近年來,OEM(原始設備製造商)工業機械和腳踏車零件的市場需求不斷增長。這一市場的關鍵材料包括不銹鋼和鋁合金,它們在製造工業機械和腳踏車零件中發揮著重要的角色。

不銹鋼是一種耐蝕、耐高溫和強度優越的材料。它廣泛應用於食品、製藥和化工等行業,同時也是工業機械和腳踏車零件的理想選擇。在OEM機械製造中,不銹鋼可以用於生產螺栓、螺母、軸承和其他關鍵零部件。而在腳踏車製造方面,使用不銹鋼可以增加零件的耐用性和抗腐蝕性,同時降低維護成本。

另一方面,鋁合金是一種輕量、高強度的材料,用於製造腳踏車和工業機械時非常受歡迎。鋁合金輪框、踏板、把手和其他結構零件可以提供更好的操控性和耐用性。此外,鋁合金具有良好的熱導性,有助於散熱,保護機械設備免受過熱損壞。

隨著全球工業化和城市化進程的推進,OEM工業機械和腳踏車的需求不斷增長。建築、交通運輸和農業等行業對這些產品的需求不斷增加,從而推動了不銹鋼和鋁合金的市場需求增長。與此同時,在全球經濟一體化的背景下,許多工業機械和腳踏車製造商選擇進口優質零件,進一步促進了不銹鋼和鋁合金的出口市場。

總之,隨著市場需求的增長,OEM工業機械和腳踏車零件的生產將依賴於高品質的不銹鋼和鋁合金。這兩種材料具有良好的耐久性、耐腐蝕性和強度,能夠滿足不同行業的需求。同時,全球市場的擴大和國際貿易的增加也為不銹鋼和鋁合金的製造商提供了更多的市場機會。

Keywords: OEM, Stainless Steel, Industrial, Aluminum Alloy, Bicycle, Machinery

Title: Market Demand Growth: Stainless Steel and Aluminum Alloy for OEM Industrial Machinery and Bicycle Parts

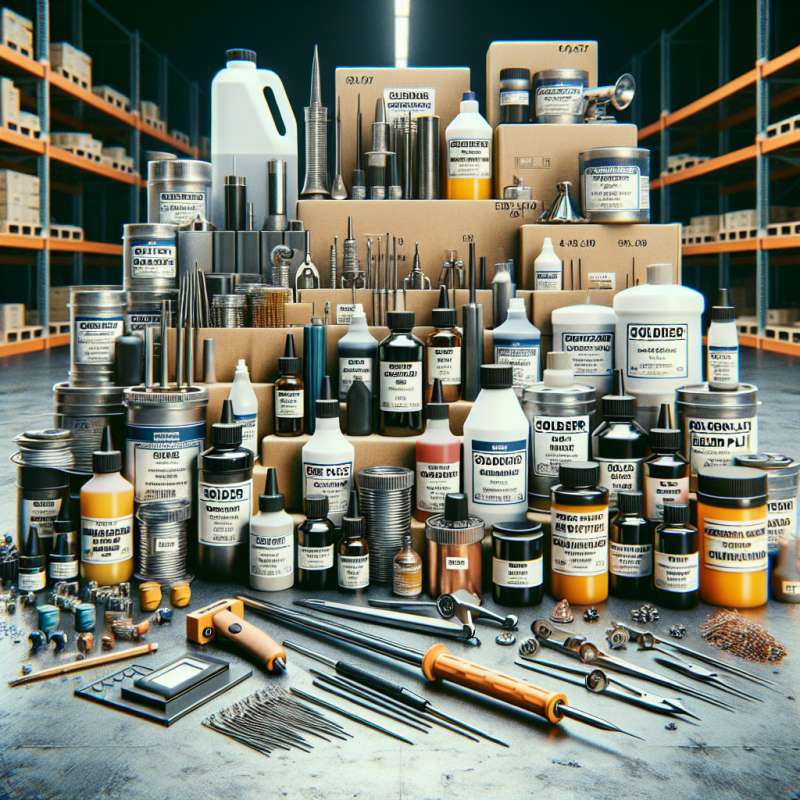

Article: In recent years, the market demand for OEM (Original Equipment Manufacturer) industrial machinery and bicycle parts has been continuously growing. The key materials in this market include stainless steel and aluminum alloy, which play a crucial role in manufacturing industrial machinery and bicycle parts.

Stainless steel is a corrosion-resistant, heat-resistant, and high-strength material. It is widely used in industries such as food, pharmaceuticals, and chemicals, making it an ideal choice for manufacturing industrial machinery and bicycle parts. In OEM machinery production, stainless steel can be used to produce bolts, nuts, bearings, and other crucial components. In bicycle manufacturing, the use of stainless steel can increase part durability and corrosion resistance while reducing maintenance costs.

On the other hand, aluminum alloy is a lightweight and high-strength material that is highly favored in the production of bicycles and industrial machinery. Aluminum alloy wheel rims, pedals, handlebars, and other structural parts provide better control and durability. Additionally, aluminum alloy has excellent thermal conductivity, aiding in heat dissipation and protecting machinery from overheating damage.

With the progress of global industrialization and urbanization, the demand for OEM industrial machinery and bicycles continues to grow. Industries such as construction, transportation, and agriculture have witnessed an increasing demand for these products, driving the market demand for stainless steel and aluminum alloy. Meanwhile, in the context of global economic integration, many industrial machinery and bicycle manufacturers choose to import high-quality parts, further promoting the export market for stainless steel and aluminum alloy.

In conclusion, with the growth in market demand, the production of OEM industrial machinery and bicycle parts will rely on high-quality stainless steel and aluminum alloy. These two materials offer excellent durability, corrosion resistance, and strength, meeting the needs of various industries. Simultaneously, the expansion of the global market and increased international trade provide more market opportunities for stainless steel and aluminum alloy manufacturers.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)