在過去的數十年間,木竹製品的製造技術經歷了許多重要的演進。這些演進不僅改進了製品的品質和性能,還為木竹製品的應用帶來了更多可能性。

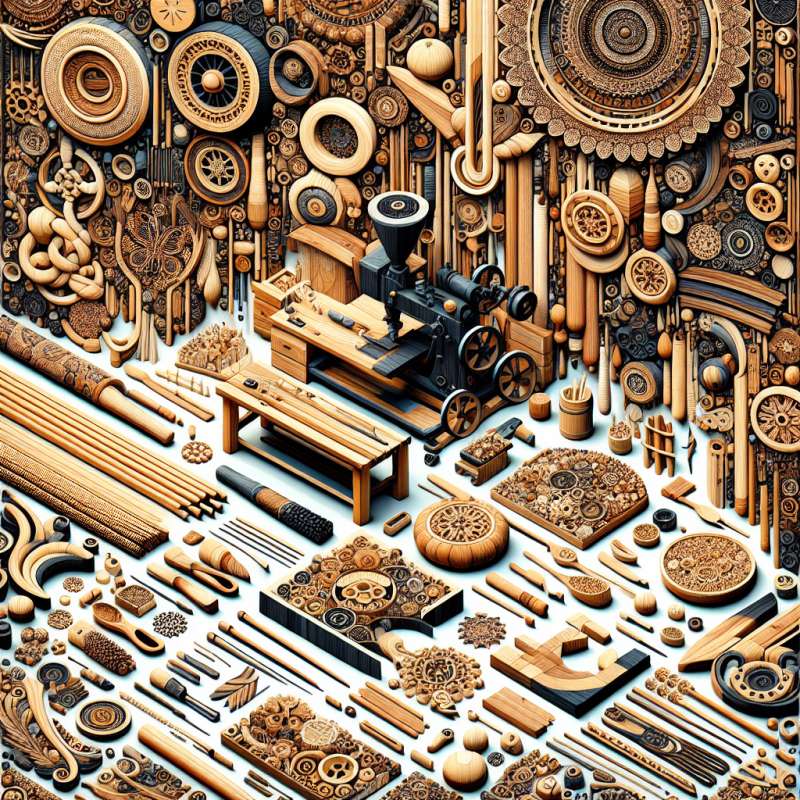

首先,製品的製造過程由傳統的手工製作轉變為機械化的生產。過去,木竹製品的製造依賴於手工技藝,這需要大量的時間和勞動力。然而,隨著科技的進步,現代的製造設備使製品的生產速度大大提高,同時還確保了製品的一致性和質量。

其次,製造過程中使用的材料也進行了改進。過去,木竹製品多數使用天然木竹材料,但這些材料在品質和耐用性方面存在一定的限制。為了解決這個問題,製造商開始使用人工合成材料和增強材料來製作木竹製品。這些新材料不僅可以提供更好的品質和性能,還能夠有效地達到可持續發展和環保的目標。

此外,製造技術的進步也促進了木竹製品的多樣化。過去,木竹製品主要用於建築、家具和工藝品等傳統領域。現在,隨著技術的進步,木竹製品已廣泛應用於汽車、航空航天、運動用品等各個領域。製造商不斷創新和研發新型木竹製品,以滿足市場需求和消費者的多樣化需求。

總結來說,木竹製品的製造技術經歷了從手工製作到機械化生產的轉變,從使用天然材料到人工合成材料的改進,以及從傳統領域到各個行業的擴展。這些演進不僅提高了木竹製品的品質和性能,還創造了更多的商機和應用可能性。

關鍵字: Bamboo, Products, Manufacturing

標題: The Evolution of Bamboo Products Manufacturing

Over the past few decades, the manufacturing technology of bamboo products has undergone significant evolution. These advancements have not only improved the quality and performance of the products, but have also opened up new possibilities for their applications.

Firstly, the production process has shifted from traditional manual craftsmanship to mechanized manufacturing. In the past, bamboo products heavily relied on manual skills, which consumed a lot of time and labor. However, with the progress of technology, modern manufacturing equipment has greatly increased the production speed while ensuring consistency and quality of the products.

Secondly, there has been an improvement in the materials used during the manufacturing process. Natural bamboo materials were primarily used in the past, but these materials had limitations in terms of quality and durability. To overcome this, manufacturers started using synthetic and reinforced materials in bamboo product production. These new materials not only offer better quality and performance, but also help achieve sustainable and environmentally friendly goals.

Additionally, advancements in manufacturing technology have led to a diversification of bamboo products. In the past, bamboo products were mainly used in traditional fields such as construction, furniture, and crafts. Nowadays, with technological advancements, bamboo products are widely applied in various industries including automotive, aerospace, and sports equipment. Manufacturers continuously innovate and develop new types of bamboo products to meet market demands and the diverse needs of consumers.

In conclusion, the manufacturing technology of bamboo products has evolved from manual craftsmanship to mechanized production, from using natural materials to improved synthetic materials, and from traditional fields to diverse industries. These advancements have not only enhanced the quality and performance of bamboo products, but have also created more business opportunities and application possibilities.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)