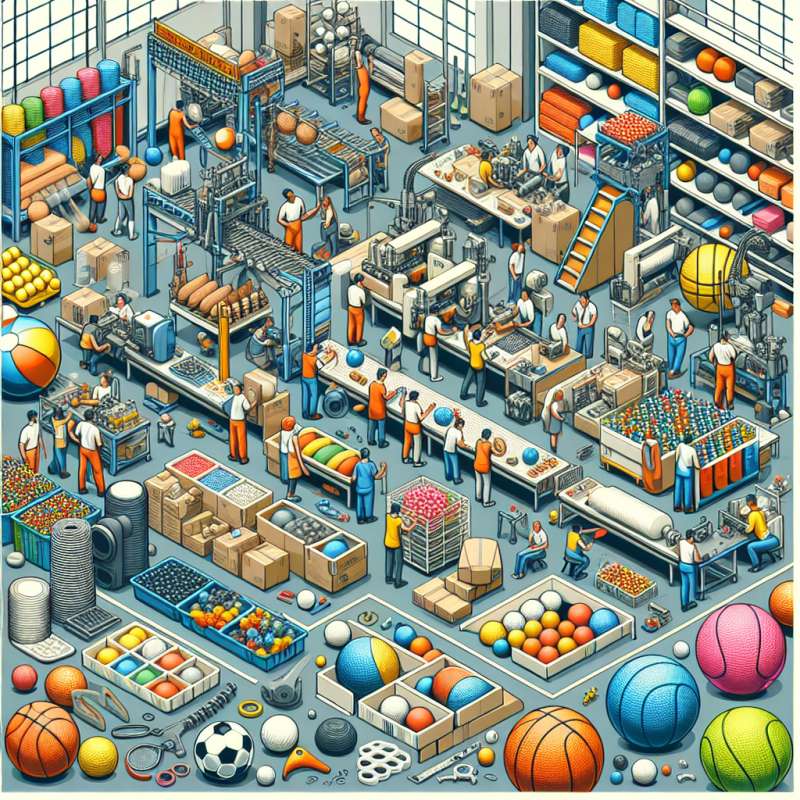

橡膠製品製造工藝是指利用橡膠材料進行生產製造的過程。在橡膠製造工藝中,原料的選擇和橡膠技術的應用至關重要。製程包括橡膠配方的設計、製品設計、生產線的配置以及品質控制等環節。橡膠製品的生產需要先進的設備和高效的生產效率,同時也需要嚴格的製品檢測和成本控制。

產品開發是橡膠行業中至關重要的一環。通過不斷的技術創新和產品開發,橡膠製品能夠不斷滿足市場需求。在產品開發過程中,應該充分考慮橡膠材料的特性和製造工藝的可行性,同時也需要對產品的功能和品質進行全面的評估。

橡膠製造工藝和產品開發的成功需要擁有強大的橡膠技術和豐富的製造經驗。同時,應該對產能進行合理的規劃,以確保生產線的穩定運行和產品的高質量。橡膠廠應該注重產品開發和製造工藝的不斷改進,以提高產品的競爭力和市場占有率。

關鍵字: Rubber products, manufacturing process, product development

Title: Rubber Product Manufacturing Process and Product Development

Article: The manufacturing process of rubber products refers to the process of production using rubber materials. In the manufacturing process of rubber products, the selection of raw materials and the application of rubber technology are crucial. The process includes the design of rubber formulations, product design, the configuration of production lines, and quality control. The production of rubber products requires advanced equipment and high production efficiency, as well as strict product testing and cost control.

Product development is a crucial part of the rubber industry. Through continuous technological innovation and product development, rubber products can continuously meet market demand. In the product development process, the characteristics of rubber materials and the feasibility of manufacturing processes should be fully considered, and a comprehensive evaluation of the functionality and quality of the product should also be conducted.

The successful manufacturing process and product development of rubber require strong rubber technology and rich manufacturing experience. At the same time, reasonable planning of production capacity should be carried out to ensure the stable operation of the production line and the high quality of the product. Rubber plants should focus on continuous improvement in product development and manufacturing processes to enhance the competitiveness and market share of their products.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)