近年來,塑料成形和鍛造技術在製造業中扮演著重要的角色。塑料成形是一種將熔融的塑料注入模具中,然後冷卻成形的過程。這種技術廣泛應用於製造各種塑料制品,如家電配件、汽車零件等。而鍛造則是一種將金屬加熱至高溫後進行塑性變形的工藝,通常用於製造高強度的金屬零件。

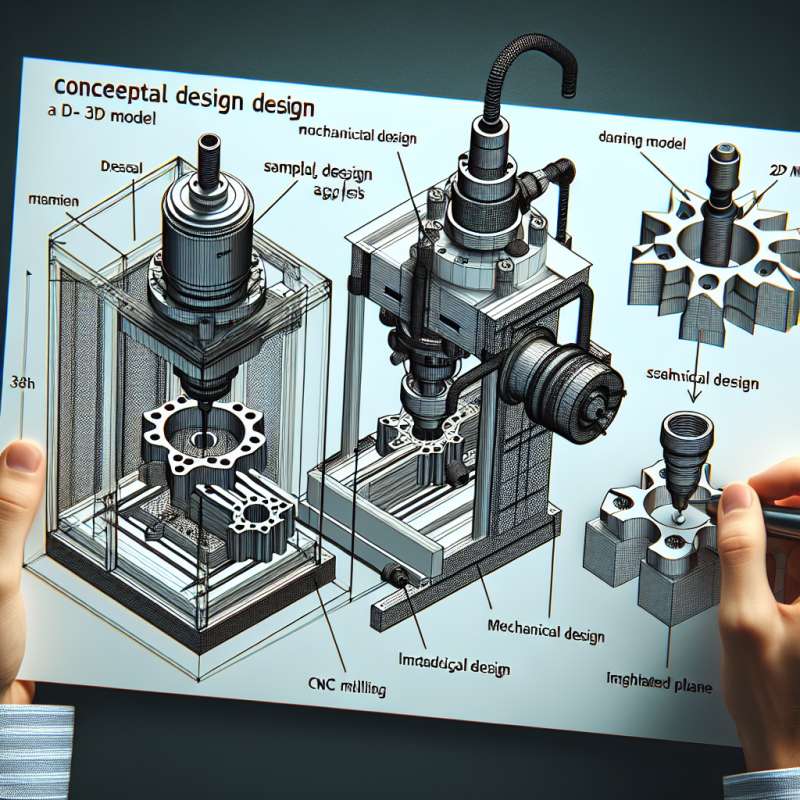

在塑料成形和鍛造過程中,模具設計是至關重要的。一個優秀的模具設計可以確保產品的精確度和質量。此外,還有許多其他相關的製造技術,如冷熔接、焊接、鍍鋅等,這些技術都可以與塑料成形和鍛造相結合,以實現更高效的生產。

塑料成形和鍛造技術的應用不僅局限於製造業,還廣泛應用於機械器具的製造和批發。這些技術的發展不僅提高了產品的質量和效率,還為製造業帶來了更多的商機和競爭優勢。

關鍵字: Plastic molding, Forging, Mold design

Title: Application of Plastic Molding and Forging Technology

Article: In recent years, plastic molding and forging technology have played an important role in the manufacturing industry. Plastic molding is a process of injecting molten plastic into a mold and then cooling it to form a specific shape. This technology is widely used in the production of various plastic products, such as household appliance parts, automotive components, and more. On the other hand, forging is a process of shaping metal by heating it to a high temperature and then deforming it. It is commonly used to manufacture high-strength metal parts.

In the processes of plastic molding and forging, mold design is crucial. A well-designed mold ensures the accuracy and quality of the products. In addition, there are many other related manufacturing technologies, such as cold fusion, welding, galvanizing, etc., which can be combined with plastic molding and forging to achieve more efficient production.

The application of plastic molding and forging technology is not limited to the manufacturing industry, but also widely used in the production and wholesale of mechanical equipment. The development of these technologies has not only improved the quality and efficiency of products but also brought more business opportunities and competitive advantages to the manufacturing industry.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)