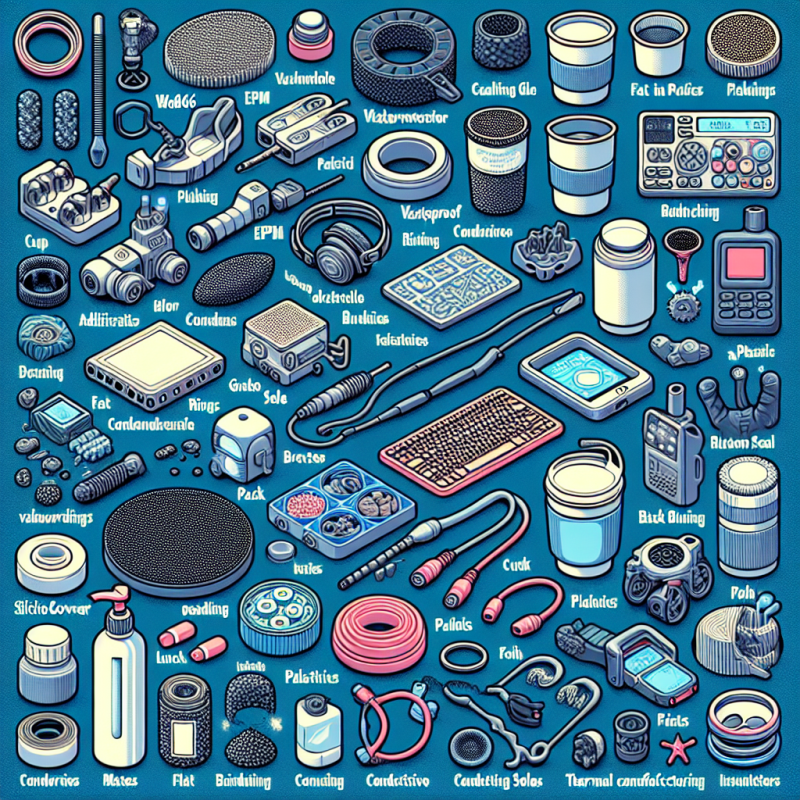

橡膠製品在現代工業中扮演著重要的角色,常被用於橡膠油壓機OUV、半導體線鋸機滾輪、以及PU零件和矽橡膠製品的製造中。這些製品在不同的應用領域中發揮著關鍵作用。

橡膠油壓機OUV是一種常見的工業設備,使用橡膠與鐵材結合,用於加工和成型金屬材料。它的耐化學酸鹼滾輪能夠抵抗腐蝕,確保機器長久使用。

半導體線鋸機滾輪是半導體工業中至關重要的組件。使用PU材料製成的切割件,能夠提供高度的精度和穩定性,確保半導體元件的切割過程。

PU零件和矽橡膠製品在工業中廣泛應用。PU零件具有耐磨耗、耐油和耐化學腐蝕的特性,常用於機械設備和工業設備的組件中。矽橡膠製品因其耐高溫、耐腐蝕和優良的彈性而被廣泛使用於半導體、電子和航空等領域。

這些製品的製造和應用需要優質的材料和精密的加工技術。提供清潔電容鋁泊滾輪的清洗工作,使材料表面保持清潔,以確保產品質量。而HOT護貝加熱軸則能夠為特定應用中的軸心部分加熱,確保設備正常運行。

此外,紡織抗靜電滾輪、半導體用PTFE、橡膠塗鐵氟龍等特殊要求的橡膠滾輪也應用廣泛。這些製品通過選用不同的材料和處理工藝,以滿足不同場景下的需求。

工業用橡膠製品的製造在現代工業中扮演著重要的角色。無論是USB保護套、耐300度快乾輪,還是具有特殊功能的半導體線鋸機滾輪,它們都是基於橡膠材料的創新應用。橡膠產品的製造和應用為各個行業提供了多種解決方案,同時也使得現代科技得以不斷發展。

關鍵字:Rubber oil press machine OUV, PU parts, Semiconductor wire saw machine rollers, Silicon rubber products

標題:Manufacturing and Application of Industrial Rubber Products

Rubber products play an important role in modern industry and are commonly used in the manufacturing of rubber oil press machines OUV, semiconductor wire saw machine rollers, PU parts, and silicon rubber products. These products serve crucial functions in various application fields.

The rubber oil press machine OUV is a common industrial equipment that combines rubber with iron to process and shape metal materials. Its chemical-resistant acid and alkali rollers ensure the longevity of the machine by resisting corrosion.

Semiconductor wire saw machine rollers are vital components in the semiconductor industry. The cutting parts made of PU material provide high precision and stability during the process of cutting semiconductor components.

PU parts and silicon rubber products are widely used in the industry. PU parts offer wear resistance, oil resistance, and chemical corrosion resistance, making them suitable for components in machinery and industrial equipment. Silicon rubber products are popular due to their high-temperature resistance, corrosion resistance, and excellent elasticity, making them suitable for applications in semiconductors, electronics, aerospace, and other fields.

The manufacturing and application of these products require high-quality materials and precise processing techniques. Cleaning the capacitor aluminum foil rollers ensures a clean surface, guaranteeing product quality. The HOT protective shell heating shaft heats the central part of specific applications to ensure the normal operation of the equipment.

In addition, special requirements for rubber rollers, such as textile anti-static rollers, semiconductor PTFE rollers, and rubber-coated iron fluoropolymer rollers, are widely applied. These products meet different needs in various scenarios by selecting different materials and processing techniques.

The manufacturing of industrial rubber products plays an important role in modern industry. Whether it is a USB protective case, a 300-degree heat-resistant quick-drying wheel, or a wire saw machine roller with special functions, they are all innovative applications based on rubber materials. The manufacturing and application of rubber products provide various solutions for different industries and contribute to the continuous development of modern technology.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)