隨著現代科技的進步,鋁件製造已成為眾多行業中不可或缺的一環。鋁及鋁合金作為一種輕量且耐腐蝕的材料,具有廣泛的應用價值。本文將介紹鋁件製造的基本過程,以及粗製品的特點。

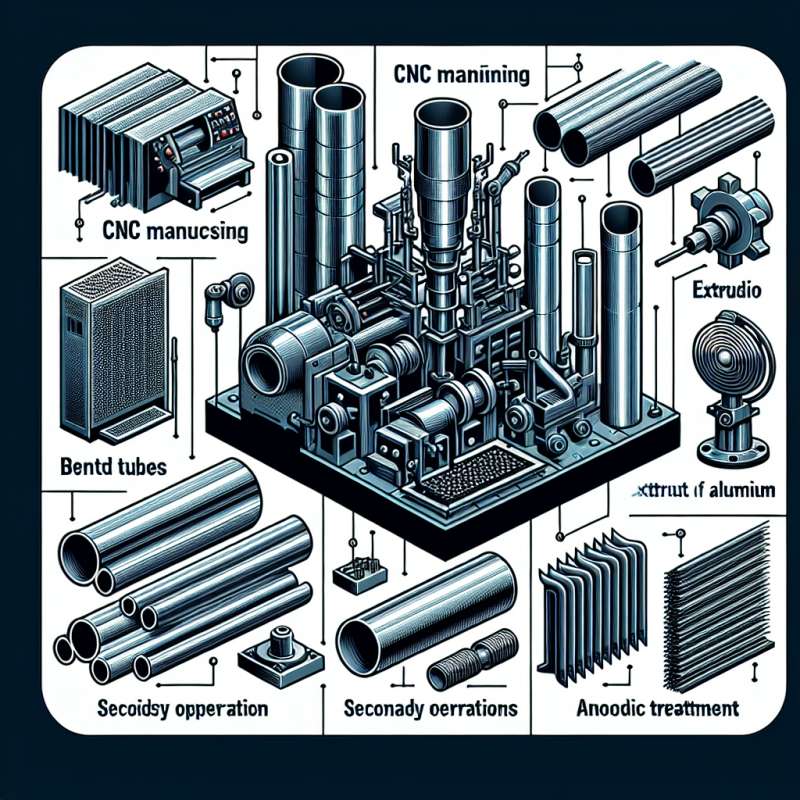

鋁件製造是指利用鋁及鋁合金材料進行各種零部件的製造過程。該過程通常包括以下幾個基本步驟:原材料選擇、材料切割、成型加工和表面處理。基於不同的應用需求,鋁件製造可以選擇不同的製造方法,例如鑄造、壓延、鍛造等。

鋁及鋁合金材料具有較低的密度和良好的韌性,因此在許多行業中廣泛應用。鋁件具有較高的強度和剛性,同時具有抗腐蝕和耐磨損的特點,適合在汽車、航空航天、建築和電子等領域中使用。鋁件製造的成本相對較低,且容易進行加工和組裝,因此受到廣泛的歡迎。

粗製品是指在鋁件製造過程中的一個重要階段,它是指製造過程中還未經過精密加工和表面處理的組件。粗製品通常具有較大的尺寸和粗糙的表面,需要進一步加工才能成為最終的成品。粗製品可以通過切割、銑削、鑽孔等方式進行加工,以滿足不同應用的需求。在鋁件製造過程中,粗製品扮演著非常重要的角色,確保最終產品的精度和質量。

總結起來,鋁件製造是一個基本但重要的過程。鋁及鋁合金材料的應用廣泛,且鋁件具有較低的成本和良好的性能。粗製品作為鋁件製造過程中的一個階段,需要進一步進行加工和處理才能成為最終的成品。透過不斷的創新和技術進步,鋁件製造將在未來持續發展並發揮更重要的作用。

關鍵字: basic, aluminum component manufacturing, aluminum, aluminum alloy, rough product, manufacturing

標題: The Basic Process of Aluminum Component Manufacturing and the Characteristics of Rough Products

With the advancement of modern technology, aluminum component manufacturing has become an essential part of many industries. Aluminum and aluminum alloys, known for their lightweight and corrosion-resistant properties, have a wide range of applications. This article introduces the basic process of aluminum component manufacturing and the characteristics of rough products.

Aluminum component manufacturing refers to the process of producing various parts using aluminum and aluminum alloy materials. This process typically includes several basic steps: material selection, material cutting, forming processing, and surface treatment. Depending on different application requirements, different manufacturing methods such as casting, rolling, and forging can be chosen for aluminum component manufacturing.

Aluminum and aluminum alloy materials have a lower density and good toughness, making them widely used in many industries. Aluminum components possess higher strength and rigidity, along with corrosion resistance and wear resistance, making them suitable for applications in the automotive, aerospace, construction, and electronics fields. Aluminum component manufacturing has relatively low costs and is easy to process and assemble, making it widely popular.

Rough products are an important stage in the aluminum component manufacturing process. They refer to components that have not undergone precise machining and surface treatment during the manufacturing process. Rough products usually have larger dimensions and rough surfaces, requiring further processing to become the final finished products. Rough products can be processed through cutting, milling, drilling, and other methods to meet the demands of different applications. In the aluminum component manufacturing process, rough products play a crucial role in ensuring the accuracy and quality of the final products.

In conclusion, aluminum component manufacturing is a basic yet important process. Aluminum and aluminum alloy materials are widely used, and aluminum components have low costs and excellent performance. Rough products, as a stage in aluminum component manufacturing, require further processing and treatment to become final finished products. With continuous innovation and technological advancement, aluminum component manufacturing will continue to develop and play a more significant role in the future.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)